Manufacturing method of array substrate, array substrate and display device

The technology of an array substrate and a manufacturing method, which is applied to the display field, can solve the problems of complex and cumbersome manufacturing process of the array substrate, low production efficiency, low economic benefit, etc., and achieves the effects of simple manufacturing steps, few manufacturing steps, and improved economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

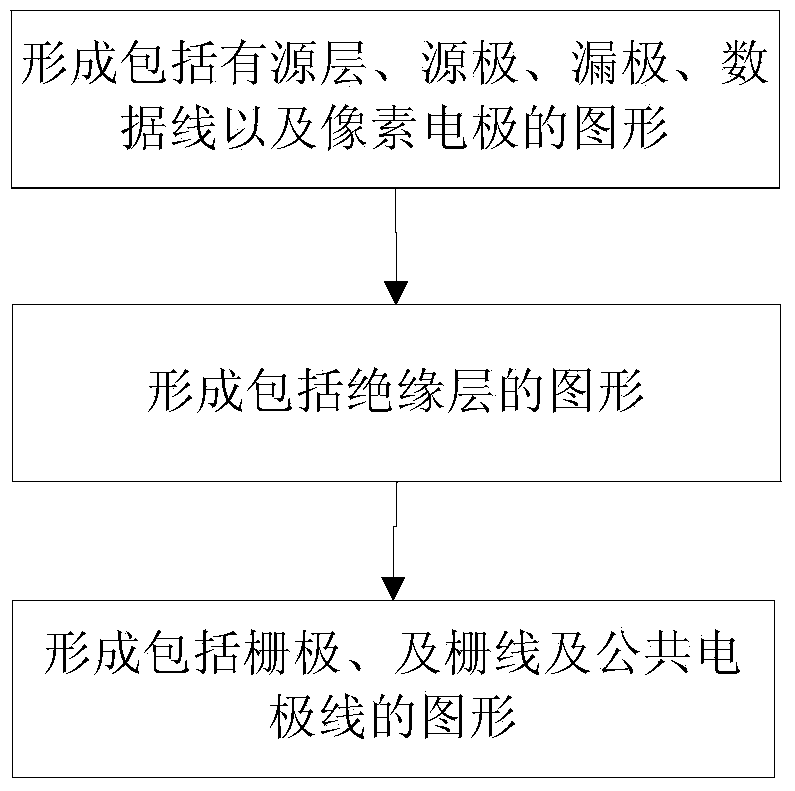

[0050] Such as figure 1 As shown, the fabrication method of the array substrate in this embodiment includes

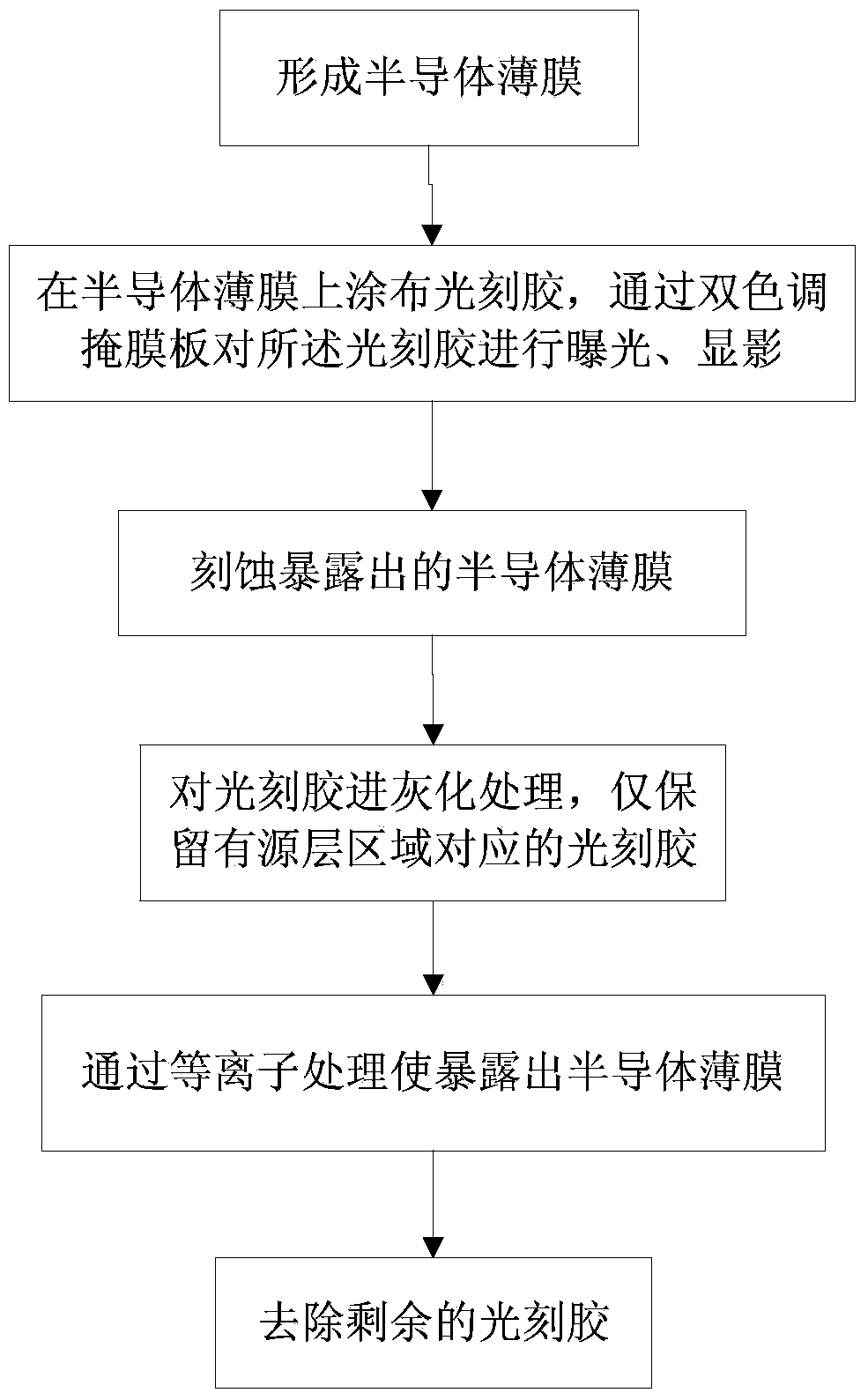

[0051] Step S1: forming a pattern including an active layer, a source electrode, a drain electrode, a data line, and a pixel electrode on the transparent substrate through a patterning process;

[0052] Step S2: forming a pattern including an insulating layer;

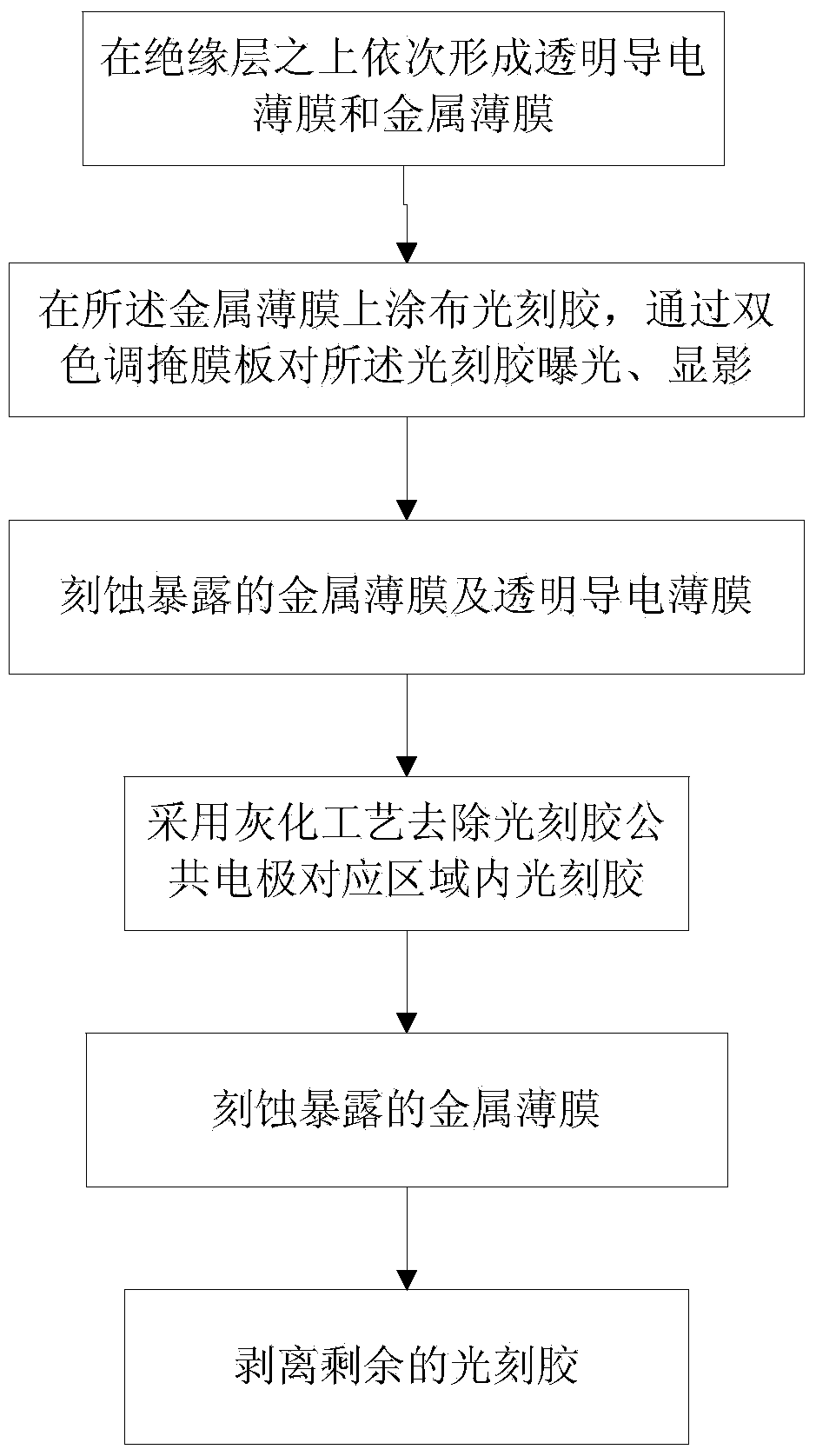

[0053] Step S3: forming a pattern including gates and gate lines through one patterning process.

[0054] In step S1, a pattern including an active layer, a source electrode, a drain electrode, a data line and a pixel electrode is formed through a patterning process;

[0055] In step S2, on the pattern formed in step S1, the pattern including the insulating layer is formed by depositing the insulating layer, wherein the deposition can be selected from any existing deposition method, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com