Reflector for light-emitting diode and housing

A technology of light-emitting diodes and reflectors, which is applied in the field of reflectors, can solve the problems that fluororesin cannot be used and the reflectivity is reduced, and achieve the effect of high reflectivity and excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

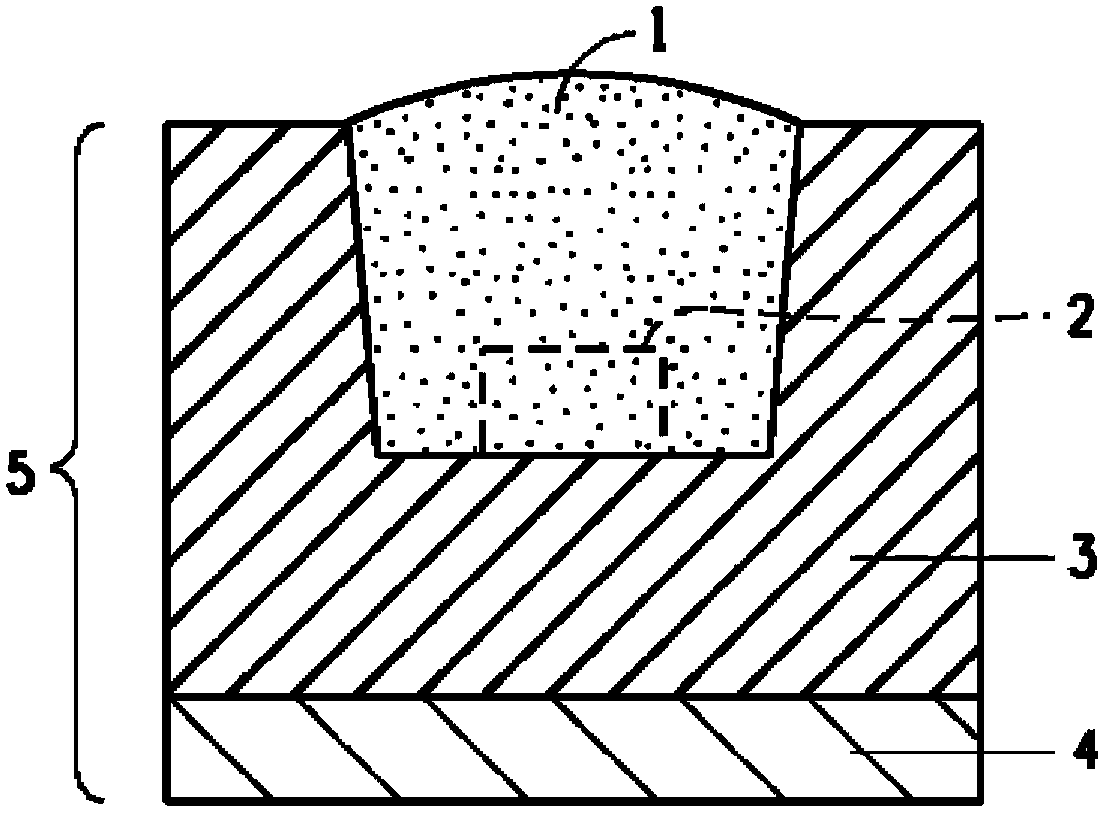

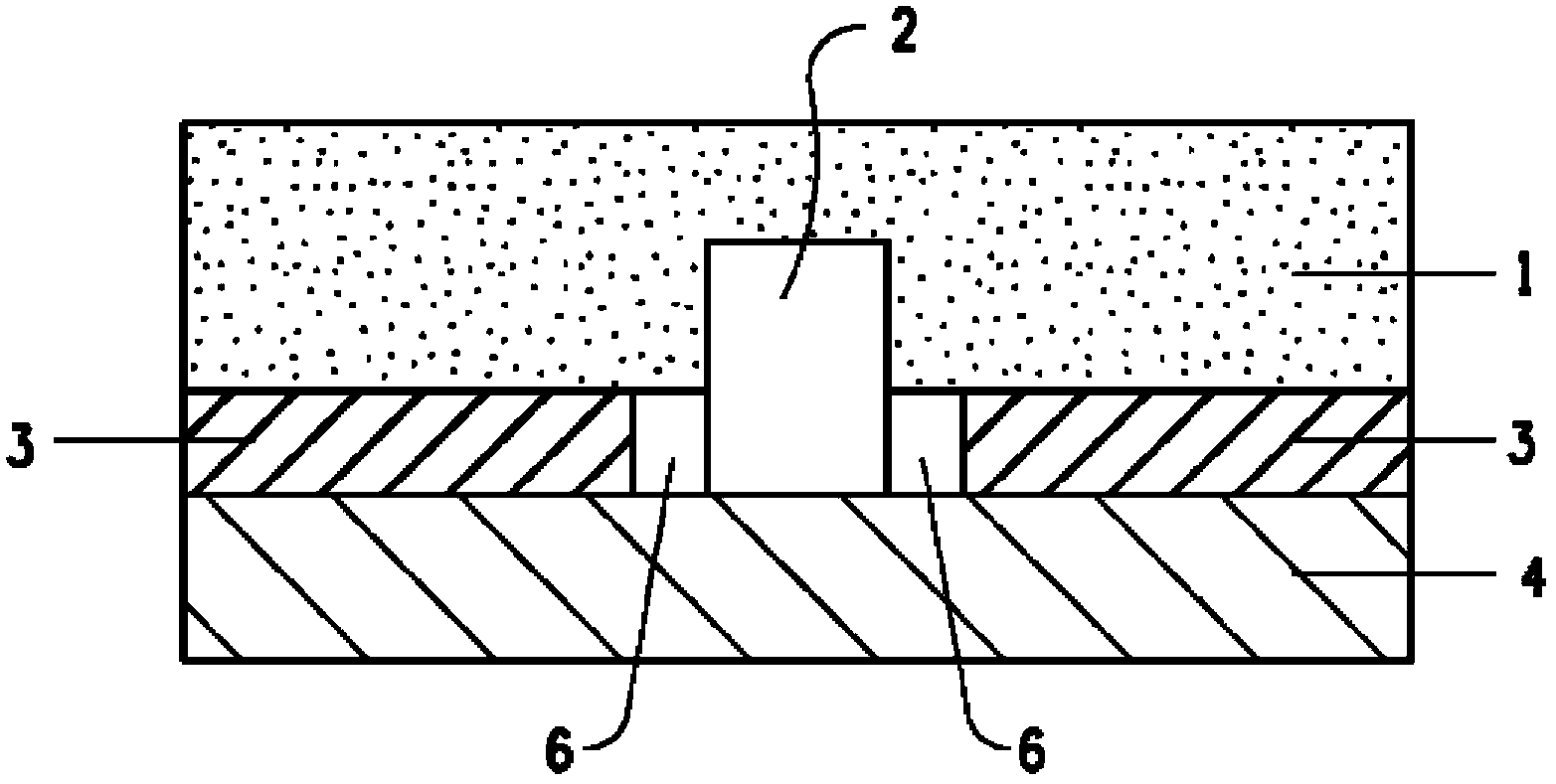

Image

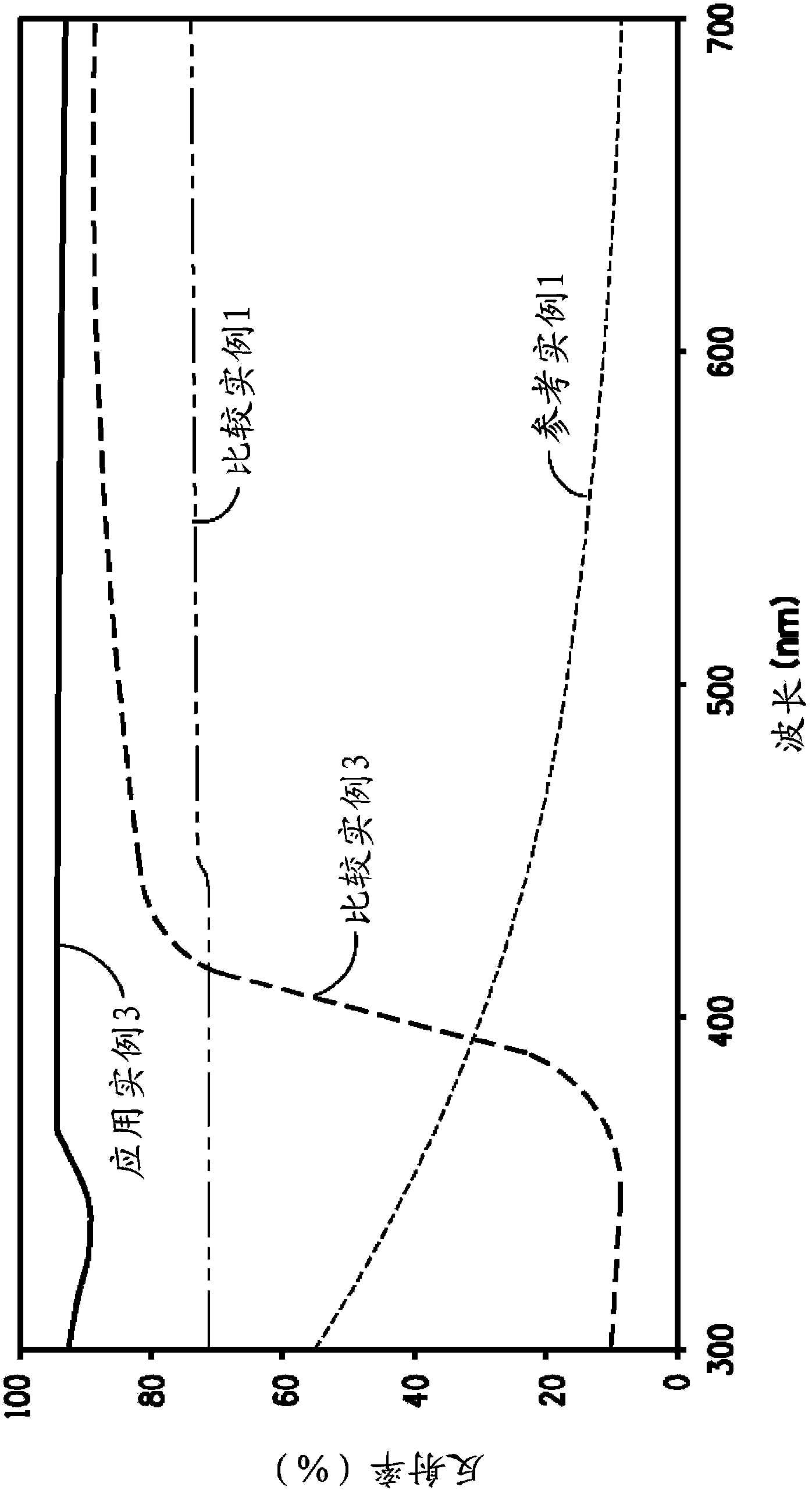

Examples

example

[0058] Next, the present invention will be explained in more detail through application examples and comparative examples. However, the present invention is not limited by this explanation.

[0059] Each property in the present invention is measured by the following method.

[0060] A. Measurement of performance

[0061] (1) Melting point (melting peak temperature)

[0062] A differential scanning calorimeter (Pyris1 type DSC, manufactured by Perkin Elmer Co.) was used. Weigh about 10 mg of the sample, put it into a special aluminum pan, fold it with a special crimper, and put it in the DSC main body, and raise the temperature from 150°C to 360°C at 10°C / min. At that time, the melting peak temperature (Tm) was obtained from the obtained melting curve.

[0063] (2) Melt flow rate (MFR)

[0064] Using a melt indexer (manufactured by Toyo Seiki Co., Ltd.) for corrosion-resistant drums, molds, and pistons, based on ASTM D-1238-95, 5 g of sample powder was filled into a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com