A kind of high and low temperature resistant siloxane vacuum grease composition and its preparation method

A lubricating grease composition, high and low temperature resistance technology, applied in the direction of lubricating composition, petroleum industry, thickener, etc., can solve the problems of storage and vacuum sealing performance reduction, unexplained silica powder, etc., to achieve improved compatibility properties, excellent long-term storage stability, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

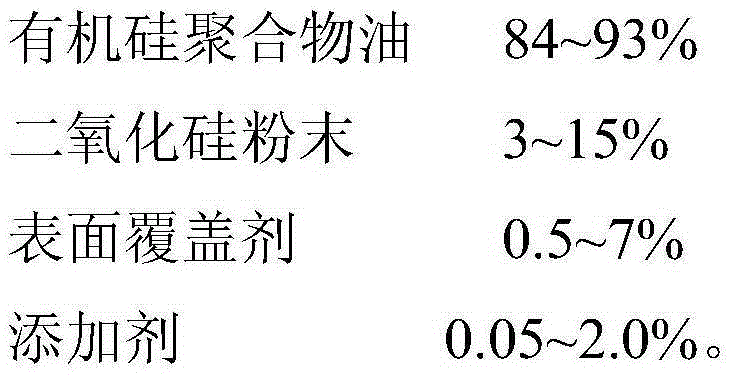

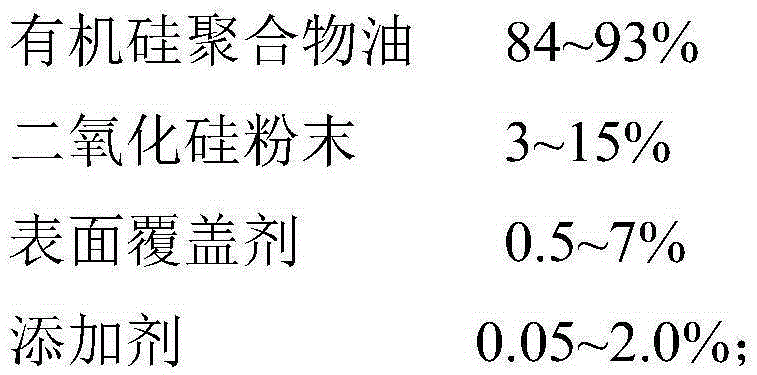

Method used

Image

Examples

Embodiment 1

[0035] Put 135Kg of trimethyl-terminated polymethylphenylsiloxane oil into the equipment container, heat and stir, and when the temperature is at 120°C, add 14.25Kg of silicon dioxide powder that has been modified by a surface covering agent, Stir and mix continuously for 2 hours, then cool, grind twice, then add 0.75Kg of functional additives, mix for 0.5h, go through vacuum degassing treatment, and finally grind twice again to get the grease. The consistency of the grease was measured after storage for 12 months and a change of 0.8% was determined, demonstrating the long-term stability of the grease.

Embodiment 2

[0037] Put 136.5Kg of trimethyl-capped polydimethylsiloxane oil into the equipment container, heat and stir, and when the temperature is at 130°C, add 12.3Kg of silica powder modified by a surface covering agent, Stir and mix continuously for 3 hours, then cool, grind twice, then add 1.2Kg of functional additives, mix for 1 hour, go through vacuum degassing treatment, and finally grind twice again to get the grease. The consistency of the grease was measured after storage for 12 months and a 1.0% change was determined, demonstrating the long-term stability of the grease.

Embodiment 3

[0039] Put 142.4Kg of silanol-terminated polydimethylsiloxane oil into the equipment container, heat and stir, and when the temperature is at 140°C, add 14.4Kg of silicon dioxide powder that has been modified by a surface covering agent, continuously Stir and mix for 1.5 hours, then cool, grind twice, then add 3.2Kg of functional additives, mix for 0.5 hours, then undergo vacuum degassing, and finally grind twice again to obtain the grease. The consistency of the grease was measured after storage for 12 months and a change of -0.9% was determined, which proves the long-term stability of the grease.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com