Device and method for accelerating gas generating speed by biomass pyrolysis and obtaining nanoscale carbon dioxide material

A technology of biomass pyrolysis and silica, which is applied in the direction of silica, silica, biofuel, etc., can solve the problems of tar condensation on the wall surface of combustion equipment, high energy consumption, and finding, and achieves improved efficiency and high drying speed , the effect of increasing the calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

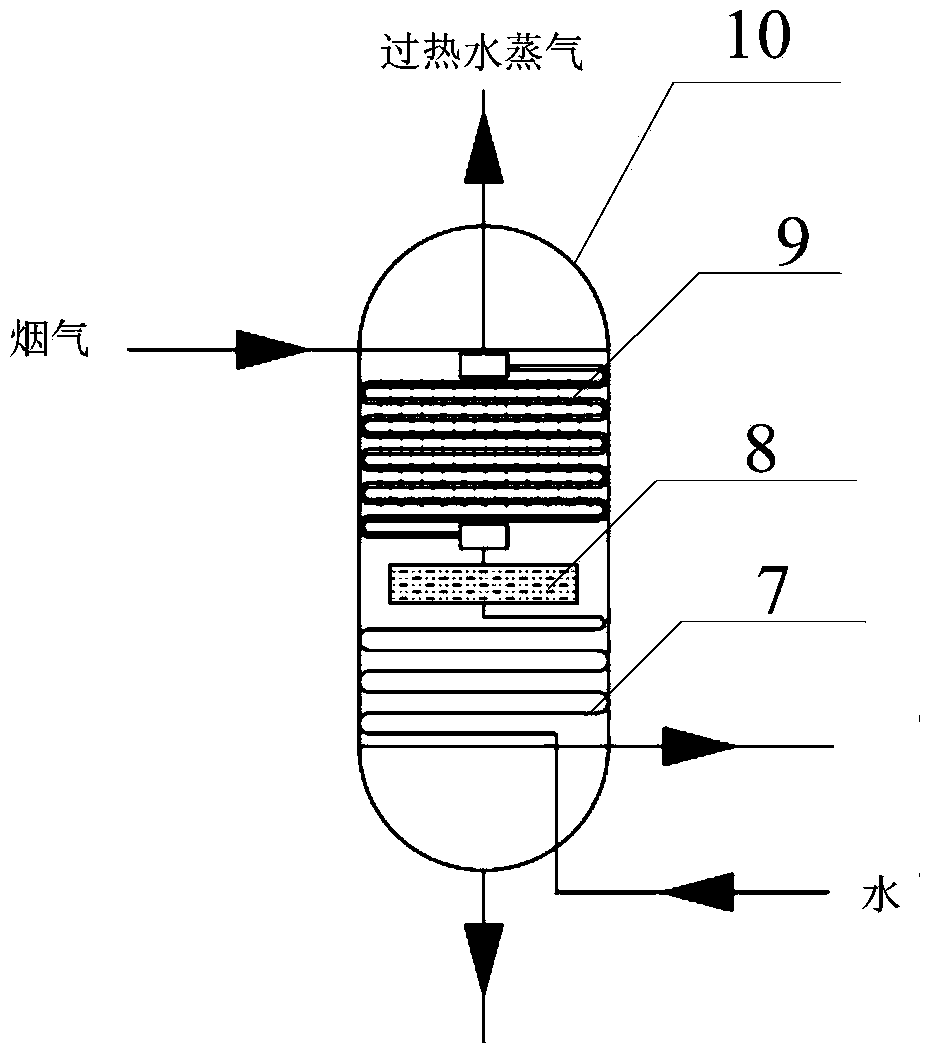

[0027] Such as figure 1 and figure 2 As shown, it is a device for accelerating biomass pyrolysis gas production speed and obtaining nano-scale silica materials provided in this embodiment, which includes a screw feeding device 1, a pretreatment agitator 2, a pyrolysis device 3, Combustion device 6, steam generator 4 and calcining device 5. The biomass raw material is sent into the pretreatment agitator 2 through the screw feeding device 1, and the stirred biomass raw material enters the pyrolysis device 3 after being mixed with the superheated steam produced by the steam generator 4, and the pyrolysis device 3 separates out The combustible gas enters the combustion device 6 for combustion, and the hot flue gas generated by the combustion device 6 heats the steam generator 4 to generate superheated steam, and the ash discharged from the ash port at the bottom of the pyrolysis device 3 enters the calcination device 5 for calcination . The steam generator 4 can be an electric...

Embodiment 2

[0038] This embodiment provides a method for accelerating biomass pyrolysis gas production speed and obtaining nano-scale silicon dioxide materials, which includes the following steps:

[0039] 1) The rice husk is simply screened and washed to remove impurities such as soil in the rice husk, and the rice husk is transported to the pretreatment agitator 2 through the screw feeding device 1, fully mixed with the water vapor from the subsequent process, and dried and heated;

[0040] 2) The mixed material is sent to the pyrolysis device 3, and is pyrolyzed in the range of 600°C in an oxygen-free environment, and the pyrolysis gas is rapidly generated and sent to the combustion device 6 to release heat.

[0041] 3) The waste heat flue gas enters the steam generator 4 to generate 150°C superheated steam, which is led back to the front-end pretreatment mixer 2 to mix and dry biomass raw materials.

[0042] 4) The pyrolyzed solid ash product is sent to the calcination device 5, and i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com