An automatic pressure injection device and method for lubricating drag reducing mud for pipe jacking

An automatic, muddy technology, applied in pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of inability to precisely control the amount of grouting, poor grouting effect, high labor intensity, etc. The effect of slurry lubrication, preventing pipe collapse and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

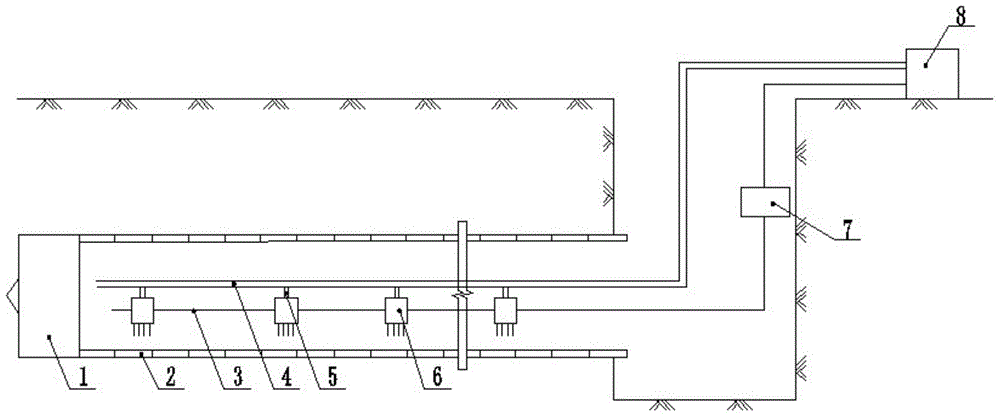

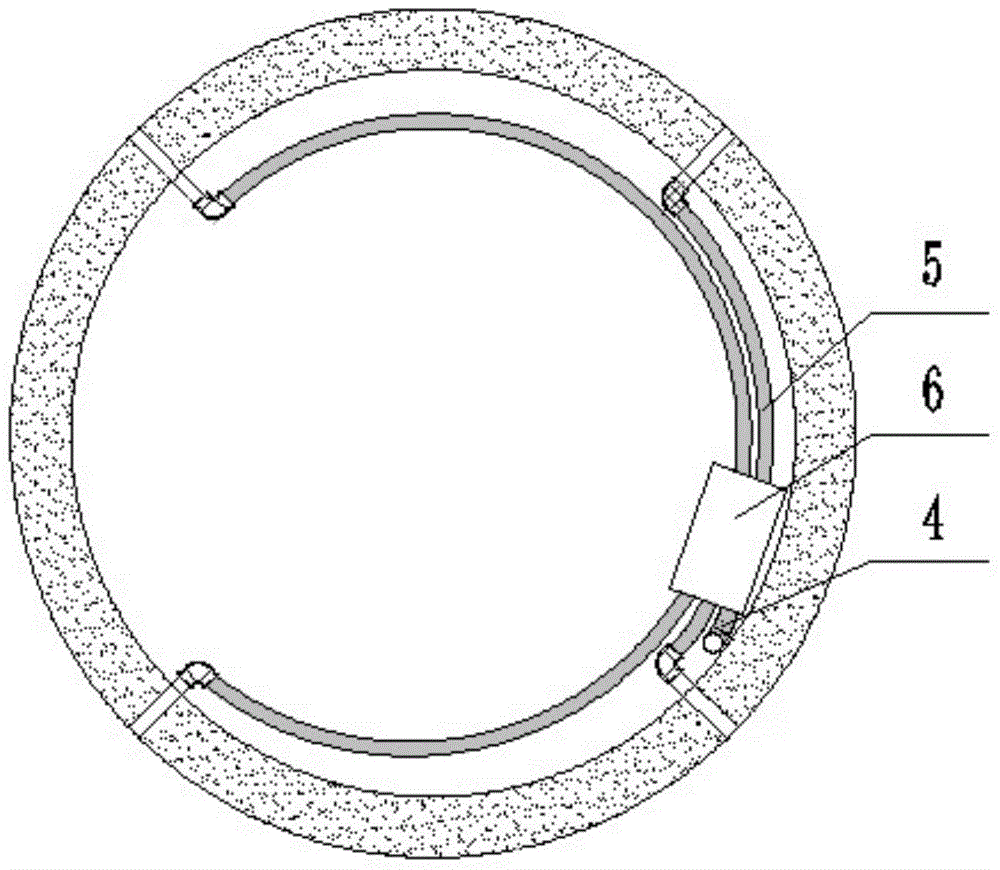

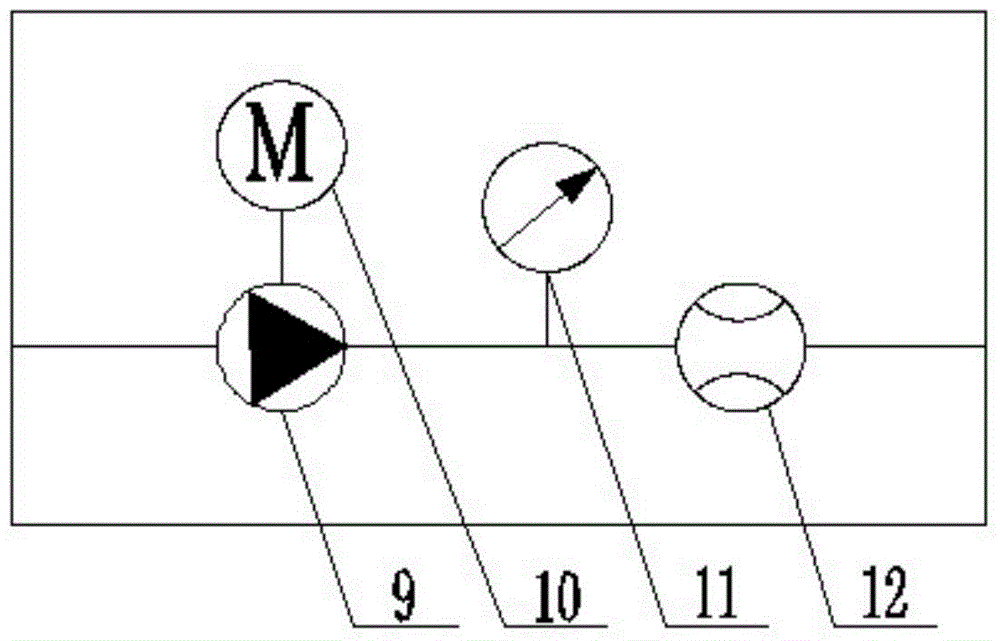

[0025] Such as figure 1 , figure 2 As shown, the automatic pressure injection device for lubricating and drag-reducing mud for pipe jacking of the present invention includes main parts such as control cables 3, main grouting pipes 4, sub-pipes for grouting 5, valve stations 6, centralized control boxes 7 and pumping stations, and the centralized control box 7 Control the pumping station and valve station 6 through the control cable 3, the grouting pump 9 sucks the drag-reducing mud and discharges it from the outlet of the pump, and then passes through the speed regulating motor 10, electromagnetic flowmeter 11, pressure sensor 12, The slurry main pipe 4 and the grouting branch pipe 5 are transported into the pipe, and the valve stations 6 are sequentially distributed in the jacking pipe. Corresponding grouting parameters on the grouting main pipe 4 and the grouting branch pipe 5 transmit data through the control cable 3, which is convenient for personnel to observe and recor...

Embodiment 2

[0030] The automatic pressure injection method of the lubricating and drag-reducing mud automatic pressure injection device for pipe jacking is adopted. The work of the valve station is the key to grouting. , install a valve station in the pipe every about 30m. During the jacking process of the whole line, the tail grouting is in the normally open state. Assuming that n valve stations are installed along the line, first open the n# valve station, every 4 The unit time is 5s ahead of the n-1# valve station. After continuing to jack up for 35m, assuming that it is opened to the m# (m<n), according to the installation of the n+1# valve station, open n+1#, and then open No. m# valve station, and so on, until the whole line runs through.

[0031] For the single-point valve station, the 0# main valve is in the normally open state, and then the 1# to 4# electric ball valves are opened in turn, and the 2# electric ball valve is opened 5 seconds before the 1# electric ball valve is clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com