Polyurethane elastic fibers with multielement functionality and preparation method thereof

A polyurethane elastic and functional technology, which is applied in the field of preparation and application of glycyrrhetic acidified chitosan quaternary ammonium salt and its nanoparticles, can solve the problem that no glycyrrhetic acidified chitosan quaternary ammonium salt functional material, antioxidant performance degradation, complex synthesis methods, etc., to achieve broad industry application prospects, improve fracture strength, and simple preparation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A kind of preparation method of polyurethane elastic fiber with multiple functionalities of the present invention comprises the following steps:

[0037] (1) Prepolymerization reaction is carried out by polytetramethylene ether glycol and 4,4-diphenylmethane diisocyanate in N,N-dimethylacetamide solution, and then ethylenediamine, 1,2- A mixture of propylenediamine and diethylamine undergoes a chain extension reaction to obtain a polyurethane stock solution;

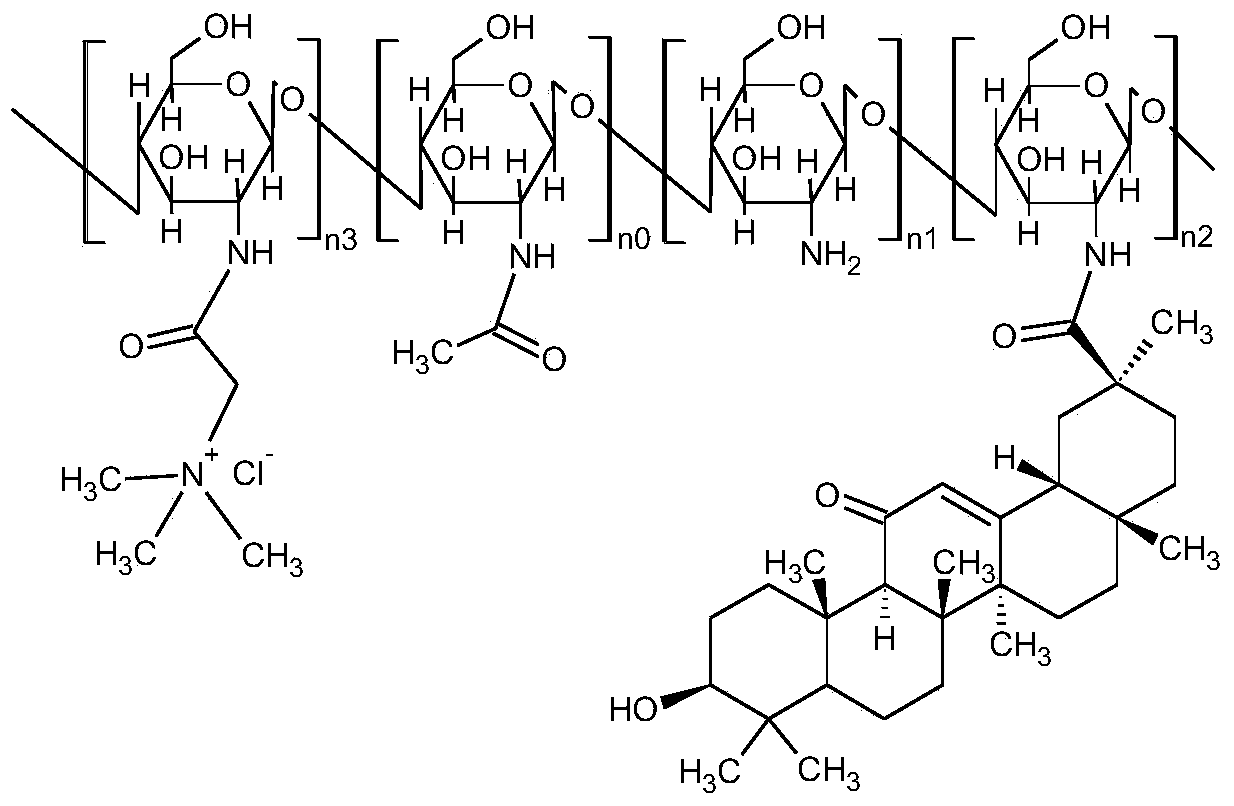

[0038] (2) Synthesis of glycyrrhetinated chitosan quaternary ammonium salt and prepared into nanoparticles;

[0039] (3) Glycyrrhetinated chitosan quaternary ammonium nanoparticles, N,N-dimethylacetamide, anti-ultraviolet additive UV-320, dyeing auxiliary agent SAS, matting agent titanium dioxide and lubricant magnesium stearate were mixed with A part of the above polyurethane stock solution is fully mixed in a grinder to form a low-viscosity additive slurry, and then added to the polyurethane stock solution to p...

Embodiment 1

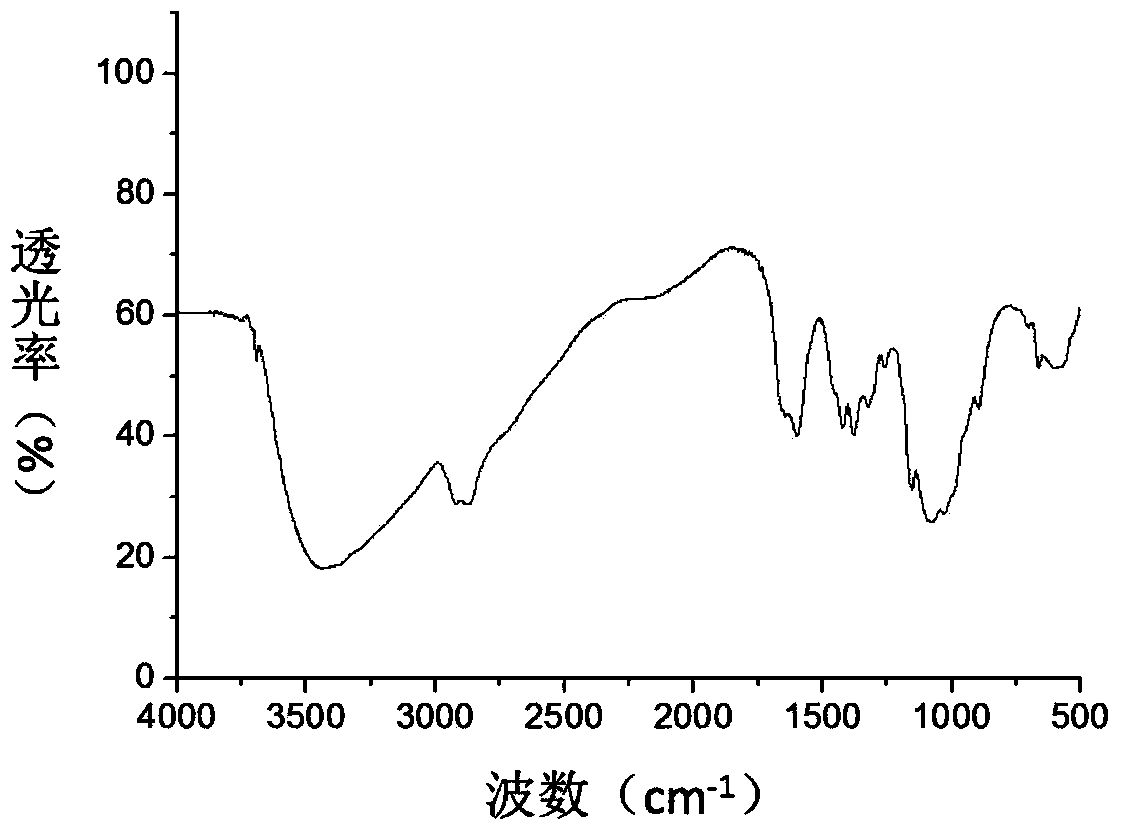

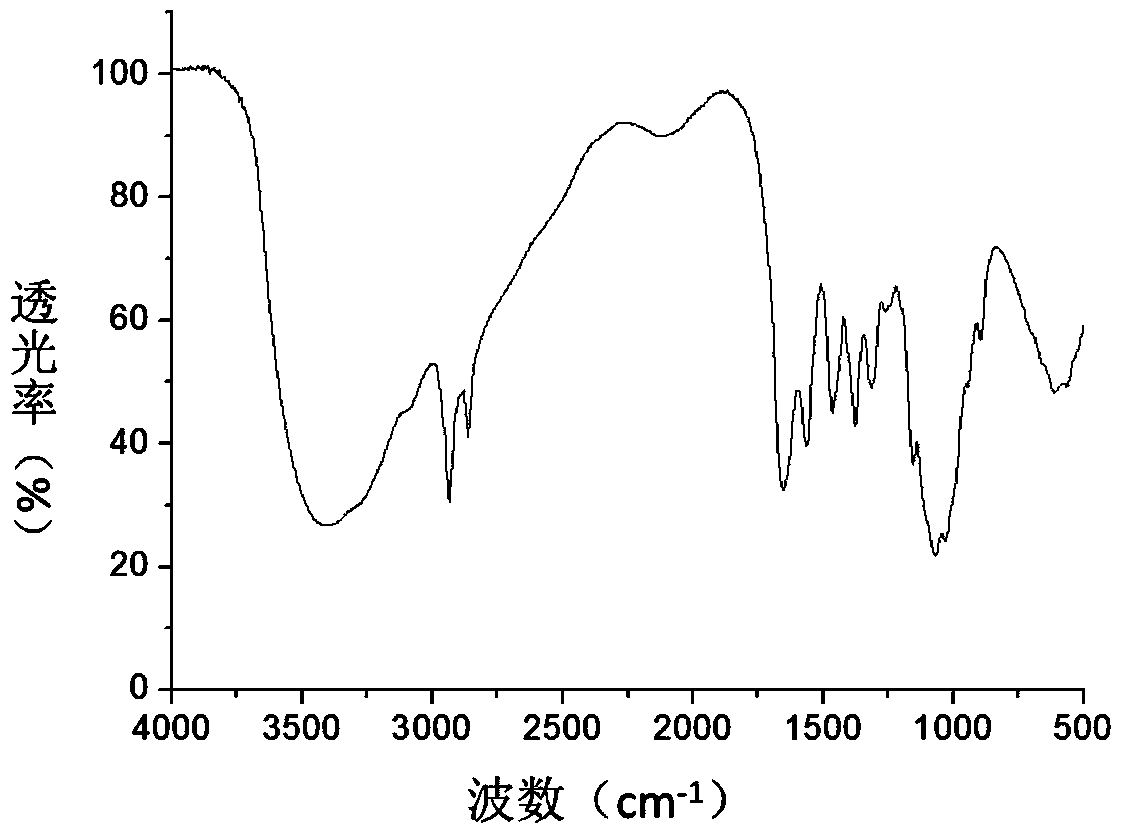

[0051] Step 1 Synthesis of Glycyrrhetinized Chitosan Quaternary Ammonium Salt: Dissolve 2g of chitosan with a molecular weight of 20,000 and a degree of deacetylation of 90% and 0.85g of betaine in 100ml of 2% (v / v) dilute acetic acid solution , adjust its pH to 5.5, add the catalyst EEDQ and mix and stir, react at room temperature for 12 hours, then acidify with concentrated hydrochloric acid to obtain the intermediate product, then adjust the pH to 3.5 after the intermediate product is dialyzed, and then add 80ml of 0.92g to the above solution EDC·HC1 and 0.56g NHS-activated DMF solution of 2.03g glycyrrhetinic acid, under the condition of magnetic stirring, reacted at room temperature for 12-72h, then left to precipitate with acetone, then washed the precipitate with ethanol and ether, vacuumed at room temperature After drying, the quaternary ammonium salt of glycyrrhetinated chitosan is obtained.

[0052] Step 2 Preparation of glycyrrhetinated chitosan quaternary ammonium ...

Embodiment 2

[0056] Polyurethane elastic fibers were prepared according to the same method described in Example 1, except that the amount of glycyrrhetinated chitosan quaternary ammonium salt nanoparticles added was 1.5 wt% relative to the solid content of the polyurethane spinning stock solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com