Tungsten trioxide nano-film with photocatalytic performance, and preparation method thereof

A technology of tungsten trioxide and nano-thin films, applied in chemical instruments and methods, tungsten oxide/tungsten hydroxide, nanotechnology for materials and surface science, etc., can solve the unfavorable separation of photogenerated electrons and holes, and accept light Insufficient area, insufficient specific surface area, etc., to alleviate the shortage of fossil fuels, increase the specific surface area, and improve the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

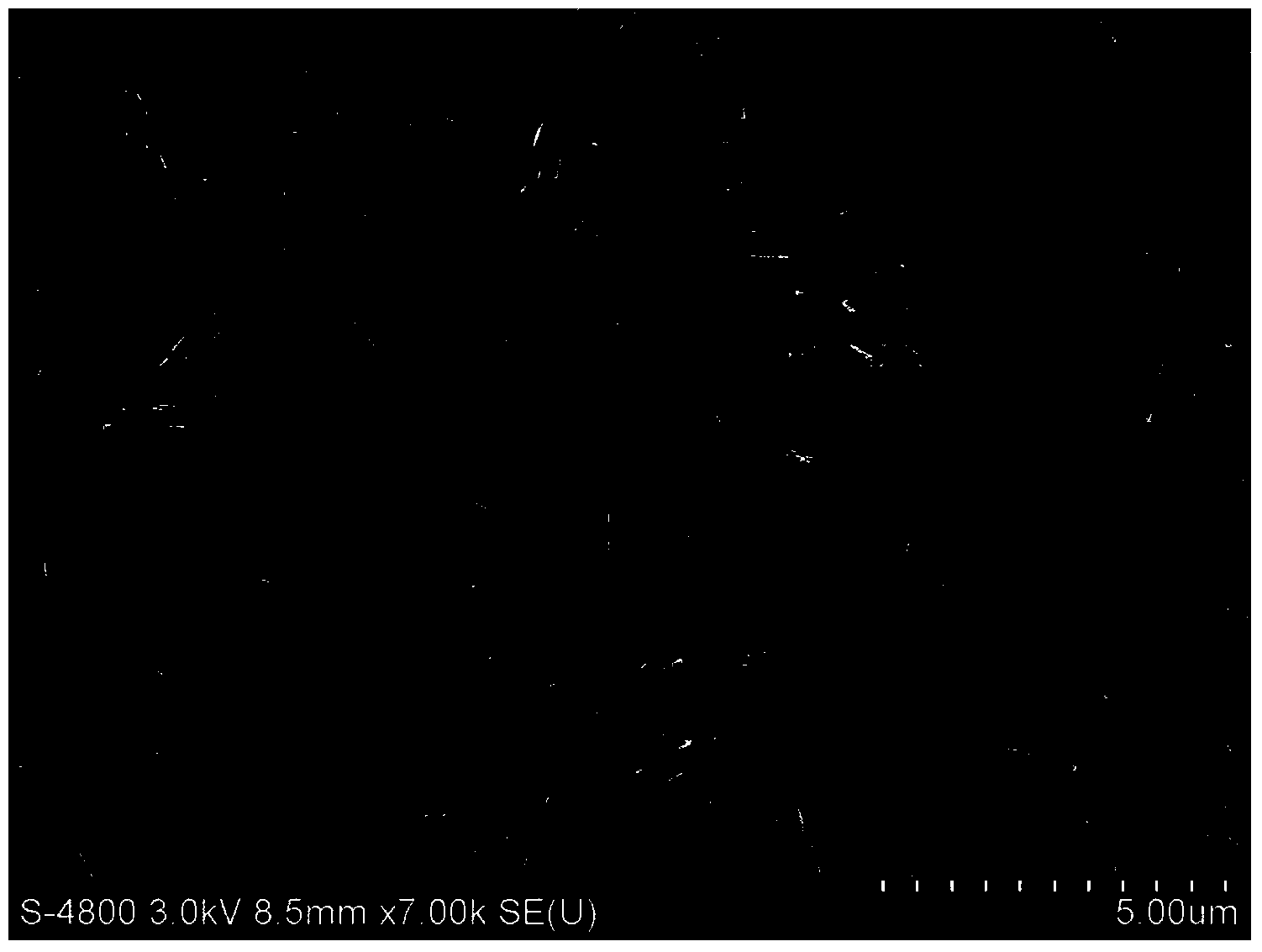

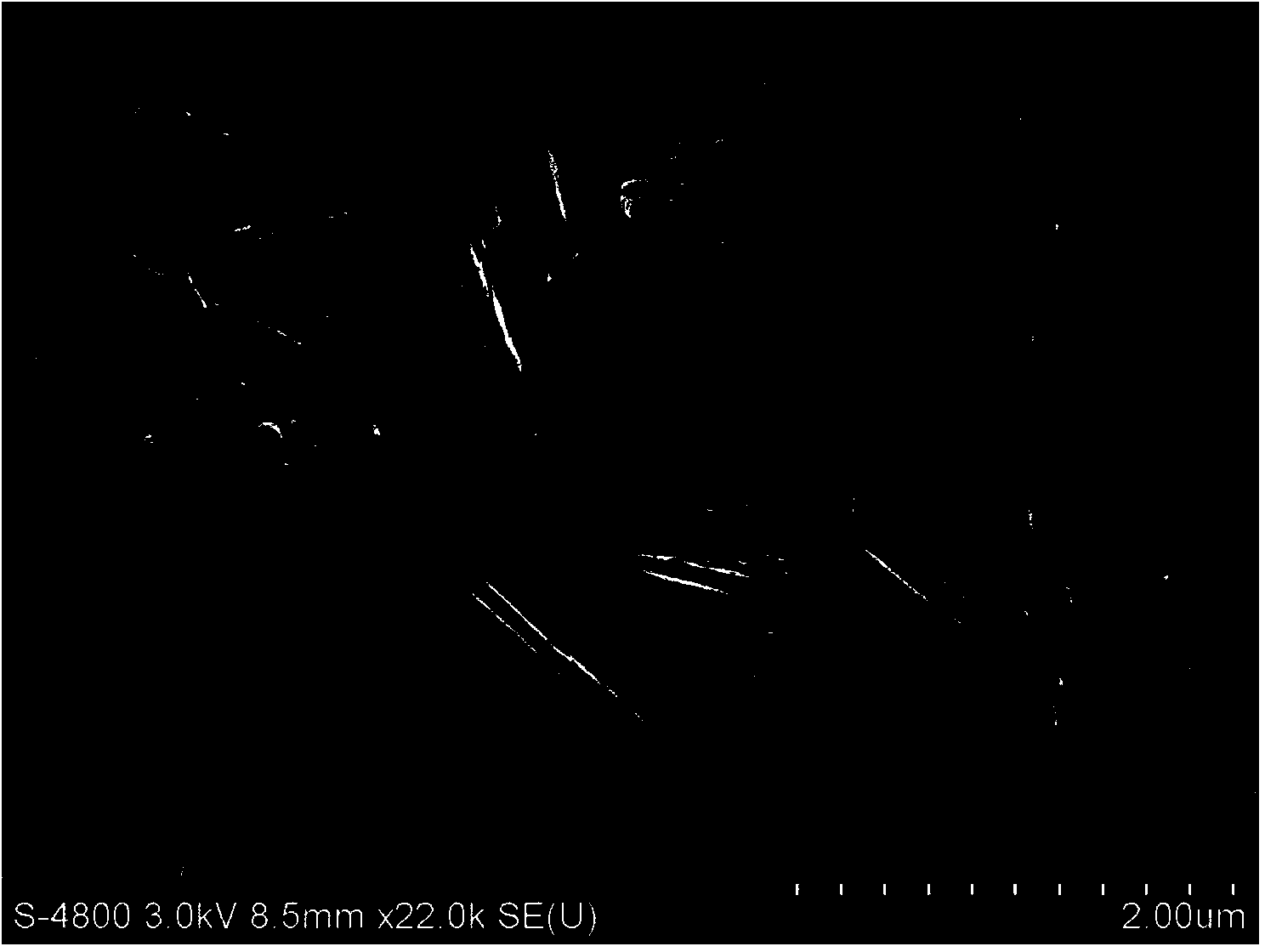

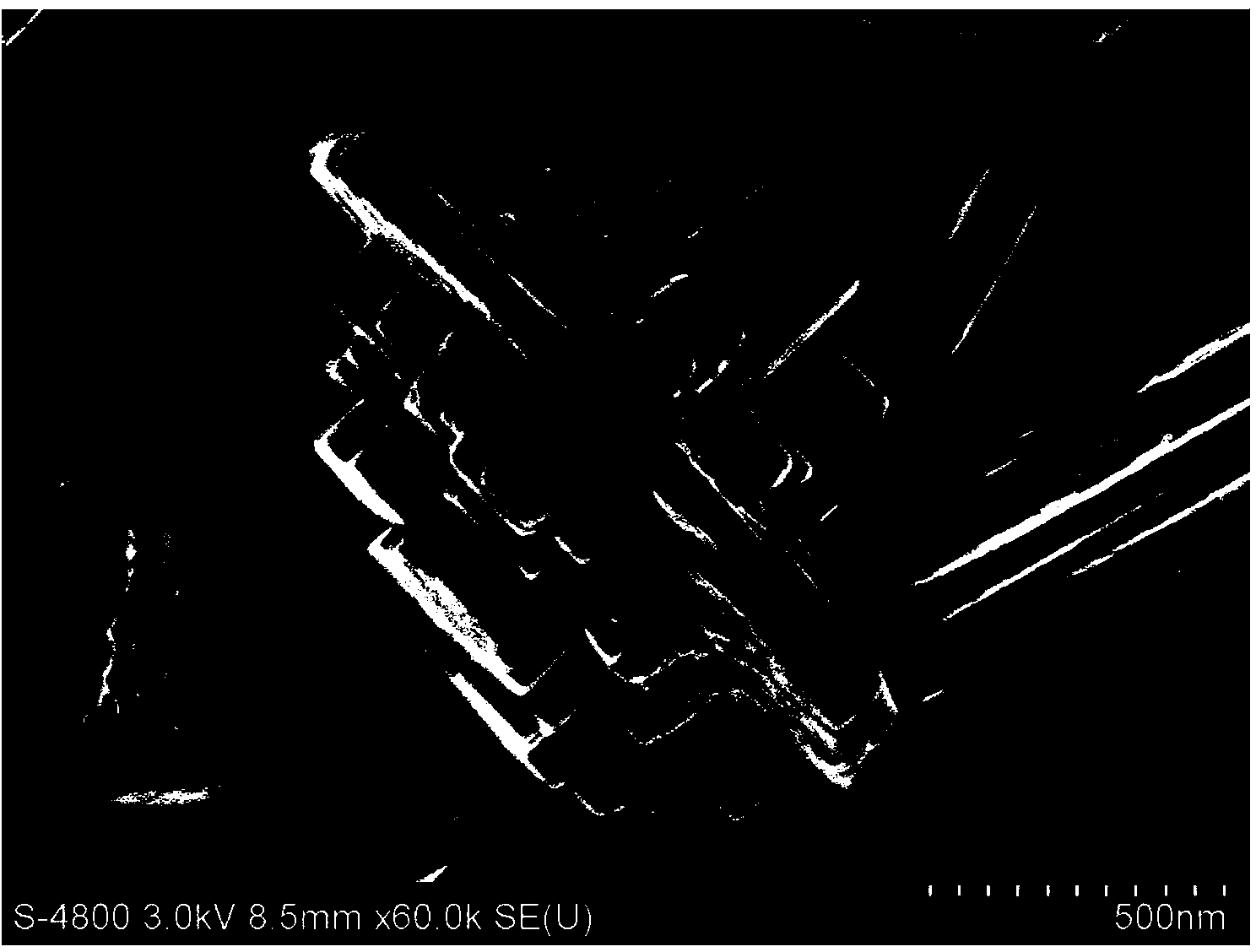

Image

Examples

Embodiment 1

[0042] (1) WO 3 Preparation of seed coating

[0043] ① Sonicate the FTO conductive glass in deionized water, acetone and ethanol solution for 10 minutes successively, wash it with deionized water, and dry it for later use;

[0044] ②Preparation of tungstic acid seed layer precursor solution: first mix 1.25g tungstic acid powder, 0.5g polyvinyl alcohol, and 20mL hydrogen peroxide (volume concentration: 30%), and stir at 80°C for 1 hour to obtain 0.25mol / The tungstic acid seed layer precursor solution of L;

[0045] ③Using the method of spin coating, the precursor solution of the tungstic acid seed layer is dynamically coated on the conductive surface of the FTO conductive glass. The conditions of the spin coater are: 500 rpm, spin for 3 minutes;

[0046] ④The FTO conductive glass coated with the precursor solution of tungstic acid seed layer is roasted, using a muffle furnace, the conditions are: heating rate 2°C / min, heating up to 500°C, keeping it for 2 hours, and cooling...

Embodiment 2

[0066] (1) WO 3 The preparation of the seed coating was the same as in Example 1.

[0067] (2) WO 3 Preparation of nanocoating

[0068] ① Prepare the solvothermal precursor solution of tungstic acid: first mix 1g of tungstic acid powder, 10mL of hydrogen peroxide (volume concentration: 30%), and 30mL of deionized water, and stir at 92°C for 1 hour to obtain a preliminary tungstic acid precursor solution. Transfer it into a 100mL volumetric flask, and dilute to volume with deionized water to prepare a 0.04moL / L tungstic acid solution as the final tungstic acid solvothermal precursor solution.

[0069] ② Preparation of crystallization kettle solution: Take 3mL tungstic acid solvothermal precursor solution, mix with 2.5mL deionized water, 0.5mL hydrochloric acid (mass concentration: 37.5%), and 10mL ethylene glycol, and stir for 15 minutes to make it evenly mixed.

[0070] ③ Place the prepared FTO conductive glass with the seed layer facing upwards in the crystallization kett...

Embodiment 3

[0076] (1) WO 3 The preparation of the seed coating was the same as in Example 1.

[0077] (2) WO 3 Preparation of nanocoating

[0078] ① Prepare the solvothermal precursor solution of tungstic acid: first mix 1.5g tungstic acid powder, 10mL hydrogen peroxide (volume concentration: 30%), and 30mL deionized water, and stir at 92°C for 1 hour to obtain a preliminary tungstic acid precursor body solution. Transfer it into a 100mL volumetric flask, and make up to volume with deionized water to prepare a 0.06moL / L tungstic acid solution as the final tungstic acid solvothermal precursor solution.

[0079] ② Preparation of crystallization kettle solution: Take 3mL tungstic acid solvothermal precursor solution, mix with 2.5mL deionized water, 0.5mL hydrochloric acid (mass concentration: 37.5%), and 10mL ethylene glycol, and stir for 15 minutes to make it evenly mixed.

[0080] ③ Place the prepared FTO conductive glass with the seed layer facing upwards in the crystallization kettl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Photocurrent density | aaaaa | aaaaa |

| Photocurrent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com