Enclosed evaporative cooling cold water set mist cooling system for power plant air cooling system

An evaporative cooling, chiller technology, applied in water shower coolers, direct contact heat exchangers, heat exchanger types, etc., can solve the heat exchange efficiency drop of air-cooled radiators, economic production problems of power plants, system back pressure It can improve the efficiency of air-cooled heat exchange, reduce coal consumption for power generation, and reduce operating energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

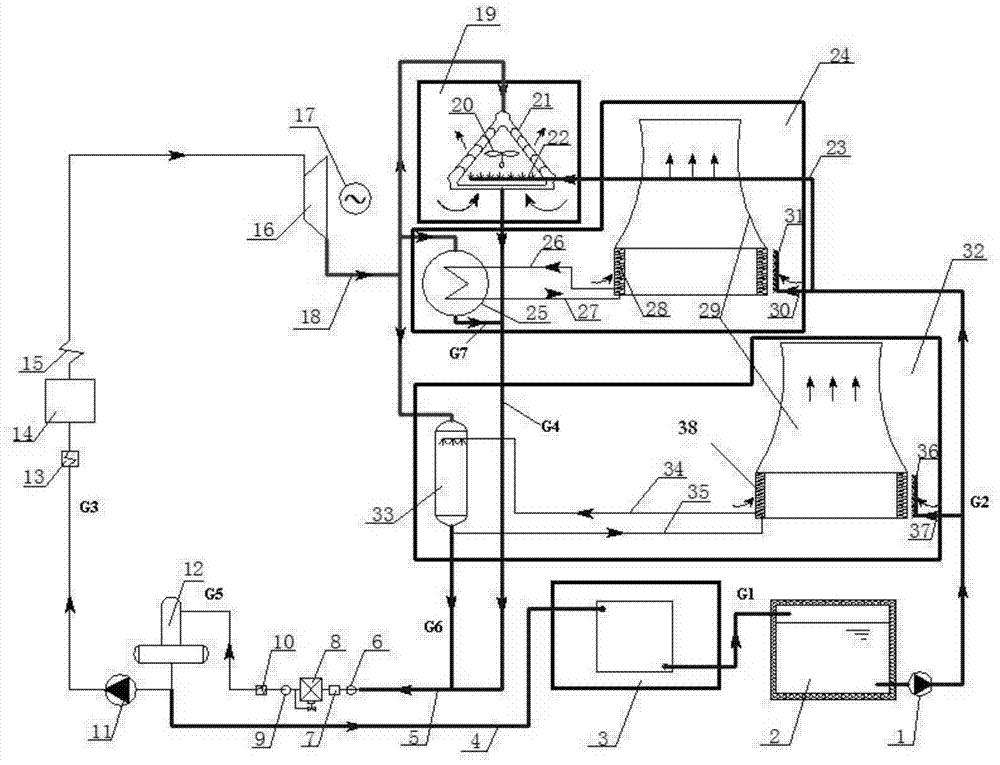

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0025] The air-cooling closed-type evaporative cooling chiller spray cooling system of the present invention has a structure such as figure 1 As shown, it includes a closed evaporative cooling chiller 3, and the closed evaporative cooling chiller 3 passes through the pipeline G 1 Connected with the water storage tank 2, the water storage tank 2 passes through the pipe G in turn 2 1. The spray pipe a23 is connected to the nozzle a22 in the direct air cooling device 19; the closed evaporative cooling chiller 3 is connected to the feed water pump 11 through the condensate return pipe a4, and the feed water pump 11 passes through the pipe G 3 Connect with high-pressure heater 13, boiler 14, superheater 15 and steam turbine 16 successively, steam turbine 16 is connected with steam turbine exhaust steam pipeline 18, steam turbine exhaust steam pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com