Metal-coated powder surface alloying method

A surface alloying and metal cladding technology, applied in the direction of coating, etc., to achieve good corrosion resistance, good thermal spraying performance, and avoid the effect of fine powder scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

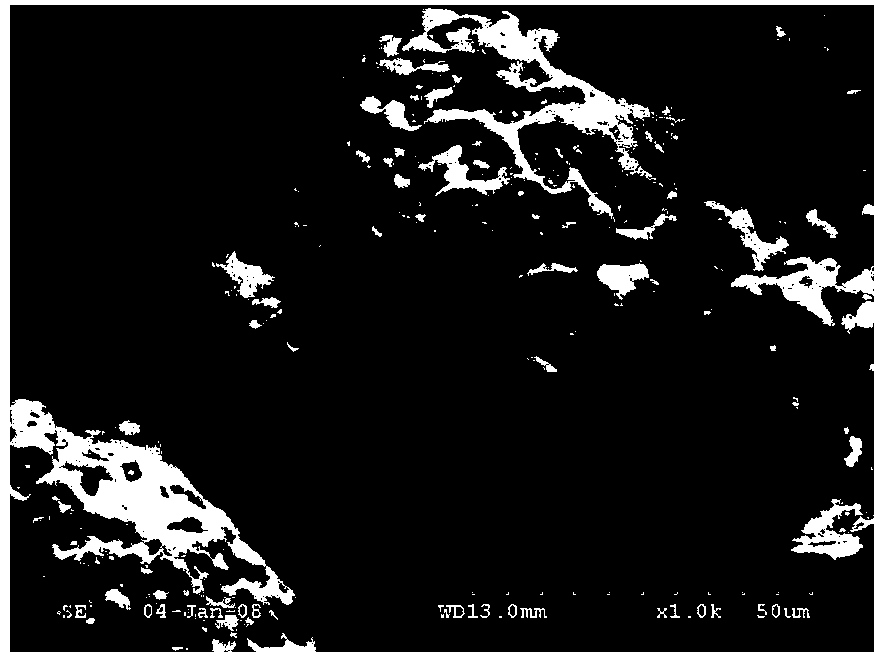

[0023] Take 100g of nickel-coated bentonite powder with a particle size of 45-150μm and a mass percentage of nickel of 65% and mix evenly with 10g of ultra-fine aluminum powder with a particle size of 2-10μm, and place the mixed powder in a high-temperature sintering furnace protected by high-purity hydrogen Carry out heat treatment, the heat treatment temperature is 900°C, and the heat treatment time is 2h. After heat treatment, cooling, crushing, and sieving, the morphology of the obtained nickel-aluminum-aluminum-coated bentonite powder is shown in the attached figure.

Embodiment 2

[0025] Take 100g of nickel-coated diatomite powder with a particle size of 45-200μm and a mass percentage of nickel of 70% and mix evenly with 10g of ultra-fine chromium powder with a particle size of 1-2μm, and place the mixed powder in a high-purity argon-protected Heat treatment is carried out in a high-temperature sintering furnace. The heat treatment temperature is 1200°C, and the heat treatment time is 2 hours. After heat treatment, it is cooled, crushed, and sieved.

Embodiment 3

[0027] Take 100g of nickel-coated graphite powder with a particle size of 45-200μm and a mass percentage of nickel of 75%, add 1wt% polyvinyl alcohol to mix and stir, and after the nickel-coated graphite powder is fully wetted, add 5g of nickel-coated graphite powder with a particle size of 30 The ~200nm ultra-fine aluminum powder is fully stirred, then dried to obtain agglomerated powder, and placed in a vacuum high-temperature sintering furnace for heat treatment. The heat treatment temperature is 600 ° C, and the heat treatment time is 72 hours. After heat treatment, it is cooled, crushed, and sieved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com