Bend-type outgoing line high-voltage shielding electric connector plug

An electrical connector, high-voltage technology, applied in the direction of connection, the device for reducing the stress at the connection of the wire, the parts of the connection device, etc. Improve connection reliability, ensure location, and reduce volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

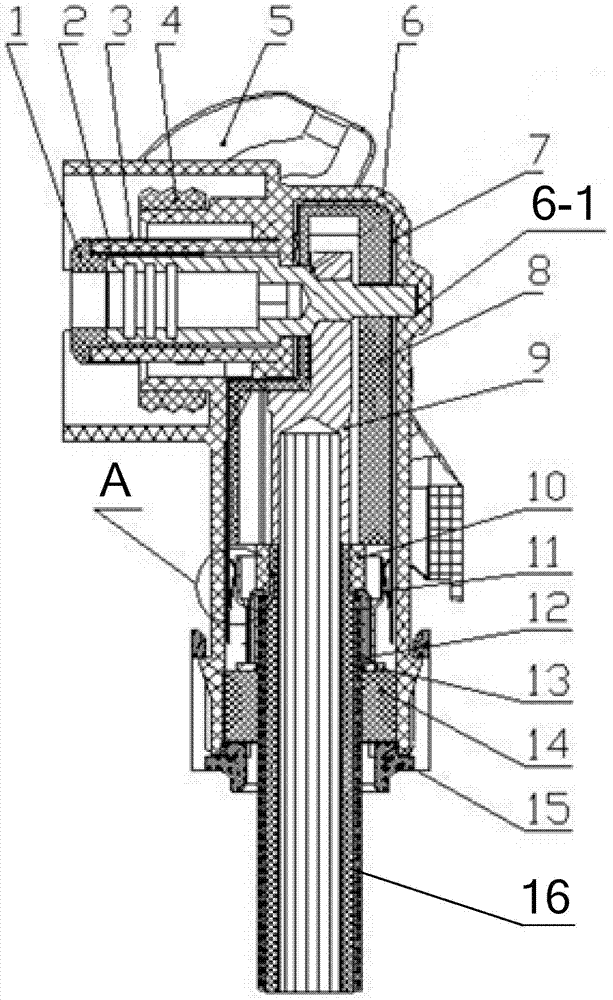

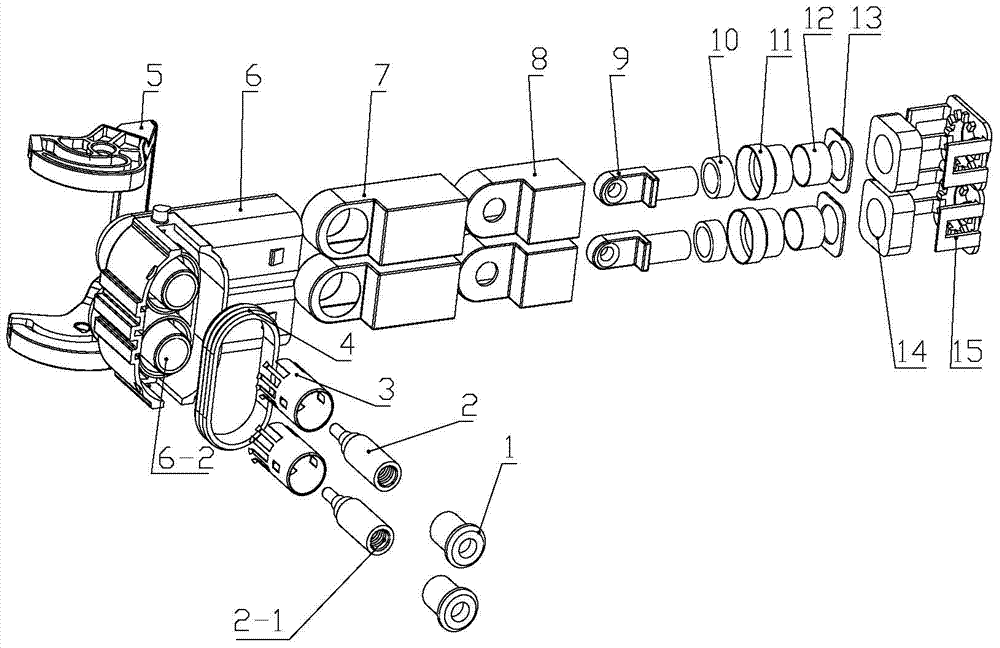

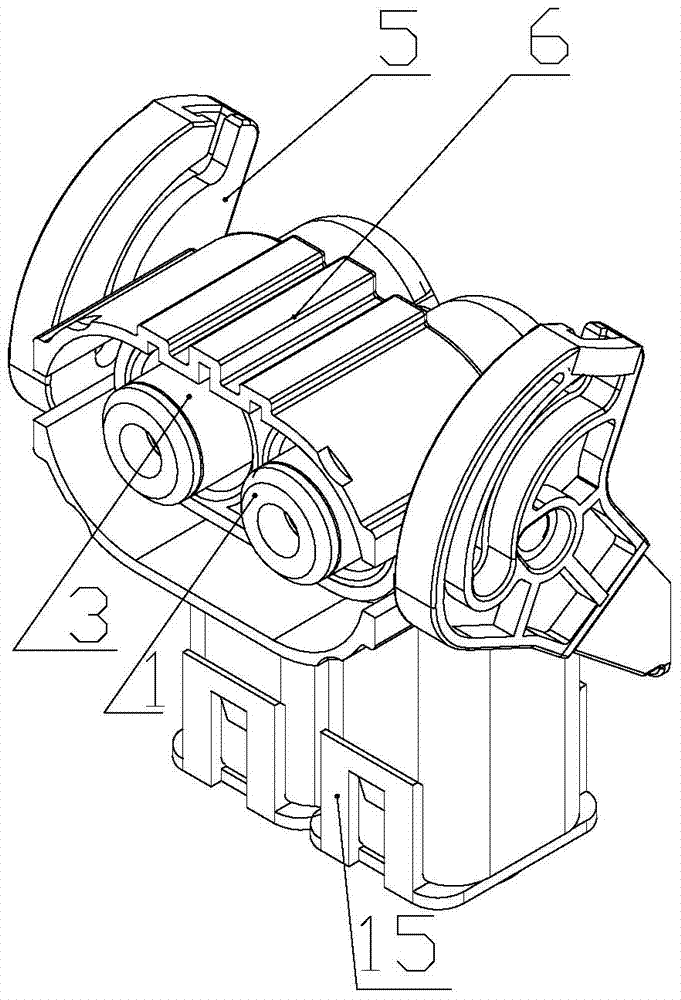

[0025] Such as figure 1 , 2 As shown in 3 and 3, a plug for an angled outlet high-voltage shielded electrical connector includes a plug housing 6, an adapter assembly, a wiring assembly, and a mating assembly. The plug housing 6 includes an integrally formed outlet part and a mating part, and the outlet part and the interior of the mating part are set through; the outlet part is provided with two transfer shielding installation grooves 6-1; the top of the mating part is provided with a sealing ring 4 , the outer wall is provided with a locking handle 5, and the inside is provided with two insertion post positioning holes 6-2 and two insertion shielding assembly holes 6-3, the insertion post positioning holes 6-2 and the corresponding insertion shielding assembly holes 6 -3 are arranged coaxially; the mating shield assembly hole 6-3 and the transition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com