A high-precision small-chip collage system for preparing monolithic integrated capacitive touch screens

A technology that integrates capacitors and touch screens, applied in the direction of electrical digital data processing, input/output process of data processing, instruments, etc., can solve the problems of low yield rate of finished products, environmental pollution, technical difficulties, etc. The effect of little pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] A high-precision small chip collage system for preparing a monolithic integrated capacitive touch screen, the system includes:

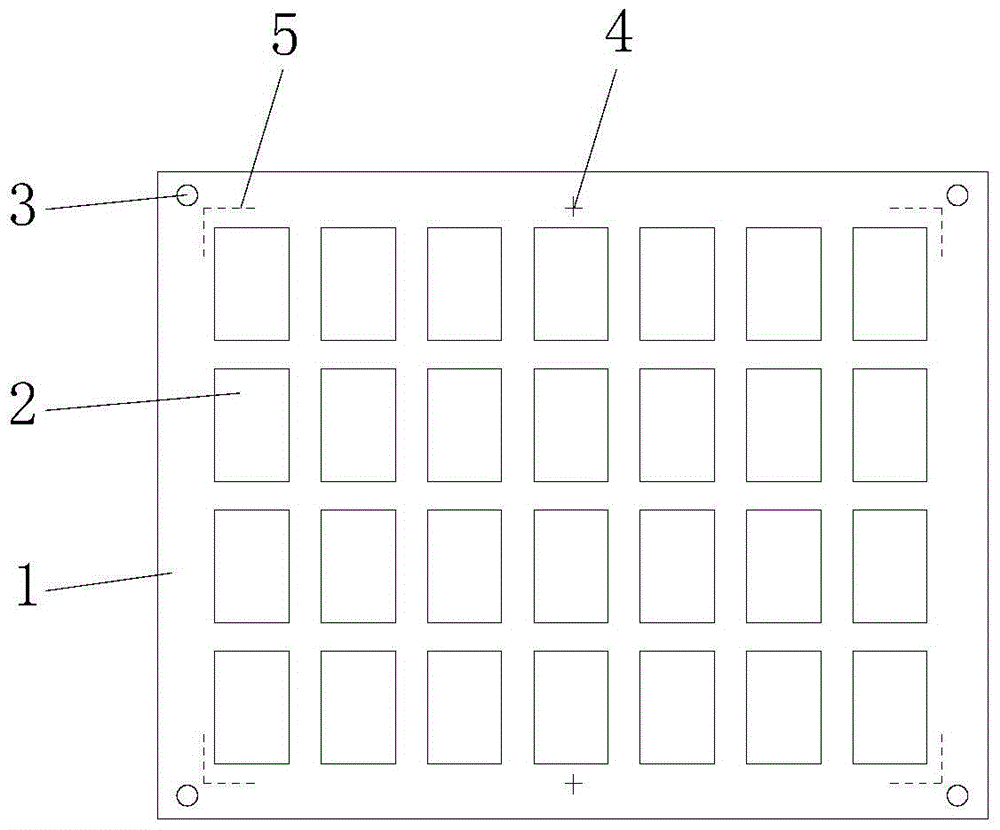

[0041] Bearing mother board: the structure of the bearing mother board is as follows figure 1 As shown, the carrying mother board 1 is a large piece of glass with a relatively large area, and is used to carry small pieces of glass 2. The carrying mother board is provided with an alignment mark for precise positioning, and the alignment mark includes an alignment origin hole 3 (circle holes or square holes), ITO alignment MARK4 and silk screen alignment MARK5.

[0042] Visual recognition system: mainly CCD camera system and image processing software system, used to identify the position information of the carrier motherboard and the coordinate positions of the small pieces of glass arranged on the carrier motherboard.

[0043] Mask system: used to design the filling pattern of the lithography mask and generate the coordinate position of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com