Grain drying device

A drying device and grain technology, applied in the direction of preserving seeds by drying, can solve problems such as restricting popularization and application, cracking, reducing grain quality and commodity value, etc., to achieve the improvement of commodity value, rapid heating, and avoiding grain leakage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is further described:

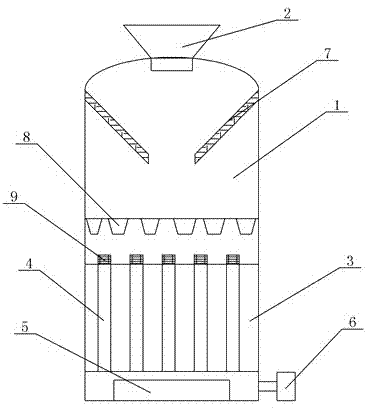

[0012] Such as figure 1 As shown, the present invention provides a grain drying device, which includes a preheating chamber 1, a drying chamber 3, and an electric heating chamber that can generate warm air in sequence from top to bottom. The top of the preheating chamber 1 is provided with a funnel-shaped feeding port 2. Inside the preheating chamber 1 below the feed port 2, a necked material baffle 7 is provided, and a plurality of necked material ejection ports 8 are arranged at the lower part of the preheating chamber 1. In the drying chamber 3 A plurality of ventilation pipes 4 with through holes are provided, and the top of the ventilation pipe 4 provided with a wind cap 9 communicates with the preheating chamber 1, and the wind cap 9 generates a suction capacity for the inside of the ventilation pipe 4, so that the outlet of the ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com