Reversible crosslinking low-damage fracturing fluid thickening agent and production method thereof

A technology of thickening agent and fracturing fluid, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., and can solve problems such as poor shear resistance, poor high temperature stability, and system instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

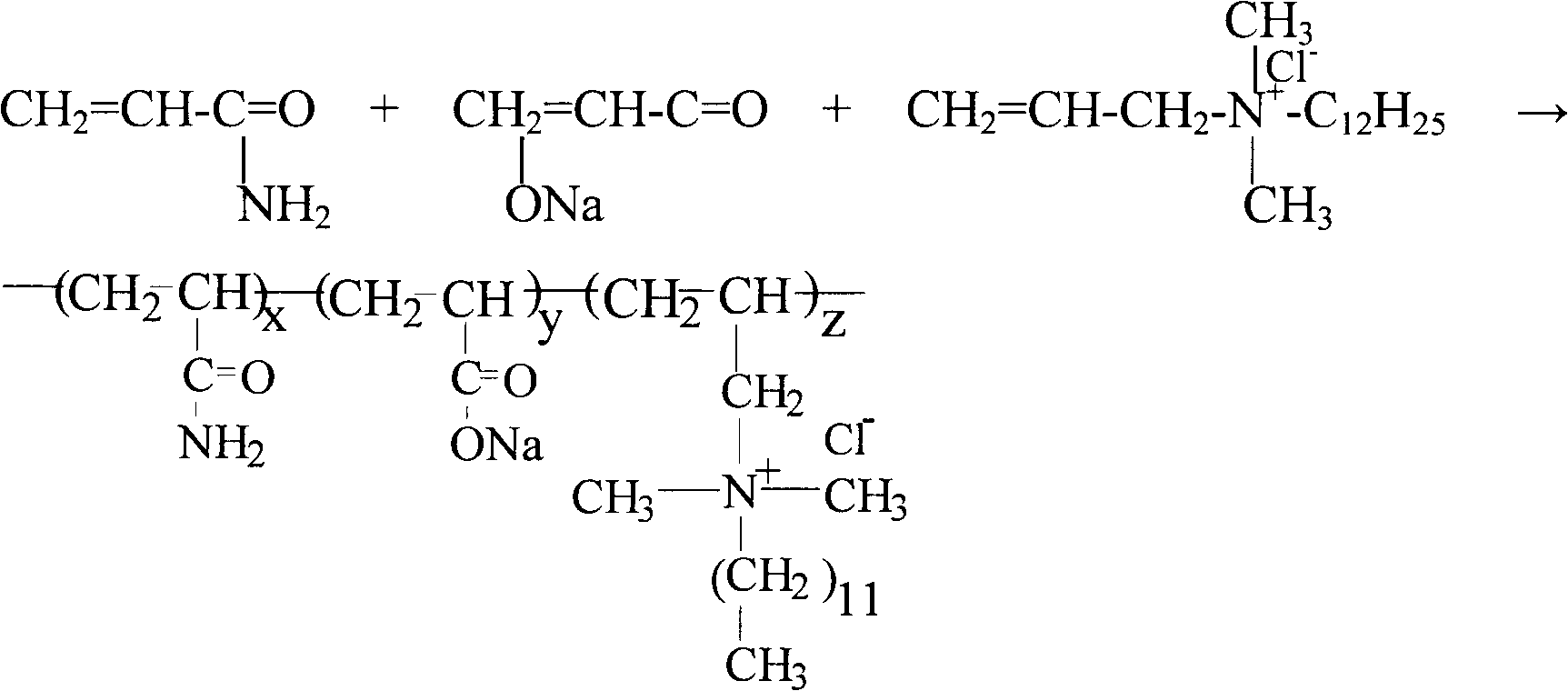

Method used

Image

Examples

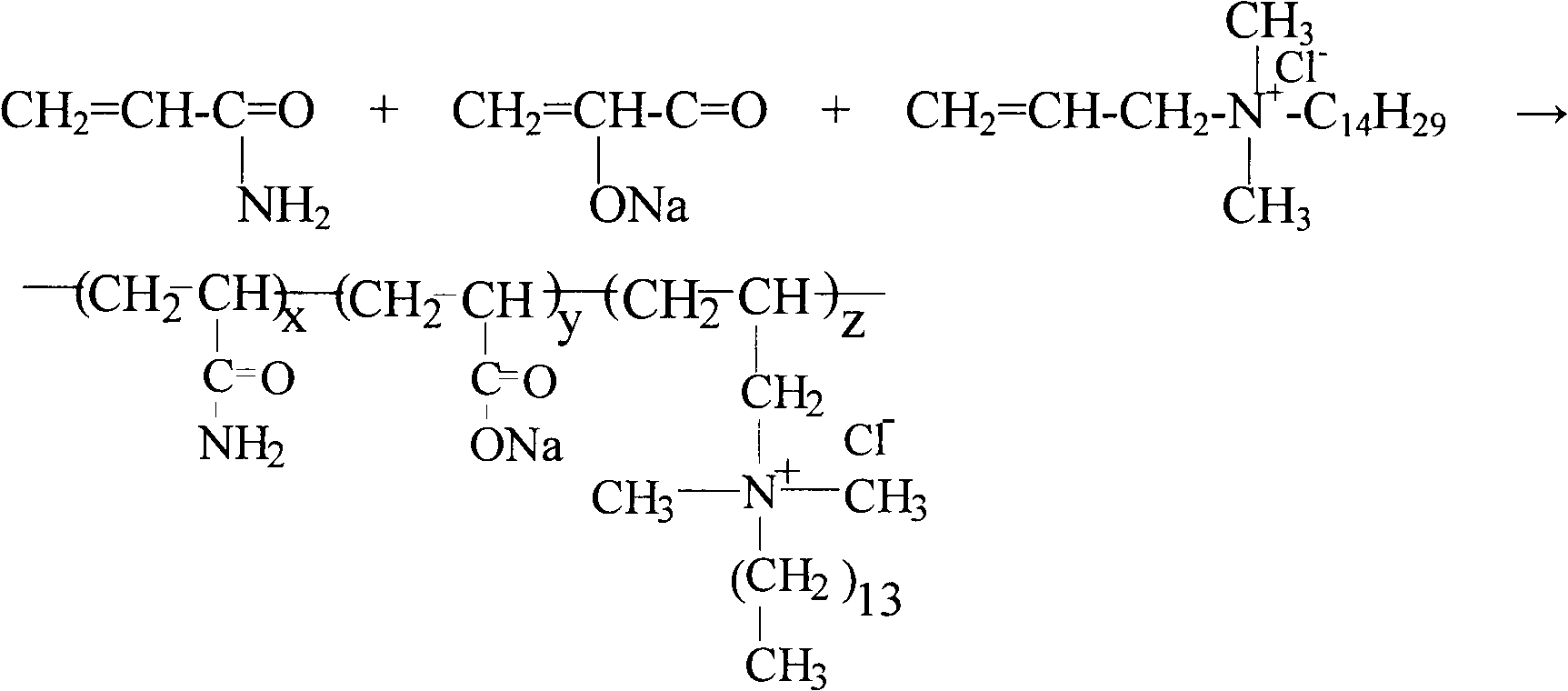

Embodiment 1

[0030] The weight percent of each monomer and water: AM:NaAA:C 14 DMAAC::H 2 O=15:5:0.7:79.3.

[0031] Preparation of the solution: Add 79.3g of distilled water to a 500mL beaker, add 15g of monomer A, add 5g of monomer B, add 0.7g of monomer C, adjust the pH to 7.5 with sodium hydroxide, blow in nitrogen, and stir for 30 minutes to dissolve , Adjust the temperature to 10±1°C.

[0032] Polymerization of the solution: In the above state, add the initiator ammonium persulfate, sodium bisulfite, and azobisisobutyronitrile totaling 0.8g, stop blowing nitrogen 30 minutes after initiation and seal the polymerization kettle, and put it in a heat-preserving and airtight condition at 45 degrees down until the end of heating.

[0033] Post-processing of the product: granulate the polymerized colloid, dry it, crush it into 20-40 mesh, and code it as G-1 for testing.

Embodiment 2

[0035] The weight percent of each monomer and water: AM:NaAA:C 12 DMAAC:H 2 O H 2 O=10:6:0.5:83.5.

[0036] Preparation of the solution: Add 83.5g of distilled water to a 500mL beaker, add 10g of AM monomer, add 6g of NaAA monomer, add C 12 0.5g of DMAAC monomer, adjust the pH to 8.5 with sodium bicarbonate, blow in nitrogen gas, stir and dissolve for 30 minutes, and adjust the temperature to 10±1°C.

[0037] Polymerization of the solution: In the above state, add the initiator ammonium persulfate, sodium bisulfite, and azobisisobutyronitrile totaling 1g, stop blowing nitrogen 30 minutes after initiation and seal the polymerization kettle, and put it under the condition of heat preservation and airtightness at 45 degrees until the end of heating.

[0038] Post-processing of the product: granulate the polymerized colloid, dry it, and crush it into 20-40 mesh, numbered G-2, waiting for inspection.

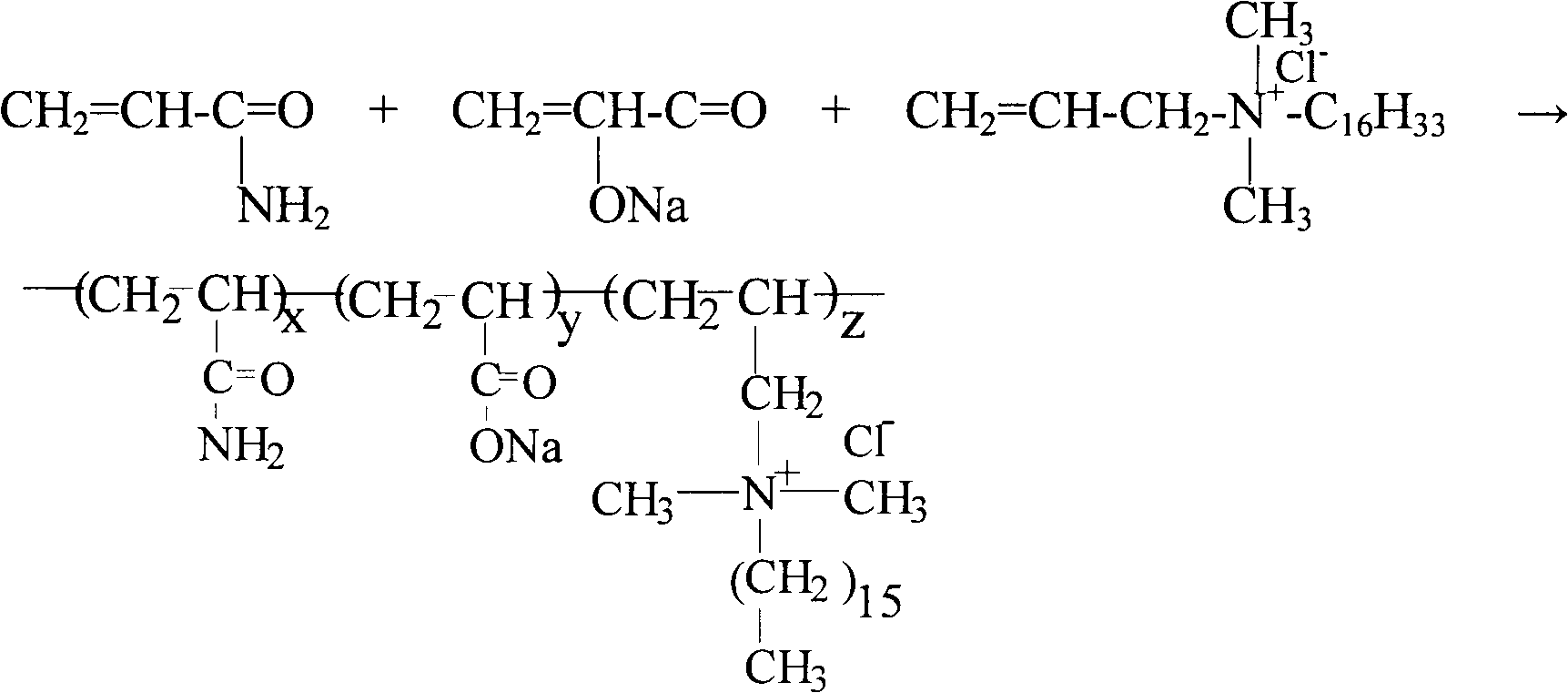

Embodiment 3

[0040] The weight percent of each monomer and water: AM:NaAA:C 12 DMAAC:H 2 O=25:6:1:68.

[0041] Solution preparation: Add 68g of distilled water into a 500mL beaker, add 25g of AMA monomer, add 6g of NaAA monomer, add C 12 DMAAC monomer 1g, adjust the pH to 7.5 with sodium bicarbonate, blow in nitrogen gas, stir and dissolve for 30 minutes, and adjust the temperature to 10±1°C.

[0042] Polymerization of the solution: In the above state, add the initiator ammonium persulfate, sodium bisulfite, and azobisisobutyronitrile totaling 1.5g, stop blowing nitrogen 30 minutes after initiation and seal the polymerization kettle, and put it in a heat-preserving and airtight condition at 45 degrees down until the end of heating.

[0043] Post-processing of the product: granulate the polymerized colloid, dry it, crush it into 20-40 mesh, and code it as G-3 for testing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com