Method for manufacturing external electrode of dry-type multilayer ceramic capacitor

A technology of laminated ceramics and external electrodes, which is applied in the field of manufacturing external electrodes of dry-type laminated ceramic capacitors, can solve problems such as poor contact of external electrodes of chips, and achieve the effect of strengthening adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

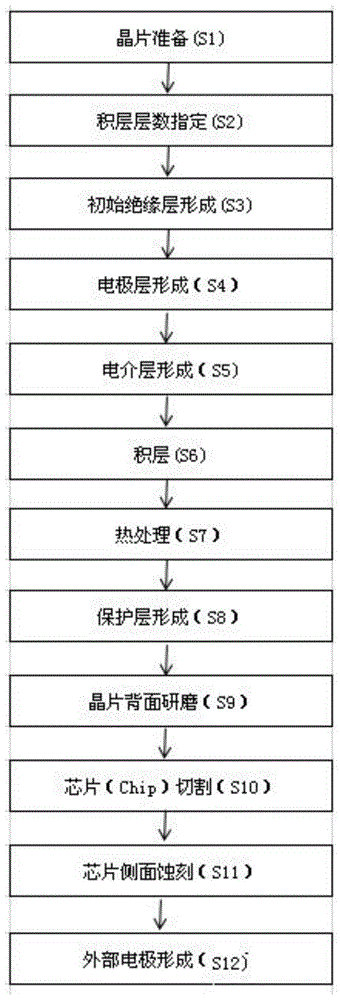

[0045] refer to figure 1 , dry-type laminated ceramic capacitor external electrode manufacturing method of the present invention is to utilize dry method to manufacture the method for high-quality capacitor (MLCC (Multi-Layer CeramicsCapacitor) by multi-layer vapor deposition on silicon wafer. Including S1: wafer preparation stage; S2: specify the electrode layer on the wafer and the stacked layer number stage of the dielectric layer; S3: the stage of forming the initial insulating layer on the wafer; S4: the stage of forming the electrode layer on the initial insulating layer; S5: on the electrode layer The stage of forming the dielectric layer; S6: the stage of repeatedly laminating the electrode layer and the dielectric layer; S7: the stage of heat treatment of the electrode layer and the dielectric layer after lamination; S8: the stage of forming a protective layer after heat treatment; S9: After the protective layer is formed, the wafer back grinding stage; S10: wafer ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com