One-time paving forming method of polymer modified cement concrete

A technology of cement concrete and molding method, which can be applied to cohesive pavement paved on site, roads, and road repairs, etc., which can solve problems such as complex processes, achieve the effects of simplifying construction processes, improving construction quality, and reducing construction operation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

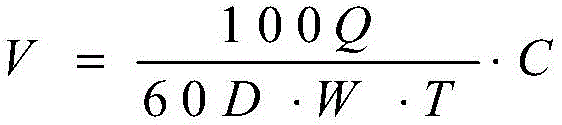

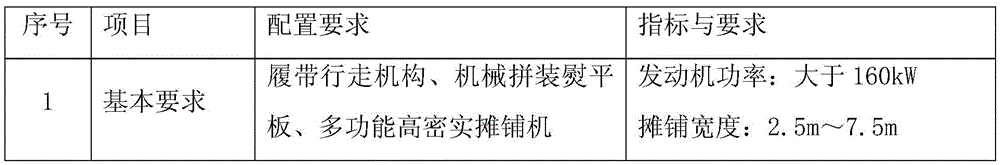

[0029] The polymer-modified cement concrete one-time paving forming method of the present invention adopts an asphalt paver with a high-density screed structure, and through the setting of operating parameters and corresponding construction techniques, the thin layer (<40mm) of polymer modified The high-strength cement concrete is paved and formed at one time, without the need for subsequent vibratory rolling by road rollers or subsequent vibratory compaction with vibrating bars, and the polymer modified concrete can reach the specified compactness. In order to make the polymer-modified concrete reach the specified density, the structure, system configuration and adjustable range of working parameters of the paving equipment working device meet the requirements in Table 1.

[0030] Table 1 Working device structure, system configuration and parameter range

[0031]

[0032]

[0033]

[0034] In order to make the polymer-modified concrete reach the specified compactness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com