Controllable precursor passage

A precursor and channel technology, applied in the direction of single crystal growth, polycrystalline material growth, chemical instruments and methods, etc., can solve the problems of uneven radial distribution of the precursor flow field, which is not conducive to the growth of substrate materials, etc., and achieve growth thickness uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

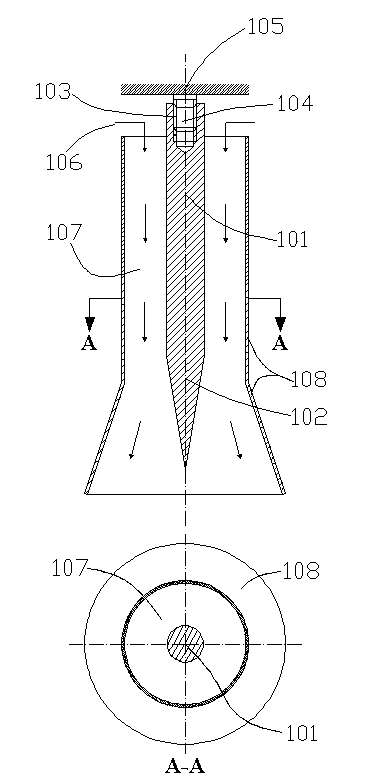

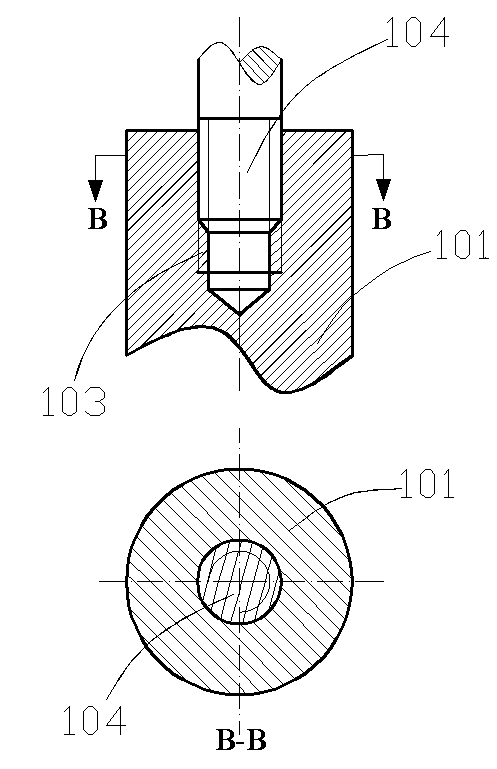

[0026] In a suspended vertical HVPE system, such as figure 1 As shown, the precursor gas flows from the terminal of the source gas supply system through the channel inlet 106 and enters the precursor channel 107; the outer wall 108 of the channel cavity is composed of two sections, the upper section is cylindrical, and the lower section is a skirt extension section , the height of the skirt and the expansion angle depend on the size of the substrate, the upper and lower sections are coaxial, and the diameters of the joints are equal. The central position of the channel 107 is a control rod, and the central position of the upper cylinder 101 of the control rod is provided with an internal thread sleeve hole 103, and the internal thread 103 matches the external thread of the stud 104, as figure 2 As shown; the stud 104 is a double-ended stud, one end of which is connected to the fixed wall 105 at the top of the precursor channel, and its body is connected to the stud 104 with t...

Embodiment 2

[0028] In this example, if figure 1 As shown, the precursor channel 107 is located in a vertical HVPE system, and the precursor is a nitrogen-containing gas or a group III halide gas, and the precursor gas enters the precursor channel 107 through the gas inlet 106 , the air inlet 106 is located between the top of the channel 105 and the top of the channel outer wall 108, the channel outer wall 108 is composed of a cylinder and a skirt body expansion section from top to bottom, the diameter of the upper end of the skirt body is consistent with the diameter of the cylinder, and the diameter of the skirt body The bulk expansion angle is determined by the effective area requirement of the growth material for the diffusion of the precursor. The center of the precursor channel 107 is a control rod, the control rod includes an upper cylinder 101 and a lower control end 102, the center of the top of the cylinder 101 has an internally threaded bushing 103, and the internally threaded b...

Embodiment 3

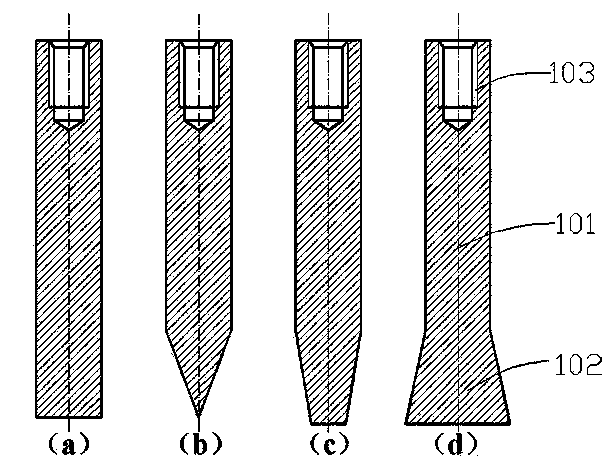

[0030] In this example, if Figure 4 As shown, in the hanging vertical HVPE system, the precursor channel 107 includes a precursor inlet 106 , an outer wall 108 of the channel, a central control rod of the channel and a fixed end 105 at the top of the channel. The precursor gas flows from the terminal of the source gas supply system through the channel inlet 106 and enters the precursor channel 107; the center of the channel 107 is a control rod, and the control rod includes upper and lower sections, and the upper section is a cylinder 101. The central position of the top of the cylinder 101 has an internally threaded sleeve hole 103, and the internally threaded sleeve hole 103 can be well connected with the stud 104, as figure 2As shown, the stud 104 is fixed to the fixed end 105 at the top of the precursor channel; the lower control end 102 is one of a cone, a circular frustum, an inverted circular frustum or a cylinder, respectively as image 3 As shown in (a), (b), (c) a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com