Method for preparing steel-based copper-alloy thermometal spherical bearing seat blank

A spherical bearing seat, copper alloy technology, applied in the field of special casting, can solve the problems of low production efficiency, poor labor intensity and high temperature working environment, and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The preparation method sequentially includes:

[0046] Perform technological pretreatment on the steel shell 2;

[0047] Fix the pretreated steel shell 2 on the turntable 4 of the vertical centrifugal casting machine with the open end of the steel shell 2 facing upwards, and correct the concentricity of the steel shell 2 and the turntable 4;

[0048] Add process quantities of copper alloy particles and copper gas flux to the inner cavity of the steel shell 2; start the vertical centrifugal casting machine turntable 4 to make the copper alloy particles and copper gas flux cover the inner spherical surface of the steel shell;

[0049] Start the electric induction heating setting 5 to raise the temperature of the steel shell 2 until the copper alloy particles attached to the inner spherical surface of the steel shell 2 are all melted into liquid, then shut down the electric induction heating device 5 and rise and exit the working position;

[0050] The steel shell 2 is cooled; while...

example 1

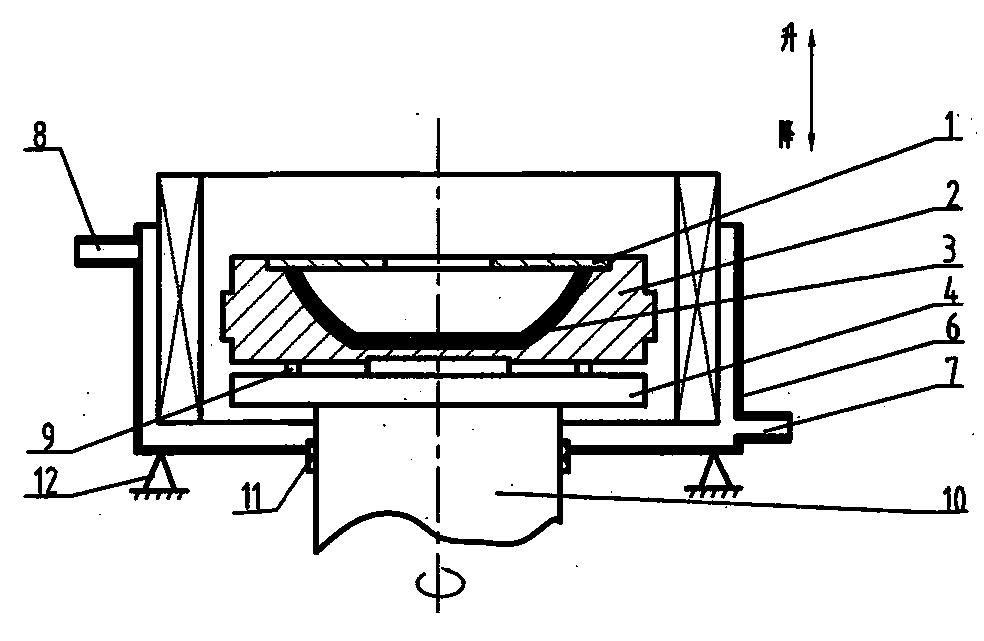

[0065] Please refer to the attached figure 1 . Preparation of the upper cover of the spherical bearing seat of the large-scale marine combined piston.

[0066] The outline size of the upper cover of the spherical bearing seat: such as Figure 4 Shown. According to the outline size, make a steel shell of corresponding size and shape;

[0067] a ) Ingredients: 6Kg copper alloy particles (a mixture with a particle size of 0.5~1.0mm) and 400g copper gas flux are mixed, and the surface of the above mixture is covered with 30g wood carbon powder.

[0068] b) Casting process: 1) Move from top to bottom into the electric induction heating device 5, 2) Use 60Kw power at 160r / min to heat for 2.5min; 3) Adjust the power to 80Kw and heat for 44min; 4) Adjust the power to 50Kw heating for 5min; 5) Adjust the power to 0Kw, move up the electric induction heating device 5, air cooling for 3 minutes, 6) Introduce cooling water to the cooling water tank 6, and water cooling for 12 minutes. There is...

example 2

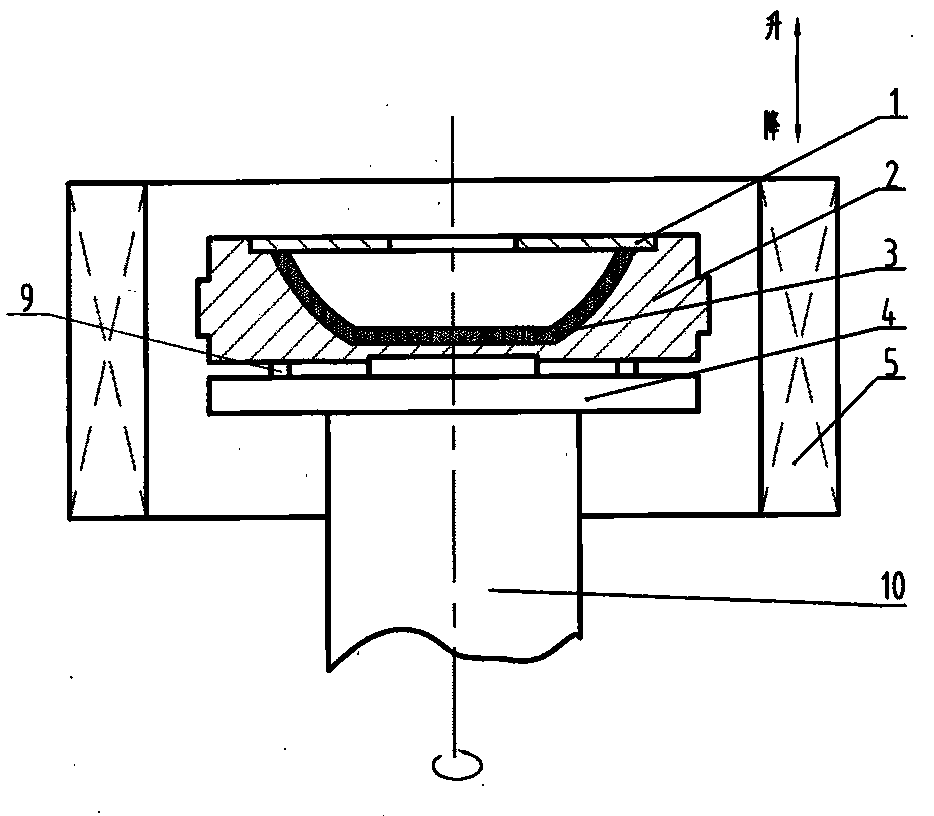

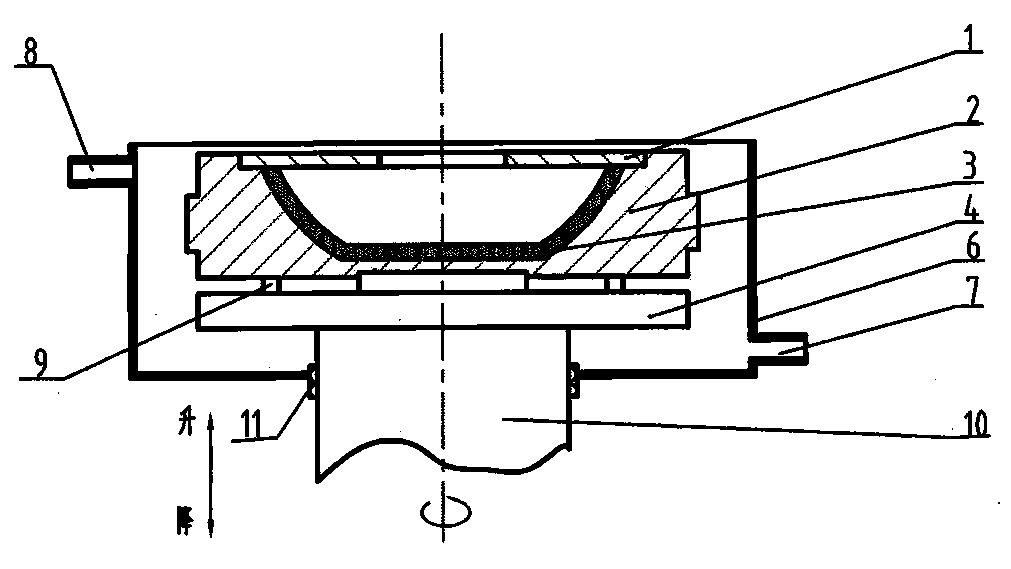

[0070] Please refer to the attached figure 2 with image 3 . The outline size of the lower cover of the spherical bearing seat: such as Figure 5 Shown. According to the outline size, make a steel shell of corresponding size and shape;

[0071] a) Ingredients: 6Kg copper alloy particles (a mixture with a particle size of 1.0~1.6mm) and 400g copper gas flux are mixed, and the surface of the above mixture is covered with 30g wood carbon powder.

[0072] b) Casting process: 1) Lower and move into the electric induction heater 5; 2) Use 60Kw power to heat for 2min at a speed of 200r / min; 3) Adjust the power to 80Kw and heat for 46min; 4) Adjust the power to 50Kw and heat for 4.5min 5) Adjust the power to 0Kw and remove the electric induction heating device 5 for air cooling for 3 minutes; 6) The cooling water tank 6 of the rising water cooling device is water cooled for 14 minutes. There is a φ90mm vent hole in the center of the cover plate 1, and the concentricity of the correction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentricity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com