Hard rock bypass crushing system of autogenous mill

A crushing system and autogenous mill technology, applied in grain processing and other directions, can solve the problems of low operation rate, large crushing workshop and high civil construction investment, and achieve the effect of improving recovery rate and ensuring processing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

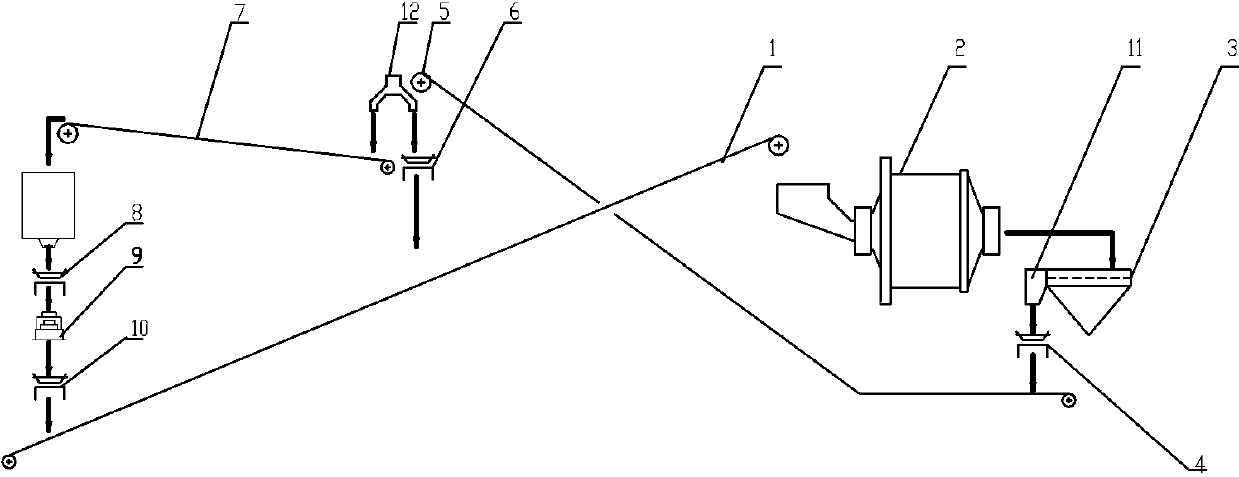

[0010] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

[0011] Such as figure 1 As shown, the self-grinding machine stubborn stone bypass crushing system of the present invention comprises a self-grinding machine feeding belt conveyor 1 and an self-grinding machine 2, and is characterized in that a double-layer vibrating screen is arranged under the self-grinding machine 2 ore discharge funnels 3. On the side of the upper sieve of the double-layer vibrating screen, there is a boulder chute 11 and a boulder bypass crushing system. The boulder bypass crushing system includes a belt conveyor for boulder discharge on the screen connected in sequence 4 , stubborn stone transfer belt conveyor 5, stubborn stone bypass belt conveyor 6, stubborn stone crushing feeding bin feeding belt conveyor 7, stubborn stone crusher feeding belt conveyor 8, stubborn stone crusher 9 and a broken product belt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com