A kind of slag crushing device of household oil press and preparation material thereof

An oil press and crushing technology, which is applied in the field of crushing devices and its preparation materials, can solve the problems of short service life, machine interruption damage, low strength, etc., to save Ni resources, improve tensile strength, and improve yield intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

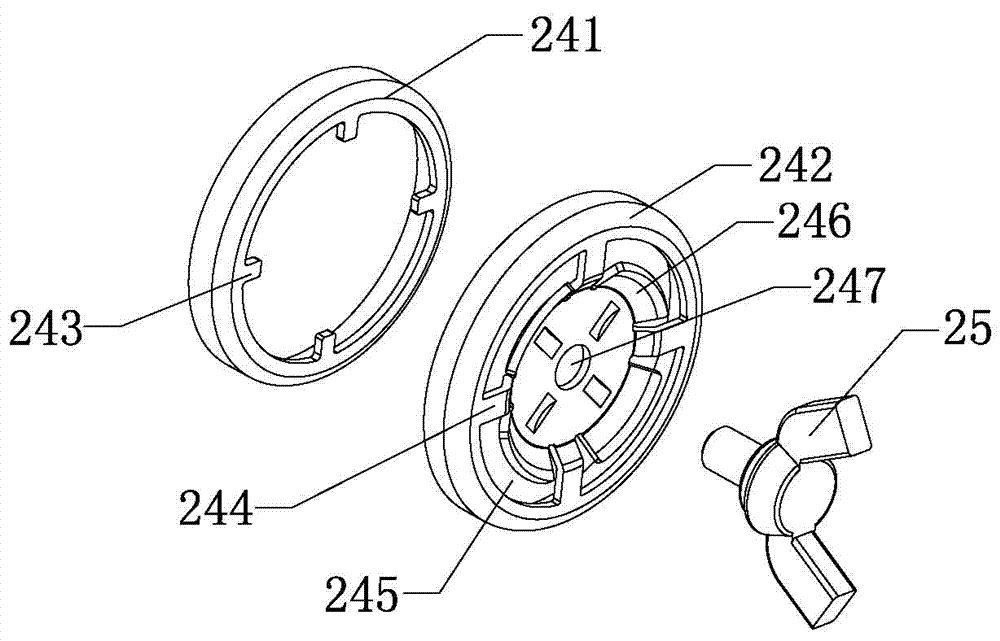

[0078] See Figure 1~2 , a crushing device for a household oil press, the crushing device includes a fixed part 241 fixed to the end of the press chamber 11 and a rotating part 242 fixed to the end of the squeeze rod 12 of the household oil press, and the inside of the fixed part 241 is fixed There is at least one first scraper 243 , and at least one second scraper 244 is fixed on the rotating part 242 .

[0079] In this embodiment, four first scrapers 243 are fixed inside the fixed part 241, and the four first scrapers 243 are distributed in a circular array; the rotating part 242 is fixed with four second scrapers 244, and the four second scrapers The scrapers 244 are distributed in a circular array, and a slag leakage groove 245 is formed between the four second scraper blades 244 , and the inner edge of the slag leakage groove 245 is bent to the right to form a rolled portion 246 .

[0080] In this embodiment, a mounting hole 247 is opened in the middle of the rotating pa...

Embodiment 2

[0091] The difference between this embodiment and the above-mentioned embodiment 1 is:

[0092]A high-strength stainless steel material used in the above slag breaking device, its chemical composition includes the following elements by weight: C: 0.4%, N: 0.18%, Si: 0.25%, Mn: 1.8%, Cr: 10.5%, Ni : 2.2%, Cu: 1.4%, V: 0.8%, B: 0.2%, Mo: 0.15%, Ca: 0.09%, Zr: 0.04%, P≤0.010%, S≤0.004%, H≤0.004%, O ≤0.002%, the balance is iron.

[0093] A method for preparing a high-strength stainless steel material, comprising the steps of:

[0094] A. Smelting: According to the ratio of the above chemical components, the double smelting process of hydrogen-oxygen decarburization furnace and intermediate frequency induction furnace is used for smelting to obtain molten steel;

[0095] B. Continuous casting: The molten steel obtained in step A is continuously cast into castings under stirring conditions, and the castings are slowly cooled at a rate of 32°C / h, and then thermally ground at a temp...

Embodiment 3

[0104] The difference between this embodiment and the above-mentioned embodiment 1 is:

[0105] A high-strength stainless steel material used in the above slag breaking device, its chemical composition includes the following elements by weight: C: 0.5%, N: 0.15%, Si: 0.3%, Mn: 1.5%, Cr: 11%, Ni : 2%, Cu: 1.6%, V: 0.7%, B: 0.3%, Mo: 0.2%, Ca: 0.1%, Zr: 0.03%, P≤0.008%, S≤0.003%, H≤0.003%, O ≤0.001%, the balance is iron.

[0106] A method for preparing a high-strength stainless steel material, comprising the steps of:

[0107] A. Smelting: According to the ratio of the above chemical components, the double smelting process of hydrogen-oxygen decarburization furnace and intermediate frequency induction furnace is used for smelting to obtain molten steel;

[0108] B. Continuous casting: The molten steel obtained in step A is continuously cast into castings under stirring conditions, and the castings are slowly cooled at a rate of 35°C / h, and then thermally ground at a temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com