A supported composite catalyst for producing high melt strength polypropylene

A high-melt strength, composite catalyst technology, applied in the field of polyolefin catalysts, can solve problems such as hindering long-chain branched structures, and achieve the effect of simplifying the preparation process and saving equipment investment and energy investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) The ZSM-5 molecular sieve material is used to prepare a carrier with an internal channel of 1.5 nm, a particle size of 5.0 μm, an external channel of 20 nm, and a thickness of 20 μm.

[0025] Activation of the carrier: 200 g of the carrier was taken, and dried at 200° C. for 2 hours under the protection of nitrogen flow, and then slowly raised to 600° C., and continued to dry for 4 hours to obtain a dehydrated carrier. The dehydrated carrier was dispersed in 5 L of hexane solvent, added with 0.14 mol of triethylaluminum, stirred at 30° C. for 2 hours, and then dried to obtain a treated carrier.

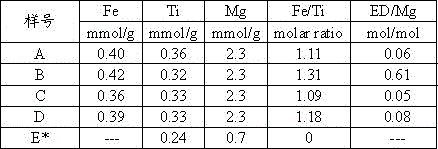

[0026] (2) Take 5mmol of iron acetylacetonate and 5mmol of bisiminopyridine ligand, and dissolve them in 100ml of toluene at room temperature. After they are completely dissolved, add 10g of the treatment carrier, raise the temperature to 50°C, and stir for 4h. Washed 3 times with toluene and dried under nitrogen blowing.

[0027] (3) Take 3.0g of magnesium dichloride, dis...

Embodiment 2

[0034] (1) Prepare a carrier with an inner channel of 1.5 nm, a particle size of 5.0 μm, an outer channel of 20 nm, and a thickness of 20 μm using diatomite material.

[0035] Activation of the carrier: 200 g of the carrier was taken, and dried at 200° C. for 2 hours under the protection of nitrogen flow, and then slowly raised to 600° C., and continued to dry for 4 hours to obtain a dehydrated carrier. Add 0.1 mol of triethylaluminum (for an alkylaluminum or alkylaluminum oxide) to the dehydration carrier in 5 L of hexane solvent dispersion, stir at 70° C. for 1 hour, and then dry to obtain a treated carrier.

[0036] (2) The obtained carrier is treated to reduce the loading amount of the late transition metal catalyst to prepare a composite catalyst. Compared with Example 1, the addition of iron acetylacetonate and bis-iminopyridine ligand is 2mmol, and the internal electron donor is ethyl benzoate, and other catalyst preparation conditions remain unchanged, the same as in E...

Embodiment 3

[0040] (1) A carrier with an inner channel of 1.2 nm, a particle size of 4.0 μm, an outer channel of 30 nm, and a thickness of 15 μm was prepared using montmorillonite materials.

[0041] Take 100 g of the carrier and dry it at 200° C. for 2 hours under the protection of nitrogen flow, then slowly raise the temperature to 600° C. and continue drying for 4 hours to obtain a dehydrated carrier. The dehydrated carrier was dispersed in 5 L of hexane solvent, added with 0.10 mol of triethylaluminum, stirred for 2 hours, and then dried to obtain a treated carrier.

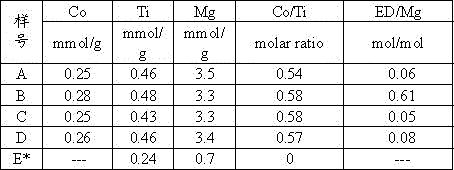

[0042] (2) Take 3mmol of cobaltous chloride and 3mmol of bis-iminopyridine ligand, and dissolve them in 100ml of toluene at room temperature. After they are completely dissolved, add 10g of the treatment carrier, raise the temperature to 50°C, and stir for 4h. Washed 3 times with toluene and dried under nitrogen purge.

[0043] (3) Take 5.2g of magnesium dibromide, dissolve it in 200ml of ether at 60°C, add 1.2ml of phe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com