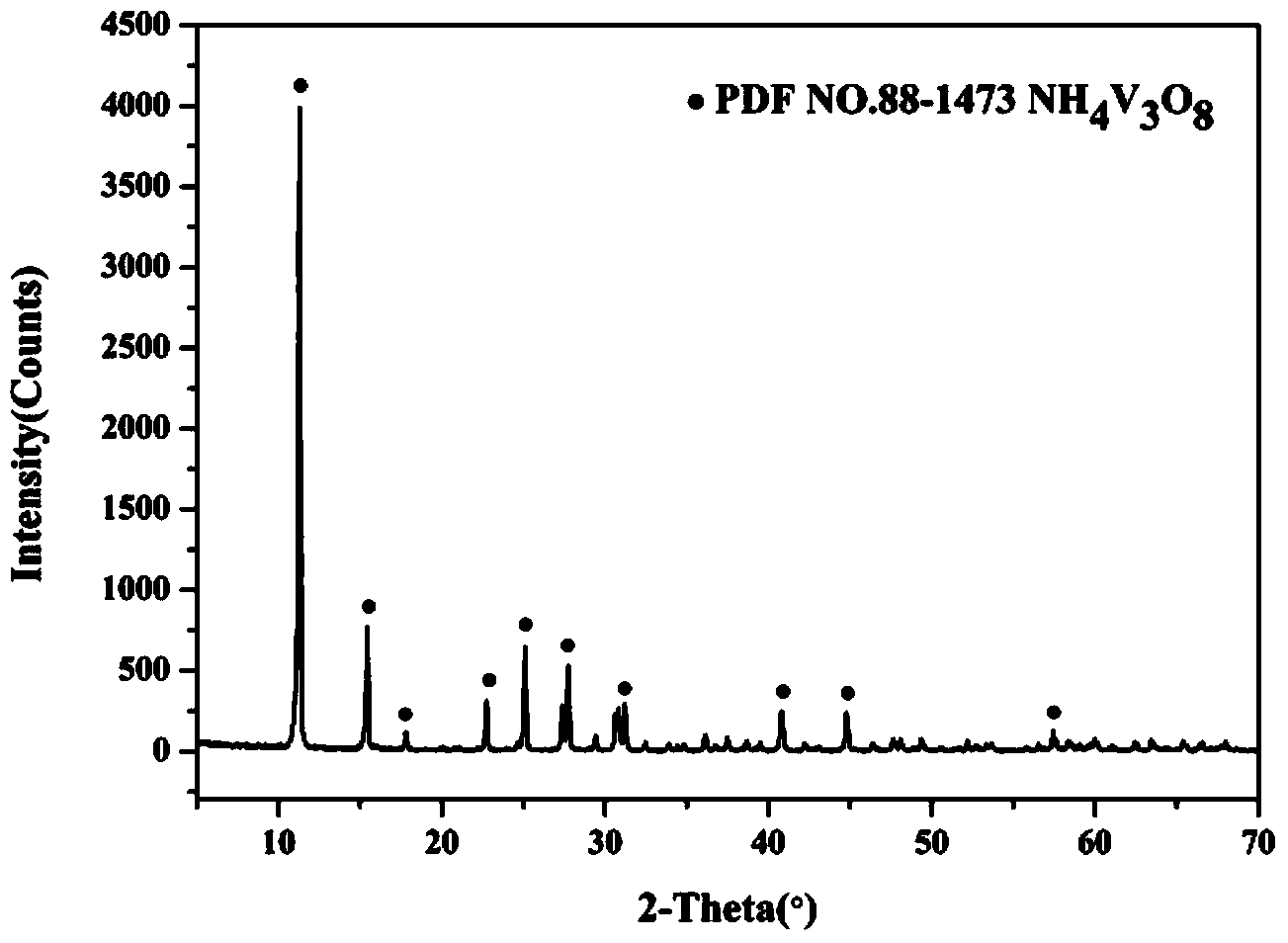

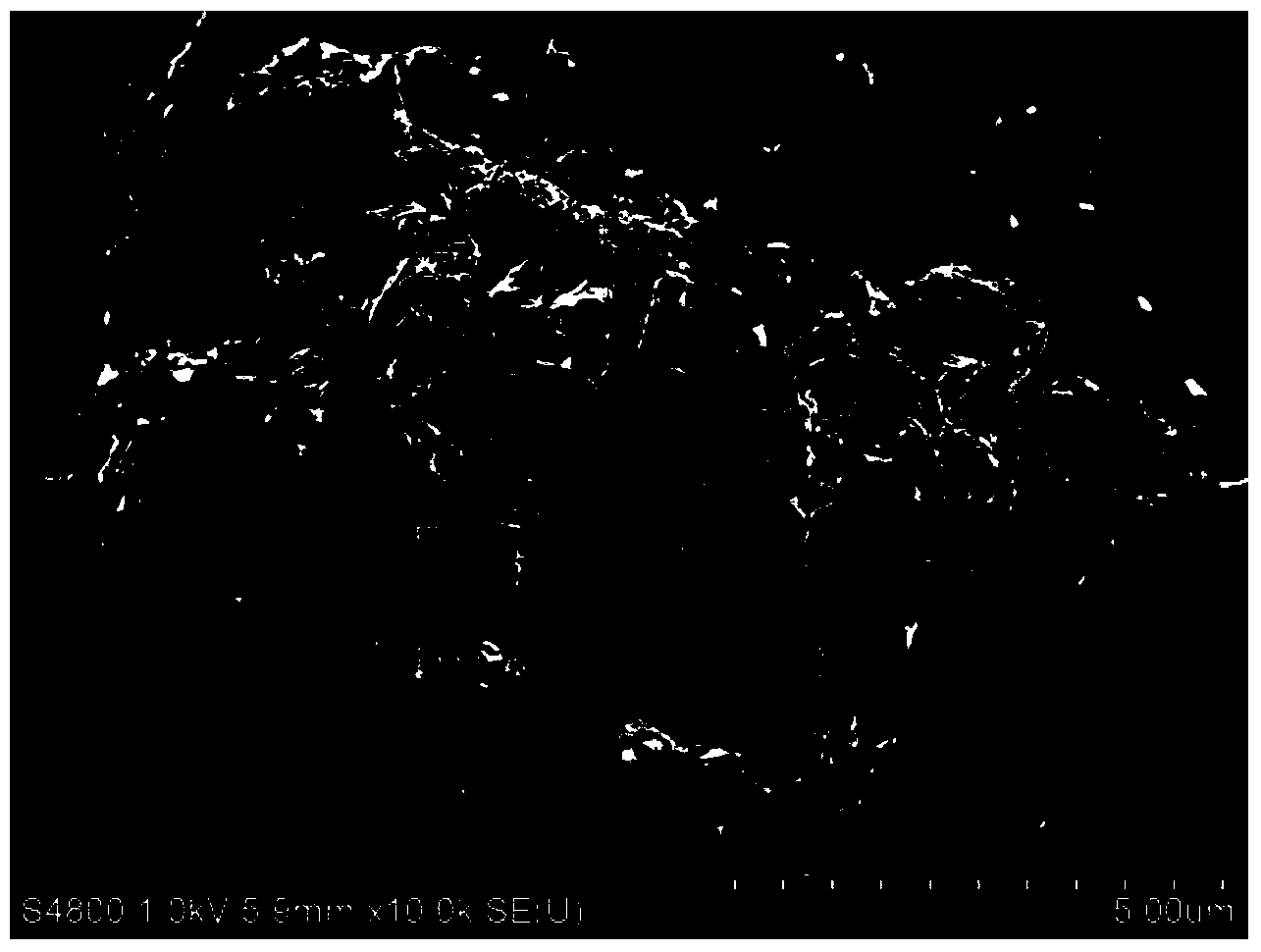

Preparation method of porous structure ammonium vanadate material

A porous structure, ammonium vanadate technology, applied in structural parts, vanadium oxide, electrical components, etc., can solve the problems of difficult control of the reaction process, occurrence of side reactions, high reaction temperature, etc., and achieve good electrochemical performance and short reaction time , the effect of low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) The analytically pure ammonium metavanadate (NH 4 VO 3 ) was dissolved in deionized water at 60°C, and magnetically stirred for 1 hour to dissolve the ammonium metavanadate evenly to obtain NH 4 + The concentration is 0.10mol / L of NH 4 VO 3 Solution, denoted as A solution;

[0027] 2) Use 5mol L -1 dilute hydrochloric acid to adjust the pH value of the A solution to 1.5, and then carry out the sonochemical reaction of the A solution after adjusting the pH value under the ultrasonic power of 400W for 1 hour to obtain the B solution;

[0028] 3) Pour the B solution into the reactor, let the microwave and the ultraviolet lamp act on the B solution at the same time, wherein the wavelength of the ultraviolet lamp is 365nm, the power of the ultraviolet lamp is 500W, and the microwave power is controlled at 400-600W, and the platinum resistance is used for temperature measurement , after raising the temperature from room temperature to 90 °C at a heating rate of 15 °C...

Embodiment 2

[0032] 1) The analytically pure ammonium metavanadate (NH 4 VO 3 ) was dissolved in deionized water at 60°C, and magnetically stirred for 1 hour to dissolve the ammonium metavanadate evenly to obtain NH 4 + The concentration is 0.08mol / L of NH 4 VO 3 Solution, denoted as A solution;

[0033] 2) Use 4mol·L -1 dilute hydrochloric acid to adjust the pH value of the A solution to 2.0, and then perform a sonochemical reaction under 400W ultrasonic power for 0.5h to obtain the B solution;

[0034] 3) Pour the B solution into the reactor, and let the microwave and the ultraviolet lamp act on the solution at the same time, wherein the wavelength of the ultraviolet lamp is 365nm, the power of the ultraviolet lamp is 500W, and the microwave power is controlled at 400-600W, and the platinum resistance is used for temperature measurement. After raising the temperature from room temperature to 80 °C at a heating rate of 15 °C / min, keep it warm for 30 min, and then naturally cool to r...

Embodiment 3

[0037] 1) The analytically pure ammonium metavanadate (NH 4 VO 3 ) was dissolved in deionized water at 55°C, stirred magnetically for 0.75h to dissolve ammonium metavanadate evenly, and NH 4 + The concentration is 0.06mol / L of NH 4 VO 3 Solution, denoted as A solution;

[0038] 2) Use 3mol L -1 dilute hydrochloric acid to adjust the pH value of the A solution to 2.50, and then perform a sonochemical reaction under 300W ultrasonic power for 0.5h to obtain the B solution;

[0039] 3) Pour the B solution into the reactor, and let the microwave and the ultraviolet lamp act on the solution at the same time, wherein the wavelength of the ultraviolet lamp is 365nm, the power of the ultraviolet lamp is 500W, and the microwave power is controlled at 400-600W, and the platinum resistance is used for temperature measurement. After raising the temperature from room temperature to 70 °C at a heating rate of 15 °C / min, keep it warm for 40 min, and then cool it down to room temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com