In-situ double-axis tilting nanoindenter for transmission electron microscope

A nano-indenter and dual-axis tilting technology, which is applied in the use of radiation for material analysis, etc., can solve the problems of high design cost, limited application range, powerlessness, etc., and achieve reliable performance, expanded functions, and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

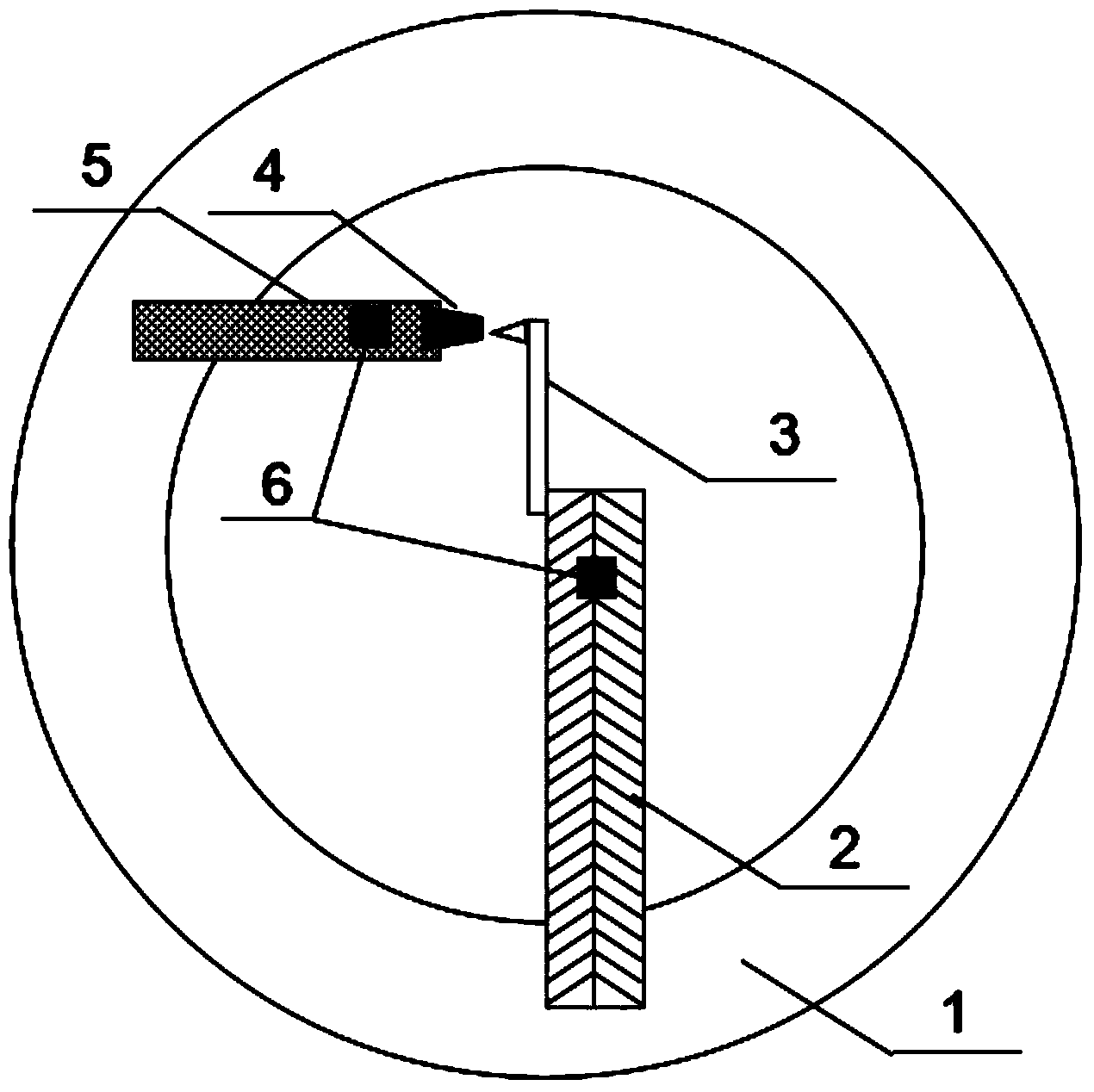

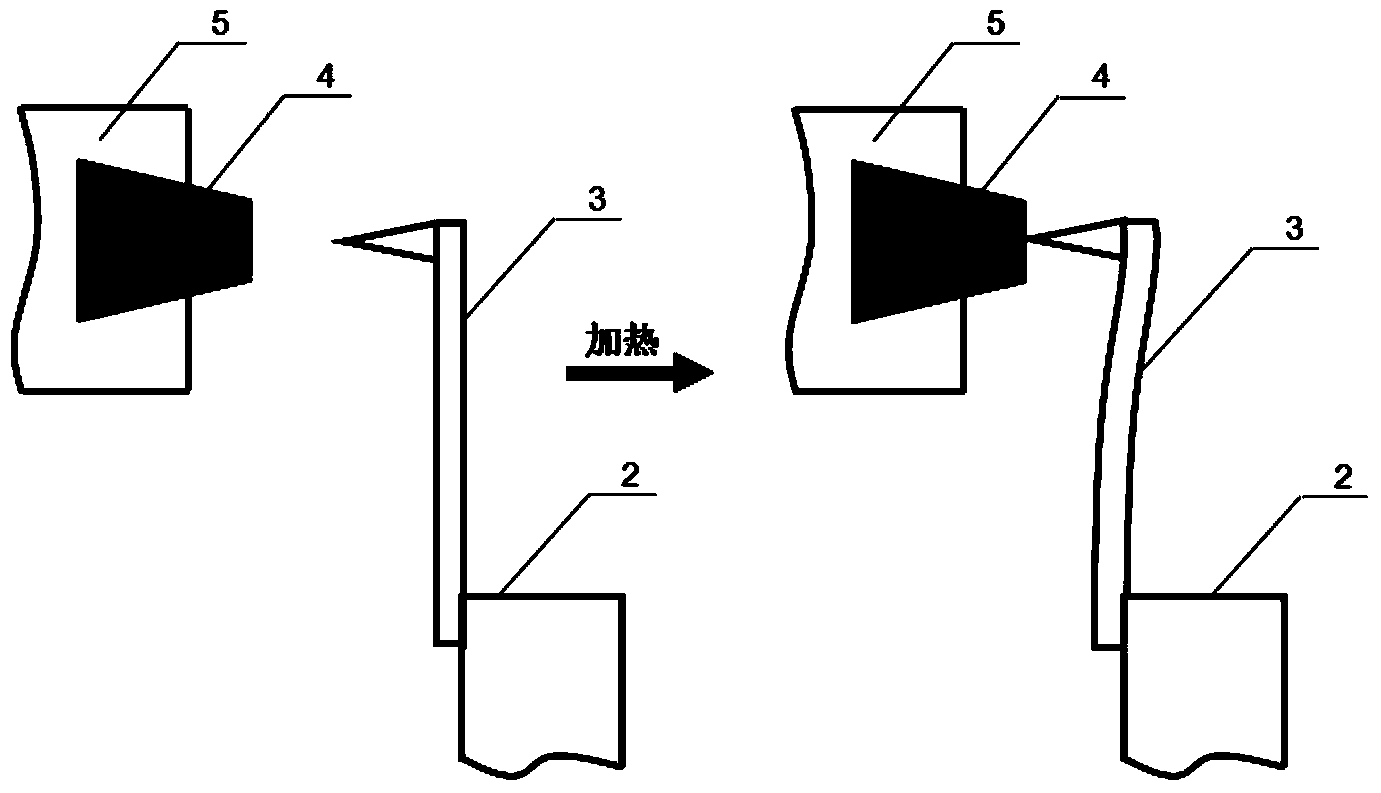

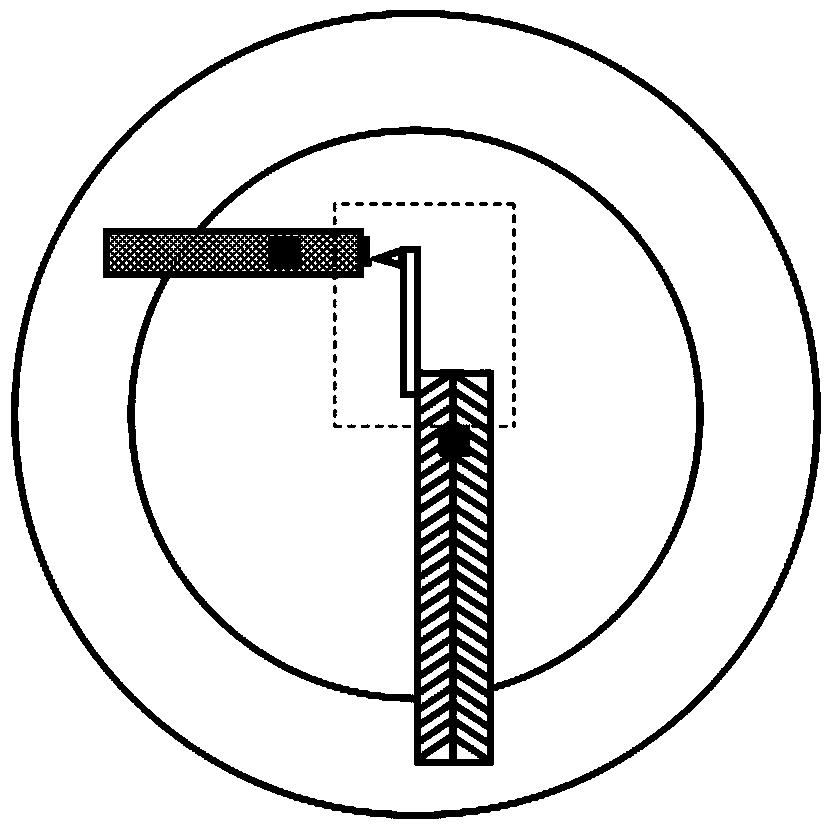

[0031] 1. Press figure 1 As shown, the thermal bimetal is made into a bimetal with a width of 0.2 mm, a thickness of 0.08 mm, and a length of 1.8 mm. At the same time, a Si cantilever needle tip with a length of 0.45 mm, a width of 0.2 mm, a thickness of 0.2 mm, and an elastic coefficient of 0.2 N / m is fixed on the side of the thermal bimetal sheet with a low expansion coefficient, and the unfixed cantilever on the thermal bimetal sheet One side of the beam needle tip is fixed on one side of a copper ring for transmission electron microscopy with an outer diameter of 3.0mm in the middle opening.

[0032] 2. Suspend one section of the thin area of the single crystal Si sample that has undergone mechanical grinding, electrolytic double spraying, and ion thinning, and fix the other end on the sample support platform. Under the optical microscope, fix the sample support platform on the 3mm copper ring, and make The sample is placed directly against the tip of the cantilever bea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com