Method for fast producing methane by utilizing excess sludge

A technology for excess sludge and methane production, which is applied in the field of water treatment, can solve the problems of low gas production, large investment, and unstable gas production in anaerobic digestion of excess sludge, and is beneficial to engineering applications, small in size, and economical The effect of potion consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

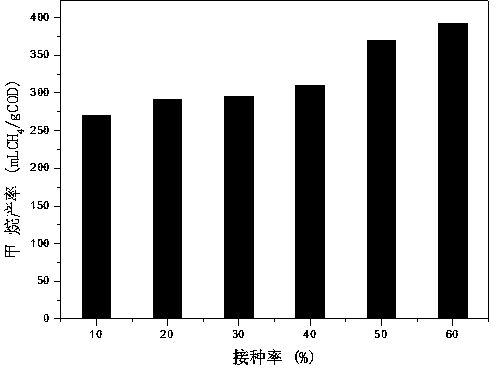

Image

Examples

Embodiment 1

[0041] (1) Single-stage alkaline hydrolysis operation process: Inject X volume of pretreated excess sludge into the reactor, while stirring at 150 rpm, add alkali to adjust the pH to 13.0 with 10 M sodium hydroxide solution, and stir to react 1h, the organic matter in the sludge is released to the water phase to the maximum extent, and the liquefaction of the organic matter is realized, which is alkaline hydrolysis sludge. Depend on figure 2 It can be seen that in the range of pH 10.0-13.5, as the pH increases, SCOD continues to increase, indicating that more organic matter is released into the water phase, and the effect is very significant; but considering that SCOD increases slowly after pH 13.0, and the required The amount of sodium hydroxide added increased sharply, and the more suitable pH condition was selected as 13.0.

[0042] (2) Inject 2.5X volume of pretreated residual sludge directly into the alkaline hydrolysis sludge and mix, continue to stir and react for 1 h...

Embodiment 2

[0047] (1) The operation process of secondary alkaline hydrolysis is as follows: figure 1 As shown, in the first-stage alkaline hydrolysis reactor A, inject X volume of pretreated excess sludge 1, stir at 150 rpm, and perform alkaline hydrolysis reaction for 1 hour to control the pH at about 8.5. Then centrifuge to discharge the supernatant, that is, the first-stage alkaline hydrolysis effluent 6, and discharge the system; the residue after centrifugation, that is, the first-stage alkaline hydrolysis residue 2, is injected into the second-stage alkaline hydrolysis reactor. In the second-stage alkaline hydrolysis reactor B, inject 2 / 7X volume of water, adjust the pH to 13.0 with 10M sodium hydroxide solution while stirring at 150rpm, and continue the alkaline hydrolysis reaction for 1 hour, so that the organic matter can be released to the water to the greatest extent phase to realize the liquefaction of organic matter in excess sludge. Then centrifuge to obtain the supernata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com