Combustion control system and control method for industrial furnace

An industrial kiln and control system technology, which is applied in the combustion method, combustion control, and fuel supply adjustment, etc., can solve the problems of increased fuel consumption, inability to real-time, and a large range of temperature control adjustment ranges, so as to reduce the amount of oxidative burning loss. , to avoid explosion accidents, the effect of excellent energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

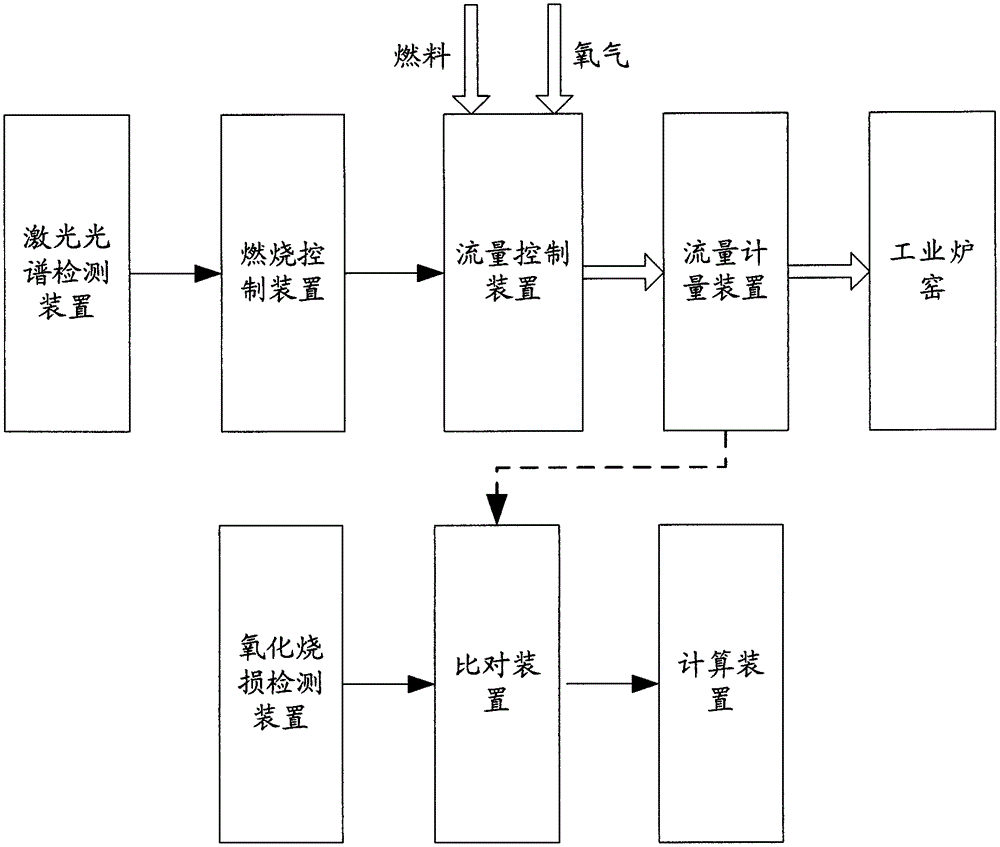

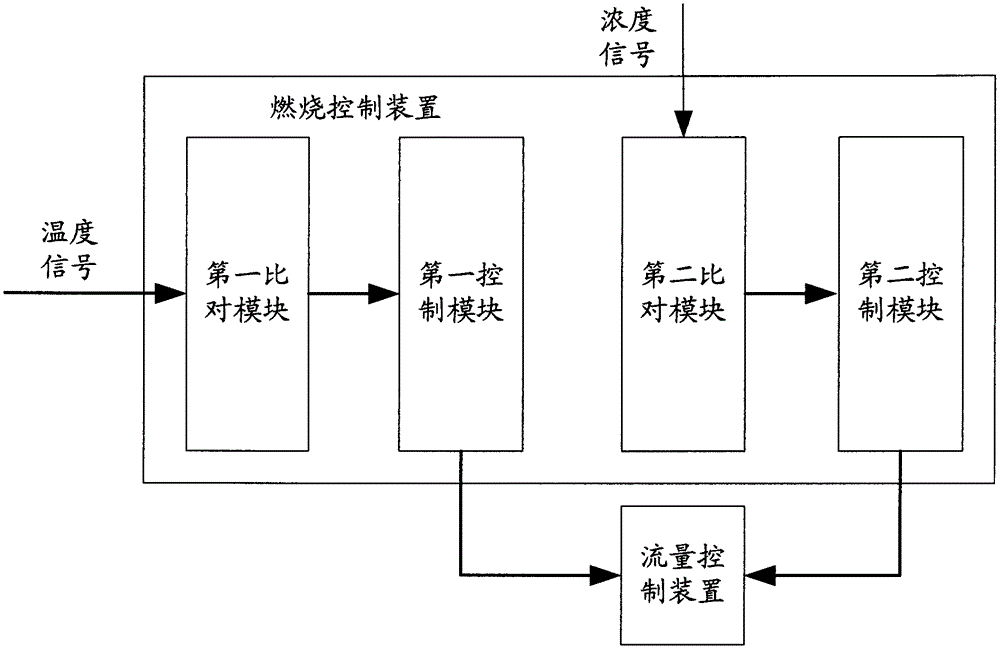

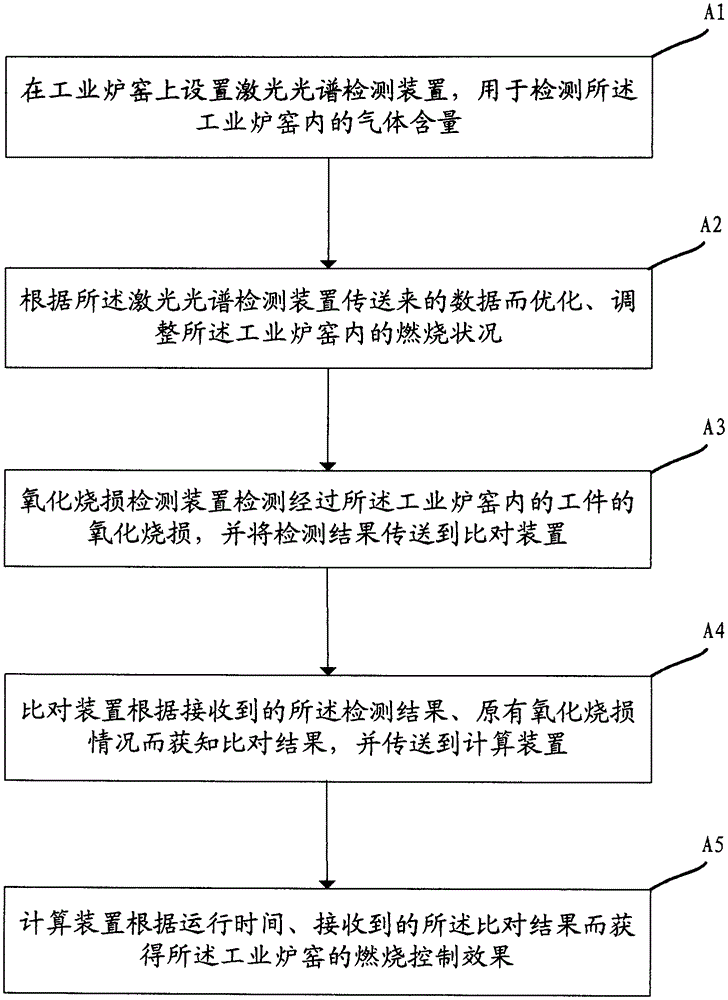

[0089] figure 1 Schematically provides the structural diagram of the combustion control system of the industrial furnace and kiln of the embodiment of the present invention, as figure 1 Shown, the combustion control system of described industrial kiln comprises:

[0090] A laser spectrum detection device, the laser spectrum detection device is arranged on the industrial furnace, for detecting the gas content in the industrial furnace, such as the content of oxygen and carbon monoxide; the laser spectrum detection device includes a laser, a detector and analysis modules. The laser and the detector can be installed on opposite sides of the industrial furnace respectively, so that the measurement optical path passes through the gas in the industrial furnace; the laser and the detector can also be installed on one side, and the light reflection component is installed on the opposite side. One side, so that the measuring light passes through the gas in the industrial furnace twic...

Embodiment 2

[0144] An application example of the combustion control system and control method of an industrial furnace according to Embodiment 1 of the present invention in a steel rolling heating furnace.

[0145] Figure 4 , 5 The horizontal and vertical installation diagrams of the laser spectrum detection device in this application example are respectively given, as shown in Figure 4 , 5 As shown, the heating furnace is divided into a preheating section, a heating section and a soaking section. The installation position of the laser spectrum detection device is as follows: at the height, it is 10-50 cm above the upper burner of each section; at this height position, the installation, It is easy to maintain, and the light path is good; in the horizontal direction, the preheating section: avoid the area affected by the air leakage of the steel inlet (2.2m away from the steel inlet side), and the center of the section is slightly biased towards the center of the two burners in the hea...

Embodiment 3

[0163] An application example of the combustion control system and control method of an industrial furnace according to Embodiment 1 of the present invention in a steel rolling heating furnace.

[0164] In this application example, the heating furnace is divided into a preheating section, a heating section, and a soaking section. The installation position of the first laser spectrum detection device is as follows: in height, it is between the burners of each section and the workpiece; In terms of position, it is convenient for installation and maintenance, and the optical path is good, which can better detect the combustion atmosphere of the workpiece accessories; in the horizontal direction, the preheating section: avoid the area affected by the air leakage of the steel inlet (2m away from the steel inlet side), and take the center of the section Slightly biased towards the center of the two burners in the heating section; heating section: take the center of the section; soaki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com