Preparation method of triazine ramification inserting layer laminated clay heavy metal catching agent and application

A technology of heavy metal scavenger and triazine derivatives, which is applied in the direction of non-metallic elements, chemical instruments and methods, silicon compounds, etc., and can solve problems such as complex composition of treatment agents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0026] Preparation of Illite Intercalated with Mercapto-triazine Derivatives

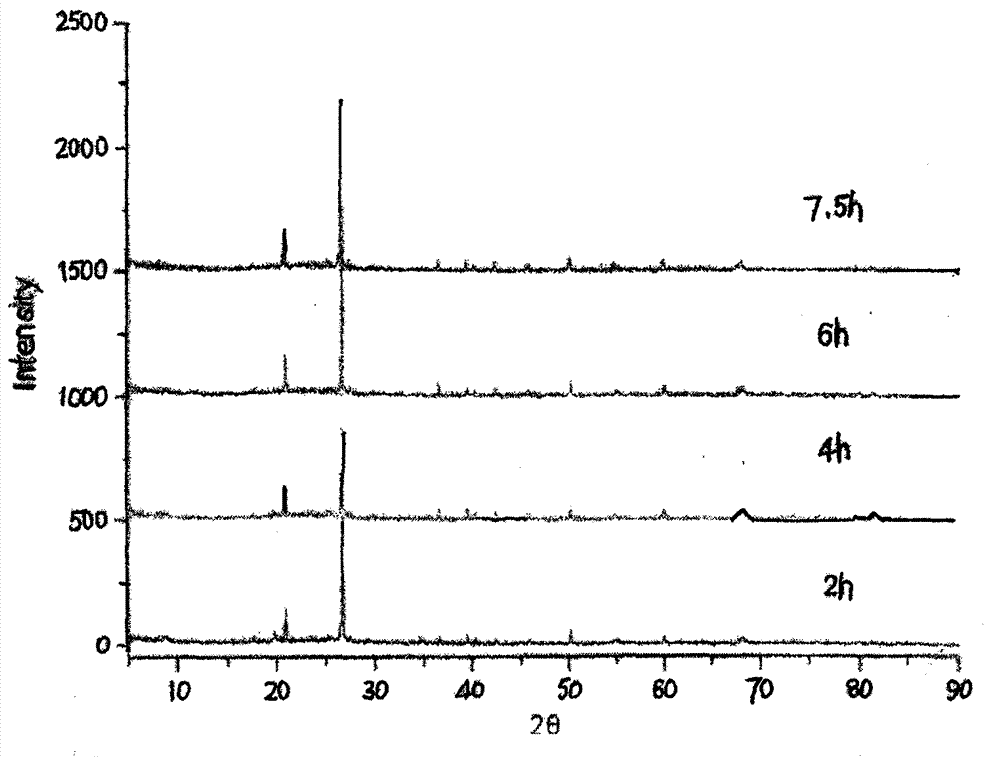

[0027] 1. Weigh 30g of 800 mesh illite powder, put it into a 250ml three-necked bottle with a stirring thermometer and a condenser, and add 40% sulfuric acid, sulfuric acid: water = 40:60 (W / W) 80g , heat up to 115°C, heat preservation reaction for 5 hours, filter and wash the filter cake until PH = 6, after drying, it can be seen from elemental analysis that the content of potassium in illite is reduced from 7.5% to 3.05%, and XRD diffraction analysis is done at the same time. It can be seen from the diffraction pattern that the illite crystal structure remains intact, but the interlayer spacing has increased significantly, as shown in figure 1 shown.

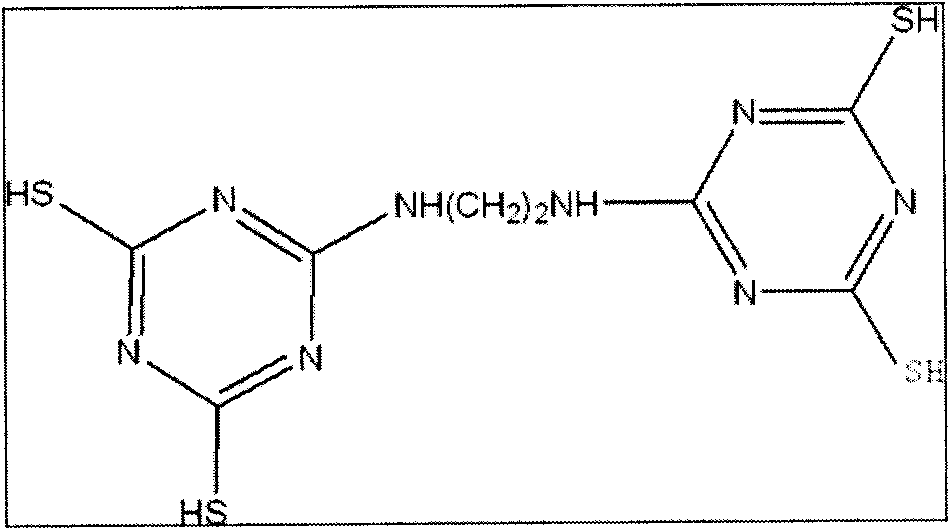

[0028] 2. Weigh 10g of the illite prepared above after potassium extraction, put it into a three-necked bottle with a stirring thermometer and a condenser, add 90ml of water, raise the temperature to 40°C under stirring, and slowly add 4.5g of ethy...

example 2

[0032] Application Experiment of Intercalation of Illite with Mercapto Triazine Derivatives

[0033] Prepare lead nitrate to contain lead 10ppm, 20ppm, 40ppm, 80ppm, 160ppm, take out 50ml each, add 0.5g of the mercaptoazine derivatives prepared above to intercalate illite, and adjust the pH to 8.5-9 at the same time. After fully stirring for 30 minutes, filter statically and detect with an ICP instrument. The result is that when the lead ion concentration is less than 80ppm, the lead concentration after treatment is less than the detection limit, and the detection value of 160ppm lead solution is 0.225ppm after treatment. Reached 97.18%.

example 3

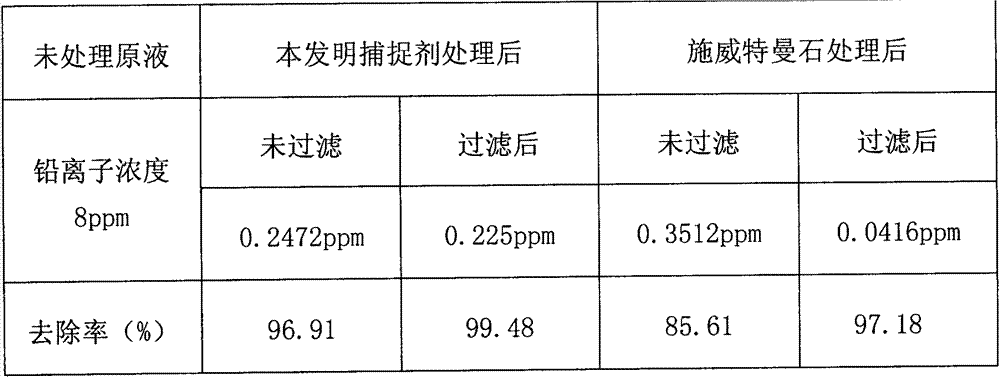

[0035] Comparative application of mercapto-triazine derivative intercalation illite and Schwittmannite

[0036] Take two prepared 50ml solutions with a lead ion concentration of 8ppm, add the mercaptotriazine derivative intercalation illite of the present invention and 0.5g of the commercially available Schwittmanite treatment agent respectively, and do a comparative experiment. After stirring for 30 minutes under the condition of pH=10, let it stand for 1 hour, filter and not filter respectively, and compare and detect. Test result table 1:

[0037] Table 1 The effect of thiolated triazine derivatives intercalating illite and Schwittmannite to remove lead ions

[0038]

[0039] From this table 1 find out that mercapto triazine derivative intercalation illite of the present invention does not filter effect and is obviously higher than unfiltered Schwittman stone treatment liquid, still higher than Schwittman stone treatment liquid after filtering, thus can It can be seen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com