Red mud adsorbent for removing organic dye pollutants, and preparation method of adsorbent

A technology of organic dyes and pollutants, applied in water pollutants, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problems of deteriorating ecological environment, air pollution, soil pollution, etc., and achieve pollution problems with low cost , the effect of high adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

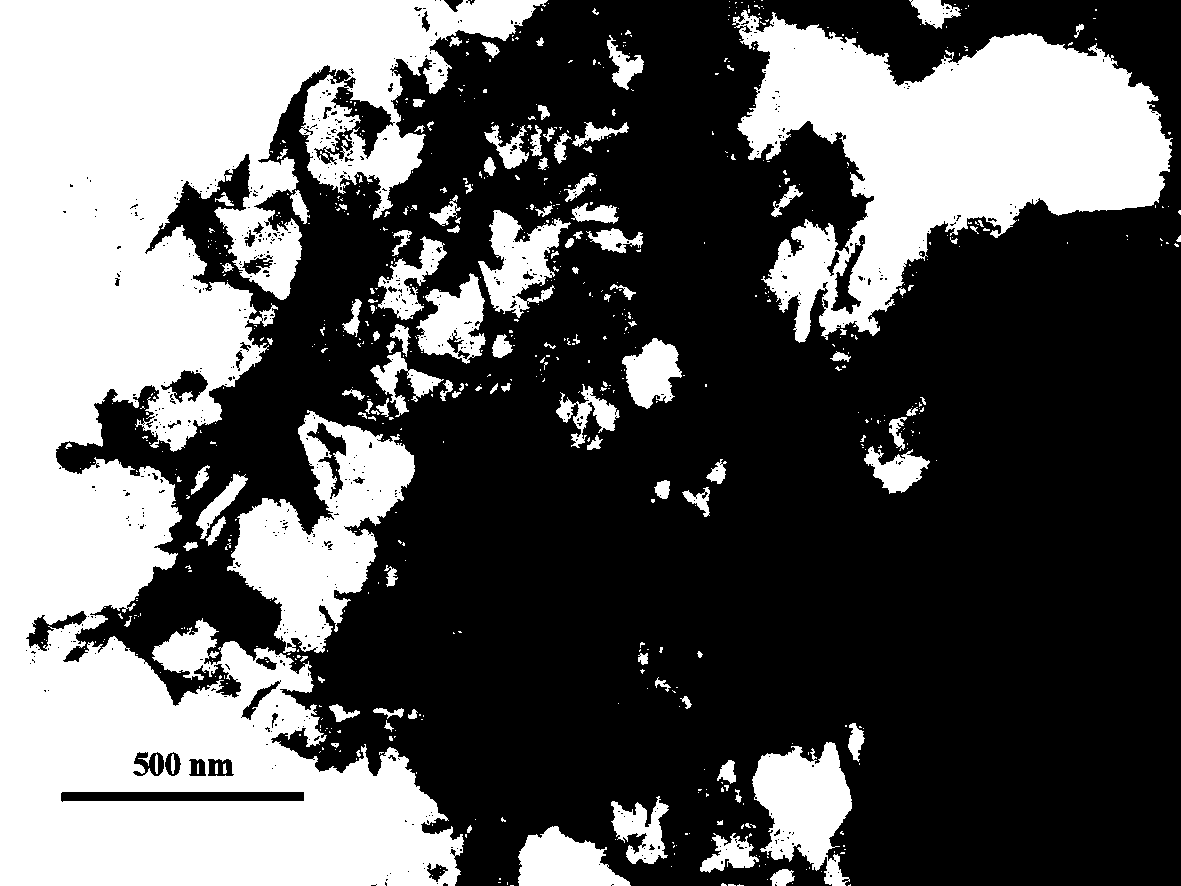

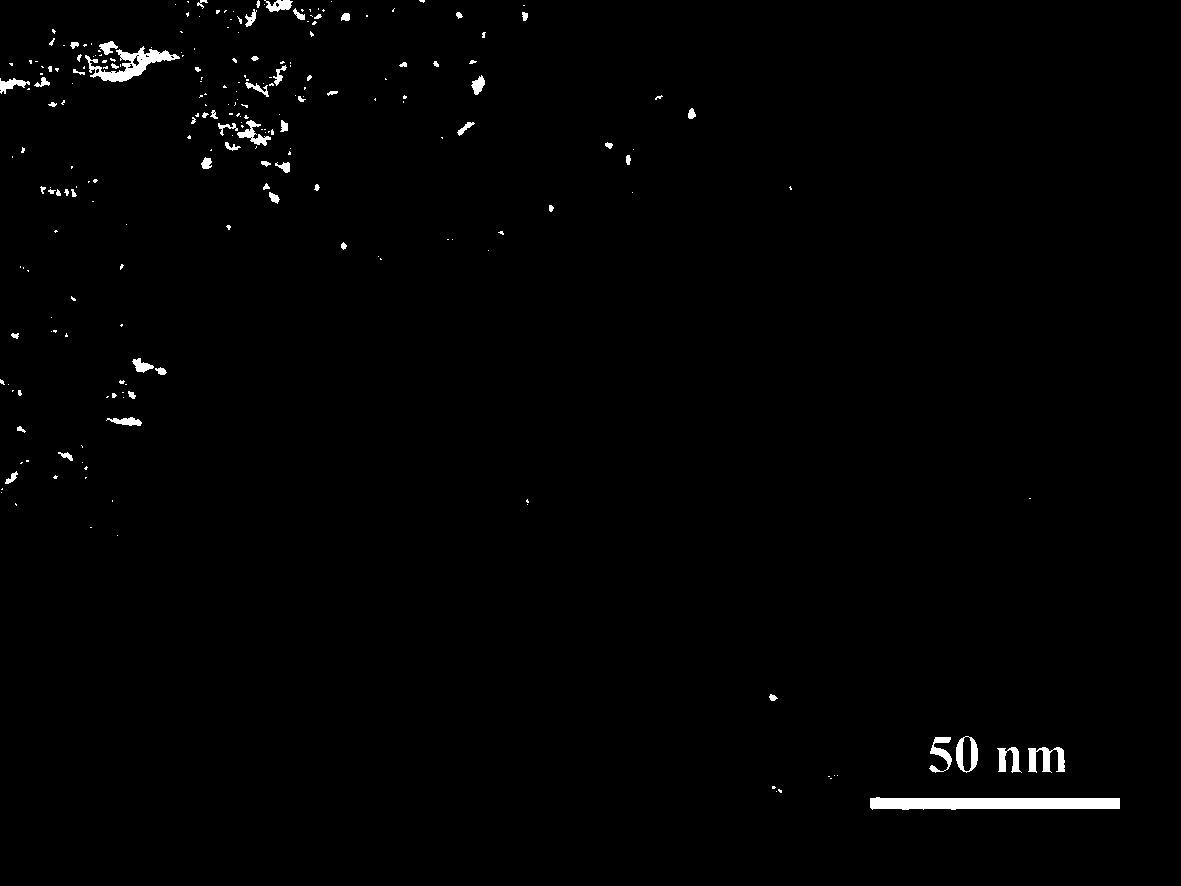

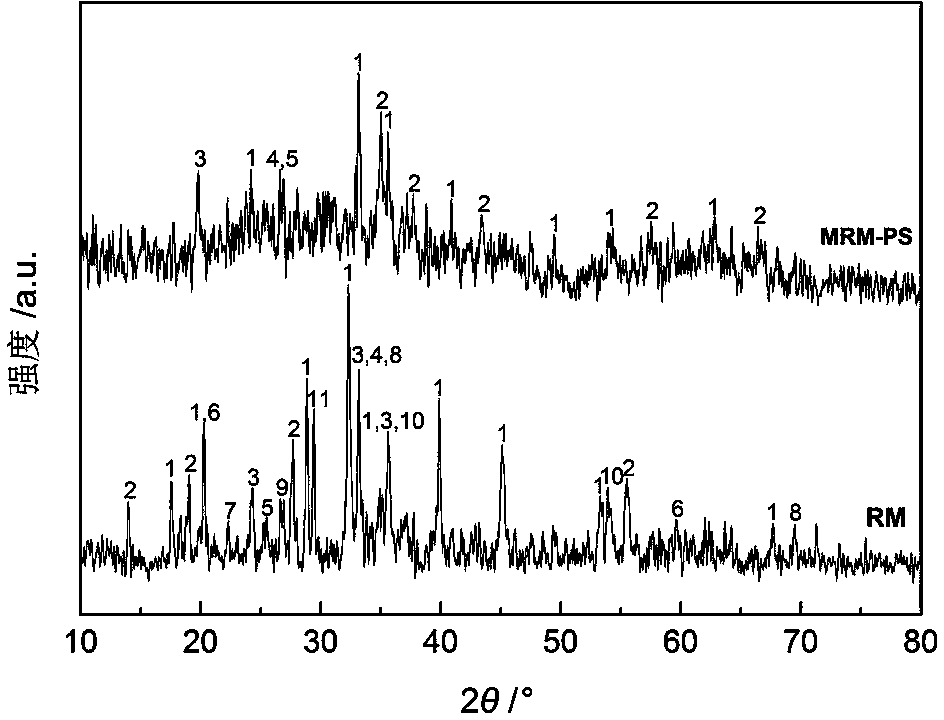

Image

Examples

preparation example Construction

[0024] A preparation method of a red mud adsorbent for removal of organic dye pollutants, the specific preparation steps are:

[0025] Step 1. At room temperature, take red mud and water according to the mass ratio of red mud and water of 1:4, and evenly disperse the red mud into the water under magnetic stirring to form an aqueous red mud solution for later use;

[0026] Step 2. At 80-90°C, add an aqueous hydrochloric acid solution with a concentration of 6 mol / L that is 1.5 times the volume of the water taken in the above step 1 to the red mud aqueous solution prepared in the above step 1 under magnetic stirring, and continue to Stir magnetically at high temperature for 1.5-2.5 hours to obtain red mud turbid liquid, cool it to room temperature, and set aside;

[0027] Step 3, under normal temperature, prepare ethanol aqueous solution according to the volume ratio of water and ethanol as 3:2; Polystyrene microspheres and the prepared ethanol aqueous solution are uniformly mi...

Embodiment 1

[0033] A preparation method of a red mud adsorbent for removal of organic dye pollutants, the specific preparation steps are:

[0034] Step 1. At room temperature, take red mud and water according to the mass ratio of red mud and water of 1:4, and evenly disperse the red mud into the water under magnetic stirring to form an aqueous red mud solution for later use;

[0035]Step 2. At 80°C, add an aqueous hydrochloric acid solution with a concentration of 6 mol / L that is 1.5 times the volume of the water taken in the above step 1 to the red mud aqueous solution prepared in the above step 1 under magnetic stirring, and continue at this temperature After magnetic stirring for 1.5 hours, the red mud turbid liquid was obtained, which was cooled to room temperature and set aside;

[0036] Step 3, under normal temperature, prepare ethanol aqueous solution according to the volume ratio of water and ethanol as 3:2; Polystyrene microspheres and the prepared ethanol aqueous solution are u...

Embodiment 2

[0042] A preparation method of a red mud adsorbent for removal of organic dye pollutants, the specific preparation steps are:

[0043] Step 1. At room temperature, take red mud and water according to the mass ratio of red mud and water of 1:4, and evenly disperse the red mud into the water under magnetic stirring to form an aqueous red mud solution for later use;

[0044] Step 2. At 90°C, add an aqueous hydrochloric acid solution with a concentration of 6 mol / L that is 1.5 times the volume of the water taken in the above step 1 to the red mud aqueous solution prepared in the above step 1 under magnetic stirring, and continue at this temperature After 2.5 hours of magnetic stirring, the red mud turbid liquid was obtained, which was cooled to room temperature and set aside;

[0045] Step 3, under normal temperature, prepare ethanol aqueous solution according to the volume ratio of water and ethanol as 3:2; Polystyrene microspheres and the prepared ethanol aqueous solution are u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com