A permanent magnet synchronous motor current filtering and dead zone compensation device and compensation method

A technology of permanent magnet synchronous motor and dead zone compensation, which is applied to the control of electromechanical transmission, control of generator, motor generator control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

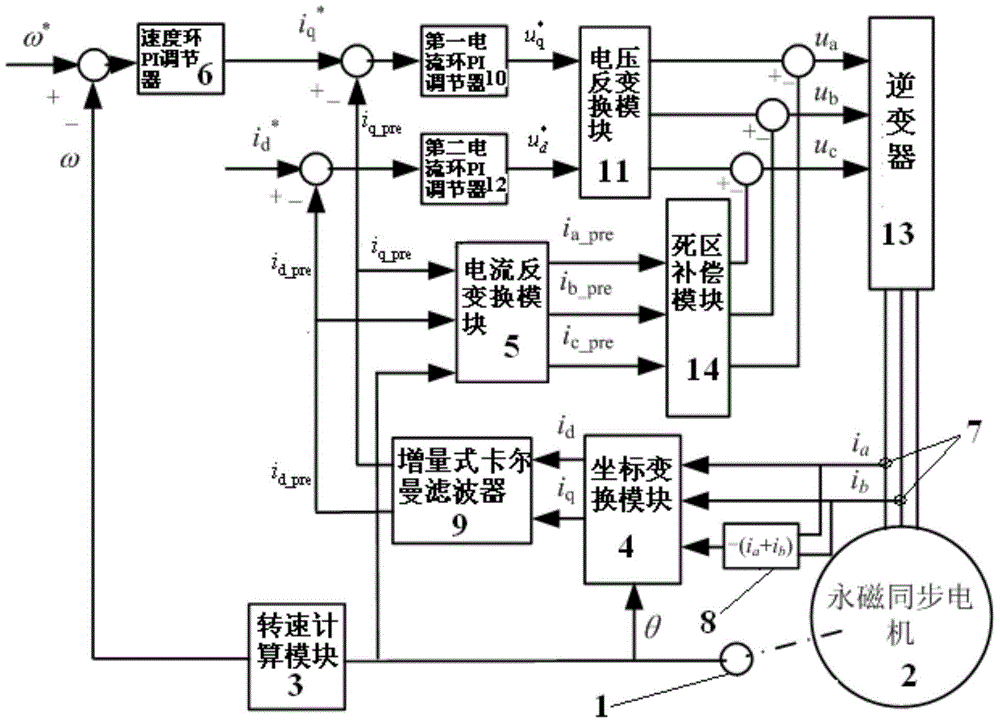

[0059] Such as figure 1 As shown, taking the permanent magnet synchronous motor servo system as an example, the present invention includes a position sensor 1, a permanent magnet synchronous motor (PMSM) 2, a speed calculation module 3, a coordinate transformation module 4, a current inverse transformation module 5, and a speed loop PI regulator 6. Current sensor 7, summation module 8, incremental Kalman filter 9, first current loop PI regulator 10, voltage inverse conversion module 11, second current loop PI regulator 12, inverter 13 and die Zone Compensation Module 14 . Wherein the coordinate transformation module 4, the incremental Kalman filter 9 and the first current loop PI regulator 10 constitute the q-axis current loop; the coordinate transformation module 4, the incremental Kalman filter 9 and the second current loop PI regulator 12 forms t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com