Secant-method based internal model position control method for permanent magnet linear synchronous motor

A permanent magnet synchronous linear and control method technology, which is applied in the direction of motor generator control, electronic commutation motor control, control system, etc., to achieve the effect of simple system structure, high matching accuracy, and avoiding network learning and adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Attached below Figure 1-4 , the technical solution of the present invention is described in detail.

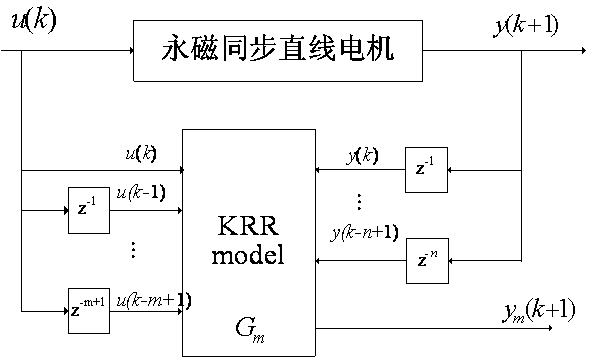

[0025] as attached figure 1 As shown, a permanent magnet synchronous linear motor chord method internal model position control method of the present invention is characterized in that: by connecting a permanent magnet synchronous linear motor in parallel with a nonlinear regression model based on nuclear ridge regression, using permanent magnet synchronous The difference between the displacement output value of the linear motor and the displacement output value of the regression model is fed back to the input terminal of the internal model controller through a low-pass filter, and then input to the chord controller to suppress the parameter change, model mismatch, and load disturbance; introduce kernel ridge regression into the internal model controller, use kernel ridge regression to construct the object model, and realize high-precision model construction; through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com