Double-layer rotary inner baffle for crystal growth by hydrothermal temperature difference method

A technology of crystal growth and temperature difference method, applied in the field of inner baffle, can solve the problems of crystal uniformity and Q value index decline, radial convection uneven, crystal growth rate slow down, etc., to meet the optical uniformity index, guarantee Upward channel, effect of changing convection state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

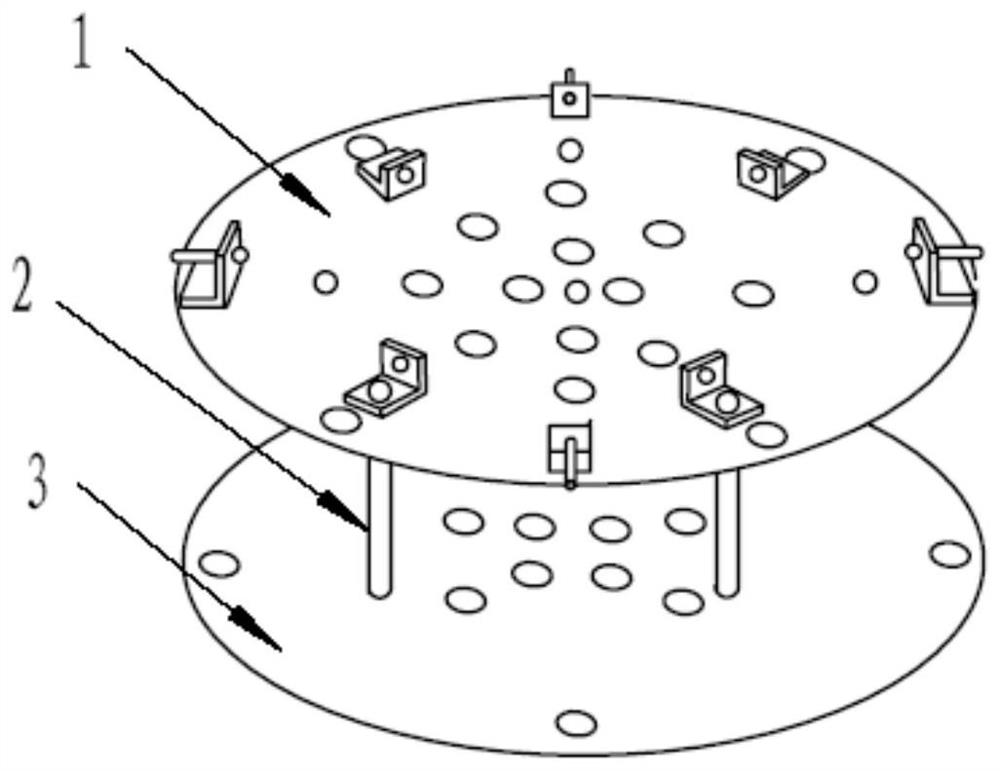

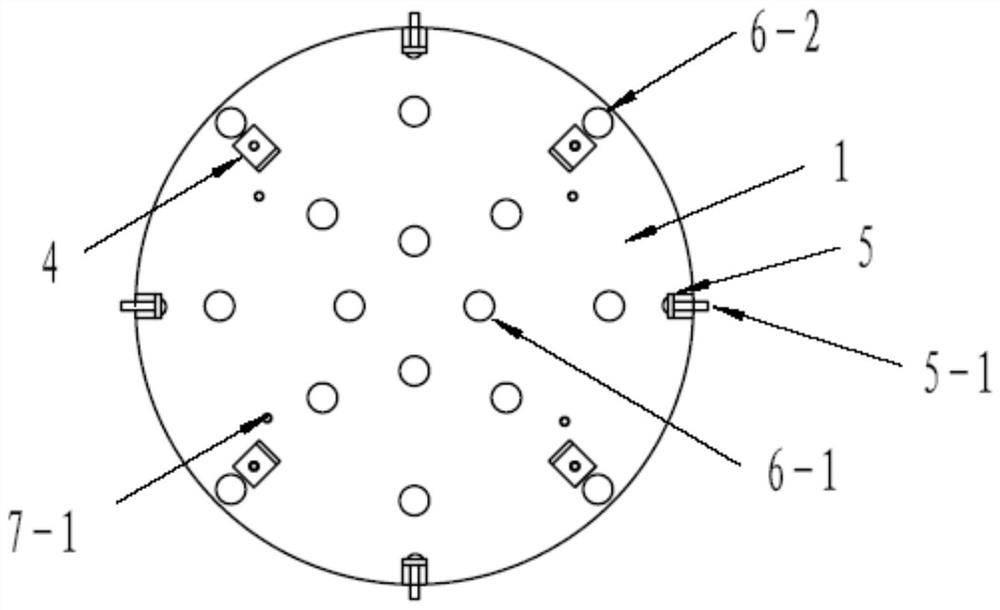

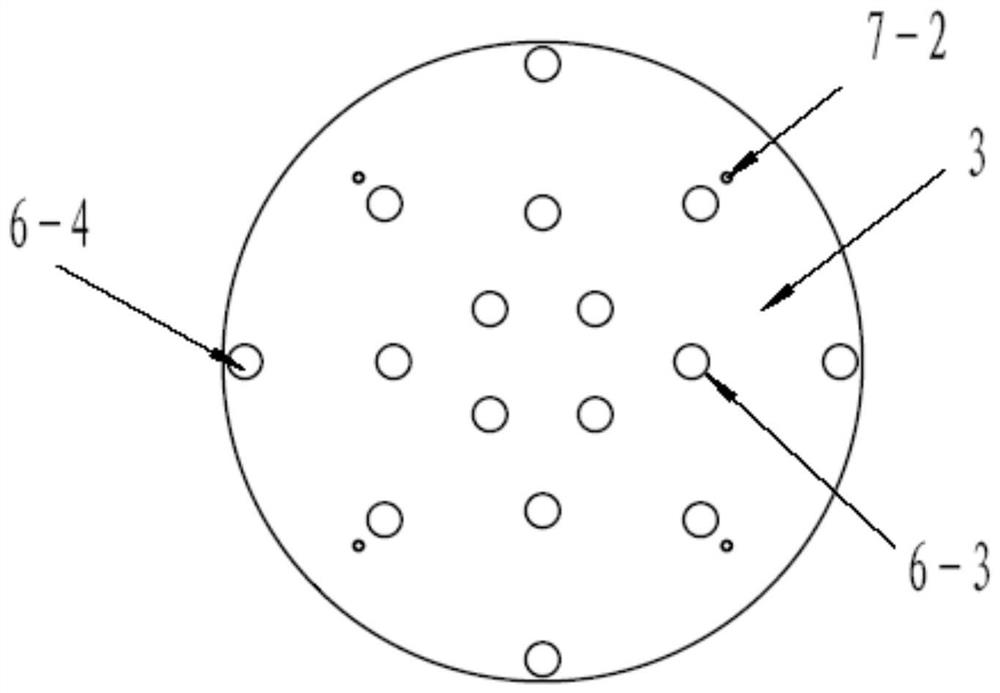

[0051] Embodiment 1. A double-layer rotating inner baffle for crystal growth by hydrothermal temperature difference method is placed in the inner cavity of a hydrothermal autoclave, such as Figure 1 ~ Figure 4 As shown, it includes upper baffle 1, baffle connecting column 2 and lower baffle 3; axis coincides with each other.

[0052] The upper baffle plate 1 and the lower baffle plate 3 are equal in size, that is, both have the same shape and size.

[0053] The upper baffle 1 is circular, and on the upper baffle 1 there are at least 2 concentric circles of mineralizer descending passages, and each circle of mineralizer descending passages includes at least 2 evenly arranged descending upper baffles Through holes 6-1; a circle of mineralizer ascending passages is evenly arranged at the edge of the upper baffle 1, and a circle of mineralizer ascending passages includes at least two upper baffle ascending through holes 6-2 evenly arranged; The ascending channel of the minerali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com