Semi-material dyeing technology of silk-cotton interweaving garment material

A silk-cotton and clothing technology, applied in the field of half-material dyeing process of silk-cotton interwoven clothing fabrics, can solve the problems of unable to meet the performance requirements of silk-cotton interwoven clothing fabrics, the color of silk-cotton interwoven fabrics is not bright enough, time-consuming and labor-intensive, etc., to achieve The dyeing process and color control are simple and easy, the visual effect has no sense of white fog, and the effect of reducing waste water discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

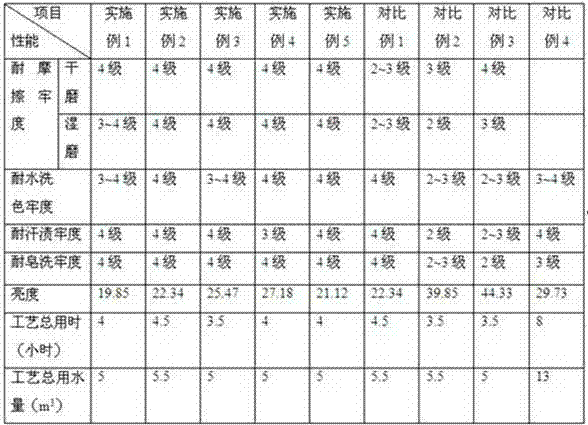

[0029] Embodiment 1 is the best embodiment of the present invention, and the present invention will be further described below. Wherein, embodiment 1~5 and comparative example 1~4 used silk-cotton interweaving garment fabric textures are identical, quality is equal, and warp thread is real silk fiber, and weft thread is cotton fiber, and the silk-cotton interweaving garment fabric total mass used is 100 kilograms.

[0030] The Everzol reactive dyes used in Examples 1 to 5 and Comparative Examples 1 to 4 are Everzol reactive dyes produced by Taiwan Yongguang Chemical Industry Co., Ltd. Everzol ED reactive dye is the Everglow Everzol ED reactive dye produced by Taiwan Yongguang Chemical Industry Co., Ltd. B-type reactive dyes are B-type reactive dyes produced by Zhejiang Longsheng Group Co., Ltd. The anionic surfactant is a phosphate ester salt type anionic surfactant produced by Qingdao Yinrui Chemical Co., Ltd. Sodium sulfate is Yuanming powder, and sodium carbonate is soda ...

Embodiment 2

[0042] In the present embodiment, the silk-cotton interweaving clothing fabric is dyed into navy blue, and its method is as follows:

[0043] The formula ratio of the dyeing agent: Everzol reactive dye black B3.75%owf, B-type reactive dye blue B-2GLN0.5%ow, anionic surfactant is 3g / L alkylphenol polyoxyethylene ether phosphate , sodium sulfate 100g / L, sodium carbonate 2g / L mixed with water to prepare the first dyeing agent; B-type reactive dye blue B-2GLN0.5%owf, Everzol ED dye reactive black ED-G3.25%owf mixed with water Mix, prepare the second staining agent; The B-type reactive dye in the first staining agent and the second staining agent is equal to the added quality of reactive blue B-2GLN;

[0044] 1) Pre-treatment of silk and cotton interwoven clothing fabrics;

[0045] 2) Dyeing and color fixation: the total dyeing time is 60 minutes. Pre-treat the silk-cotton interwoven garment fabric, put the pre-treated silk-cotton interwoven garment fabric into the prepared first ...

Embodiment 3

[0052] In the present embodiment, the silk-cotton interweaving clothing fabric is dyed into navy blue, and its method is as follows:

[0053] The formula ratio of the dyeing agent: Everzol reactive dye reactive red 3BS2%owf, B-type reactive blue B-2GLN1.5%owf, anionic surfactant is 3g / L lauryl ether phosphate potassium salt, sulfuric acid Mix sodium 85g / L, sodium carbonate 3g / L with water to prepare the first dyeing agent; mix B-type reactive blue B-2GLN1.5%owf, Everzol ED dye reactive black ED-G3%owf with water to prepare the second Staining agent; the B-type reactive dye in the first staining agent and the second staining agent is equal to the added quality of reactive blue B-2GLN;

[0054] 1) Pre-treatment of silk and cotton interwoven clothing fabrics;

[0055] 2) Dyeing and color fixation: the total dyeing time is 100 minutes. Pre-treat the silk-cotton interwoven garment fabric, put the pre-treated silk-cotton interwoven garment fabric into the prepared first dyeing agen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com