Auxiliary device used for perfecting online dynamic annealing of long baseband for coated conductor and implementation method

A technology of auxiliary devices and coated conductors, applied in furnaces, heat treatment equipment, heat treatment furnaces, etc., can solve the problems of large energy consumption, protective atmosphere, low production efficiency, etc., to save energy and protective atmosphere consumption, simple structure, The effect of reducing production costs and labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

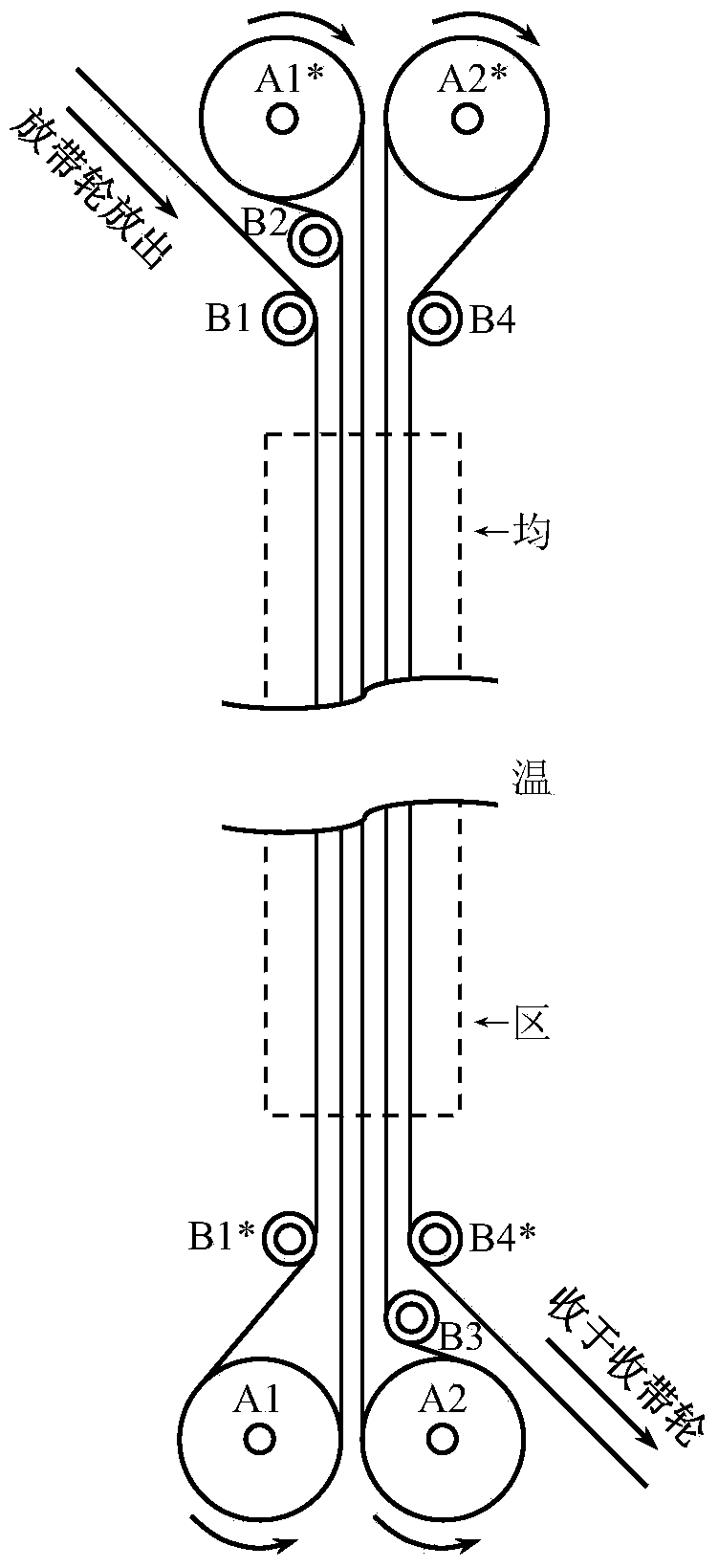

[0020] Such as figure 1 As shown, a group of steering devices A1 and A1* and guide devices B1 and B1*, B2 and B2* of the present invention are installed on both sides of the opening outside the uniform temperature zone of the furnace according to the design requirements to ensure that the Ni-5at.% to be annealed The long base tapes of W alloy do not touch each other during tape running.

[0021] In order to achieve a comparative effect, this embodiment still uses the parameters of the case in the background technology, that is, the length of the uniform temperature zone is 0.9m, and the dynamic annealing of the 100m-long baseband is completed, and the process parameters are 1100°C for 3 hours. Due to the use of a set of steering devices, it is equivalent to the three-thread online dynamic annealing of the long base belt at the same time, so the belt running speed is 0.9m / h, that is, it takes 1 hour to enter and exit the uniform temperature zone once, and a total of 3 times to ...

Embodiment 2

[0024] Such as figure 2 As shown, the two sets of steering devices A1 and A1*, A2 and A2* and guide devices B1 and B1*, B2, B3, B4 and B4* of the present invention are installed on both sides of the opening outside the uniform temperature zone of the furnace according to the design requirements. It is ensured that the long base bands of the Ni-5at.%W alloy to be annealed do not contact each other during the band travel.

[0025] Similar to Embodiment 1, this embodiment still adopts various parameters of the case in the background technology to achieve a comparative effect. Due to the use of two sets of steering devices, it is equivalent to five threads of the long baseband being dynamically annealed online at the same time, and the tape running speed is 1.5m / h, that is, it takes 0.6h to enter and exit the uniform temperature zone once, and a total of 5 times to enter and exit can reach The process requirement of heat preservation for 3h. Still ignoring the heating and cooli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com