Zirconium-based MOF material-based zirconium oxide-coated lithium ion battery ternary positive electrode material and preparation method thereof

A technology for lithium-ion batteries and cathode materials, applied in battery electrodes, electrical components, secondary batteries, etc., can solve problems affecting practical applications, and achieve the effects of simple synthesis steps, high specific surface area, and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

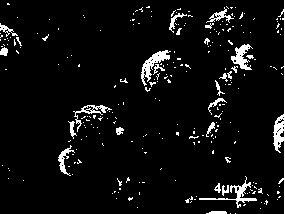

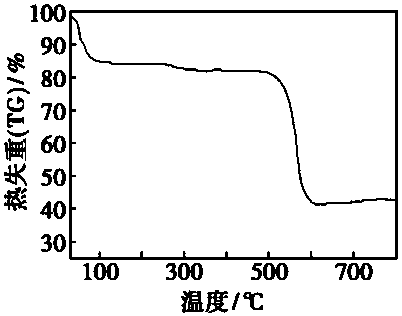

[0021] ZrO based on zirconium-based MOF materials 2 @LiNi 0.8 Co 0.1 Mn 0.1 O 2 Preparation of cathode materials

[0022] 1. Preparation of ternary positive electrode material for lithium ion battery: (a) Preparation of ternary positive electrode material precursor for lithium ion battery: according to the mole of n(Ni):n(Co):n(Mn)=8:1:1 Weigh nickel sulfate (NiSO 4 ·6H 2 O), cobalt sulfate (CoSO) 4 ·7H 2 O) and manganese sulfate (MnSO 4 ·H 2 O), dissolved in deionized water, prepared into a solution A with a metal ion concentration of 0.2 mol / L, then prepared a 0.6 mol / L sodium bicarbonate solution B, mixed solution A and solution B quickly together, the pH is 7.6~8.0, stir evenly at 20 °C and react for 3 hours, filter, wash, and vacuum dry at 80 °C to obtain spherical carbonate precursors for lithium-ion batteries, calcined at 500 °C for 5 hours to obtain spherical oxides for lithium-ion batteries Precursor. (b) Preparation of ternary cathode material for lithiu...

Embodiment 2

[0025] ZrO based on zirconium-based MOF materials 2 @LiNi 0.5 Co 0.2 Mn 0.3 O 2 Preparation of cathode materials

[0026] 1. Preparation of ternary cathode material for lithium ion battery: (a) Preparation of ternary cathode material precursor for lithium ion battery: according to the mole of n(Ni):n(Co):n(Mn)=5:2:3 Weigh nickel sulfate (NiSO 4 ·6H 2 O), cobalt sulfate (CoSO) 4 ·7H 2 O) and manganese sulfate (MnSO 4 ·H 2O), dissolved in deionized water, prepared into a solution A with a metal ion concentration of 0.4mol / L, then prepared a 1.2mol / L sodium bicarbonate solution B, mixed solution A and solution B quickly together, the pH is 7.6~8.0, stir evenly at 40°C and react for 4h, filter, wash, and vacuum dry at 90°C to obtain spherical carbonate precursors for lithium-ion batteries, calcined at 550°C for 6 hours to obtain spherical oxides for lithium-ion batteries Precursor. (b) Preparation of ternary cathode material for lithium ion battery: The pre-fired oxid...

Embodiment 3

[0029] ZrO based on zirconium-based MOF materials 2 @LiNi 0.6 Co 0.2 Mn 0.2 O 2 Preparation of cathode materials

[0030] 1. Preparation of ternary positive electrode material for lithium ion battery: (a) Preparation of ternary positive electrode material precursor for lithium ion battery: according to the mole of n(Ni):n(Co):n(Mn)=6:2:2 Weigh nickel sulfate (NiSO 4 ·6H 2 O), cobalt sulfate (CoSO) 4 ·7H 2 O) and manganese sulfate (MnSO 4 ·H 2 O), dissolved in deionized water, prepared into a solution A with a metal ion concentration of 0.6 mol / L, then prepared a 1.8 mol / L sodium bicarbonate solution B, mixed solution A and solution B quickly together, the pH is 7.6~8.0, stir evenly at 60°C and react for 5h, filter, wash, and vacuum dry at 100°C to obtain spherical carbonate precursors for lithium-ion batteries, calcined at 600°C for 8 hours to obtain spherical oxides for lithium-ion batteries Precursor. (b) Preparation of ternary cathode material for lithium ion b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com