Electrolyte membrane for all-solid-state lithium-ion battery and preparation method thereof

A lithium-ion battery and electrolyte membrane technology, which is applied in the field of all-solid-state lithium battery manufacturing, can solve the problem of low room temperature conductivity and achieve high room temperature conductivity, high lithium ion migration number, and good compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] a. Preparation of polymer electrolyte colloidal emulsion

[0038] First dissolve EVA in an organic solvent, add acrylonitrile monomer to the EVA solution and heat up to 70-80°C; then dropwise add the solution containing the initiator benzoyl peroxide to polymerize for 2-5 hours, add VEC to further Polymer colloid liquid is obtained after polymerization for 6-24 hours. An appropriate amount of lithium salt is ultrasonically dissolved in diethyl carbonate (DEC) or a mixed solution of DEC / EC, and the completely dissolved lithium salt solution is added to the polymer colloidal emulsion and stirred for 1-6 hours.

[0039] b. Preparation of composite polymer electrolyte emulsion modified by inorganic nanofillers

[0040] The polymer colloid liquid obtained in step a is mechanically stirred and mixed with the polymer colloid liquid of uniformly dispersed nano-inorganic fillers by ball milling for 2-8 hours to obtain a modified inorganic / organic composite electrolyte emulsion....

Embodiment 1

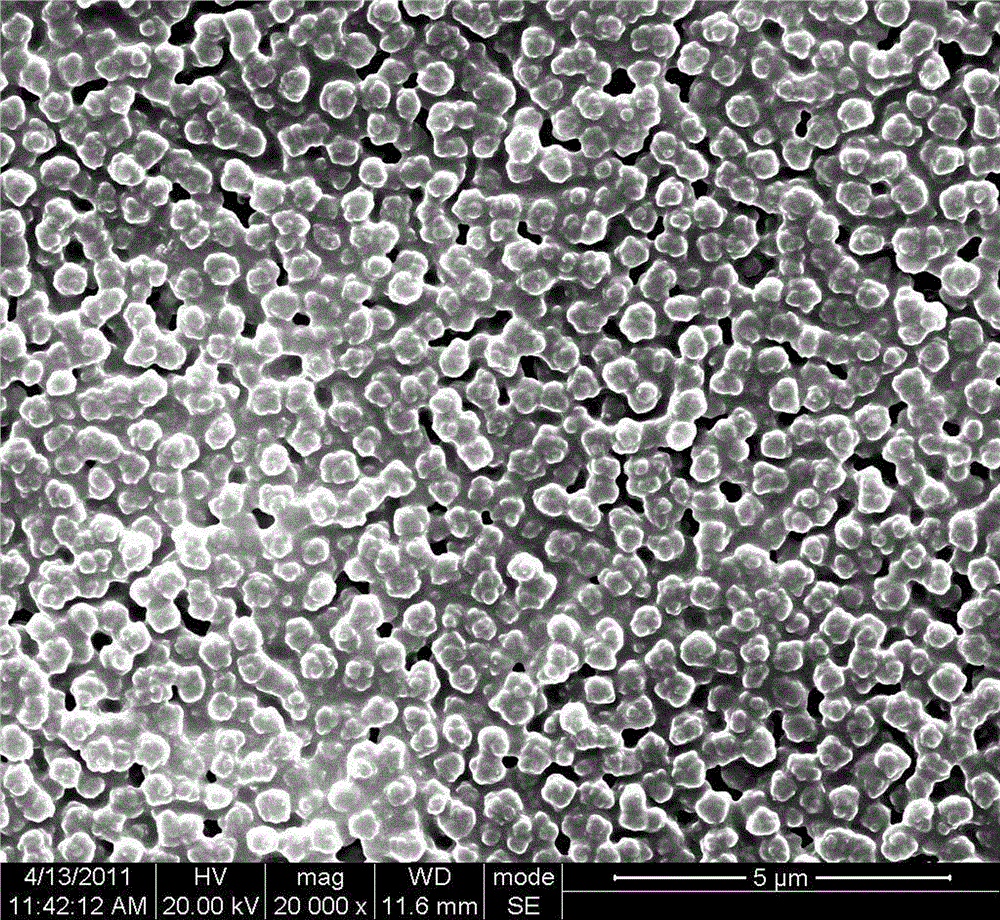

[0044] Add ethyl acetate and 1,4-dioxane organic mixed solvent (400g) and 23.4g ethylene-vinyl acetate copolymer (EVA, SumitateKC -10, 28wt% vinyl acetate), the mixture was heated to 70°C and completely dissolved in the solvent under mechanical stirring, then 93.6g of acrylonitrile (AN) monomer was added dropwise, and nitrogen gas was introduced for 30 minutes, and then The 30 mL toluene solution dissolved with 0.49 g of benzoyl peroxide was slowly added dropwise to the reaction system. After the dropwise addition, react for about 1 hour, and then add vinyl ethylene acetate (VEC, 46.8g) dropwise after the reactant turns into a light yellow emulsion. After 8 hours of reaction, P(AN -co- VEC) / EVA polymer emulsion. In this reaction system, the conversion rate of AN is above 85%, the solid content is about 20wt.%, the particle size of the polymer microspheres is 100-500nm, and the particle size of the latex is controlled by the polymerization reaction conditions. The obtained co...

Embodiment 2

[0047] Add ethyl acetate and 1,4-dioxane organic mixed solvent (400g) and 23.4g ethylene-vinyl acetate copolymer (EVA, SumitateKC -10, 28wt% vinyl acetate), the mixture was heated to 70°C and completely dissolved in the solvent under mechanical stirring, then 187.2g of acrylonitrile (AN) monomer was added dropwise, and nitrogen gas was introduced for 30 minutes, and then The 30 mL toluene solution dissolved with 0.49 g of benzoyl peroxide was slowly added dropwise to the reaction system. After the dropwise addition, react for about 1 hour, and then add vinyl ethylene acetate (VEC, 50.4g) dropwise after the reactant turns into a light yellow emulsion. After 8 hours of reaction, P(AN -co- VEC) / EVA polymer emulsion. In this reaction system, the conversion rate of AN is above 85%, the solid content is about 20wt.%, the particle size of the polymer microspheres is 100-200nm, and the particle size of the latex is controlled by the polymerization reaction conditions. The obtained c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com