Manufacturing method for balance weight of compressor and balance weight manufactured by using manufacturing method

A manufacturing method and technology of a balance block, which are applied in the field of balance blocks, can solve problems such as general low density, and achieve the effect of expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

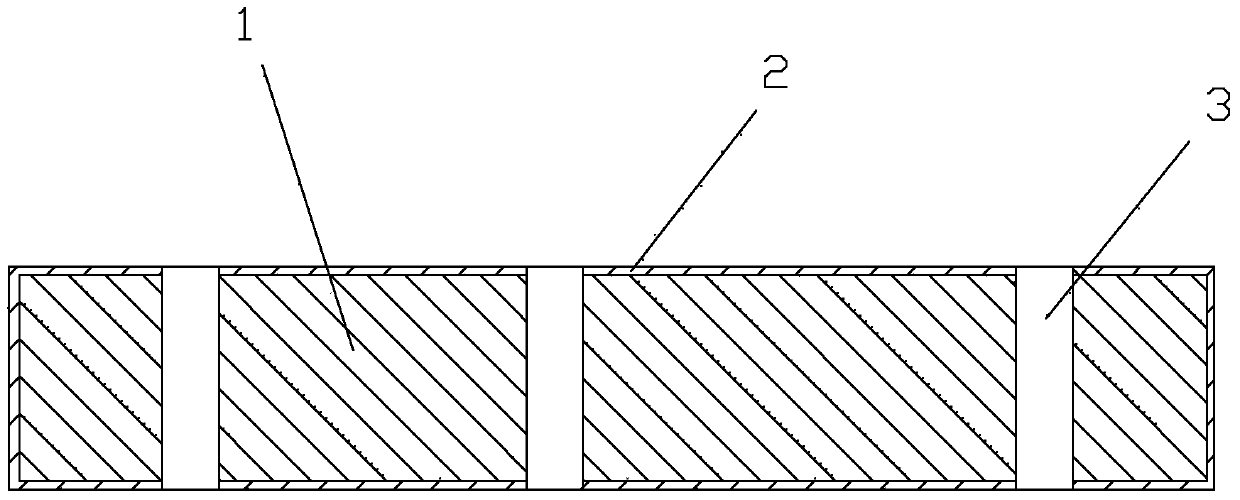

Image

Examples

Embodiment 1

[0023] A method for manufacturing a balance weight for a compressor, which is manufactured by powder metallurgy from alloy powder, comprising the following steps:

[0024] a) Put the raw materials including alloy powder and binder in a mixer and mix evenly. The weight percentage of each component of the raw material of alloy powder is: manganese (Mn) 17%, carbon (C) 0.5%, and the balance is Fe, and the binder accounts for 0.3-0.8% of the total weight of the first three components, and the binder is stearic acid.

[0025] b) sending the mixed materials into a powder press for compression molding to obtain a balance block compact;

[0026] c) Cover the outer surface of the balance block compact with a copper sheet, and then place it in a sintering furnace for sintering and solidification to manufacture a balance block sintered billet; the thickness of the copper sheet is 0.5mm; the sintering temperature is 1100°C;

[0027] d) Grinding and deburring the sintered body of the bala...

Embodiment 2

[0030] A method for manufacturing a balance weight for a compressor, which is manufactured by powder metallurgy from alloy powder, comprising the following steps:

[0031] a) Put the raw materials including alloy powder and binder in a mixer and mix evenly. The weight percentage of each component of the raw materials of alloy powder is: manganese (Mn) 20%, carbon (C) 1.0%, and the balance is Fe, and the binder accounts for 0.3-0.8% of the total weight of the first three components, and the binder is stearic acid.

[0032] b) sending the mixed materials into a powder press for compression molding to obtain a balance block compact;

[0033] c) Cover the outer surface of the balance block compact with a copper sheet, then place it in a sintering furnace for sintering and solidification to manufacture a balance block sintered billet; the thickness of the copper sheet is 5mm; the sintering temperature is 1150°C;

[0034] d) Grinding and deburring the sintered body of the balance b...

Embodiment 3

[0037] A method for manufacturing a balance weight for a compressor, which is manufactured by powder metallurgy from alloy powder, comprising the following steps:

[0038] a) Put the raw materials including alloy powder and binder in a mixer and mix evenly. The weight percentage of each component of the raw material of alloy powder is: manganese (Mn) 25%, carbon (C) 1.5%, and the balance is Fe, and the binder accounts for 0.3-0.8% of the total weight of the first three components, and the binder is stearic acid.

[0039] b) sending the mixed materials into a powder press for compression molding to obtain a balance block compact;

[0040] c) Cover the outer surface of the balance block compact with a copper sheet, and then place it in a sintering furnace for sintering and solidification to manufacture a balance block sintered blank; the thickness of the copper sheet is 10mm; the sintering temperature is 1200°C

[0041] d) Grinding and deburring the sintered body of the balance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com