Magnetic meso-porous silicon, preparation method of magnetic meso-porous silicon, magnetic meso-porous silicon adsorbent, preparation method and application of magnetic meso-porous silicon adsorbent

A mesoporous silicon and adsorbent technology, applied in the field of magnetic mesoporous silicon, preparation, magnetic mesoporous silicon adsorbent, can solve the problems of surfactant and transfer agent toxicity, uneven magnetic distribution, long preparation time, etc. The effect of reducing diffusion resistance, uniform magnetic distribution, and stable physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

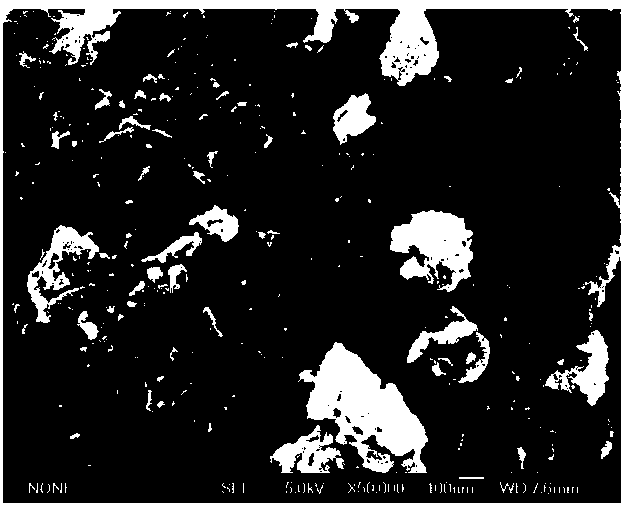

[0032] Preparation method of magnetic mesoporous silicon

[0033] 1. Synthesis of mesoporous composites

[0034] Preparation by soft template method: prepare 200mL of 0.1mol / L hydrochloric acid solution, add 4g of F-127 block copolymer (purchased from sigma-Aldrich) to it, and stir mechanically; add 35.2g of ferrous ammonium sulfate, and stir until dissolved ; Then add 18.6g ethyl orthosilicate. Stir mechanically for 8 hours in an ice-water bath to obtain a clear solution; add the above mixed solution into a digestion tank, and conduct a hydrothermal reaction at 100° C. for 24 hours; collect solid matter by centrifugation.

[0035] 2. Preparation of magnetic mesoporous silicon

[0036] Under the condition of 60°C water bath, the above mesoporous composite was immersed in 300mL of sodium hydroxide solution with a concentration of 0.1mol / L, and 350μL of hydrogen peroxide solution with a mass concentration of 30% was added to oxidize ferrous iron into tetraoxide Three irons, g...

Embodiment 2

[0042] Removal of hexavalent chromium from water by magnetic mesoporous silica adsorbent

[0043] Add 8 mg of magnetic mesoporous silicon adsorbent to 10 ml of a solution containing hexavalent chromium with a concentration of 100 mg / L, adjust the pH to 2, shake at room temperature at 150 rpm for 410 min, and the removal rate of hexavalent chromium is 92%. Then, the above-mentioned magnetic mesoporous silicon adsorbent adsorbed with hexavalent chromium was added to a sodium hydroxide solution with a concentration of 0.01 mol / L, desorbed by shaking for 3 hours, centrifuged, and washed until neutral to obtain a magnetic mesoporous silicon adsorbent. The polyaniline grafted on the magnetic mesoporous silicon adsorbent can reduce hexavalent chromium to trivalent chromium, and since the toxicity of trivalent chromium is obviously lower than that of hexavalent chromium, the toxicity of pollutants can be reduced.

Embodiment 3

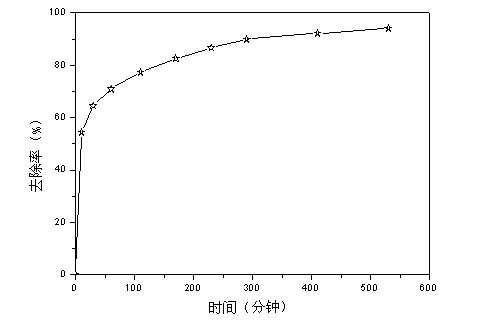

[0045] Removal rate of hexavalent chromium by magnetic mesoporous silica adsorbent under different conditions

[0046] Removal rate of hexavalent chromium by magnetic mesoporous silicon adsorbent under different adsorption time conditions

[0047] Set up nine groups containing 0.008g magnetic mesoporous silicon adsorbent and 10mL hexavalent chromium solution with a concentration of 100mg / L, adjust the pH value to 2, and oscillate at room temperature at 150rmp. , 410, 530min sampling, after centrifugation, use ultraviolet spectrophotometry to measure the content of hexavalent chromium in the supernatant, and calculate the removal rate. Experimental results such as image 3 As shown, under this condition, the equilibrium time for magnetic mesoporous silicon adsorbent to adsorb hexavalent chromium is 410min.

[0048] Removal rate of hexavalent chromium by magnetic mesoporous silica adsorbent under different solution pH values

[0049] Ten groups containing 0.008g magnetic meso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com