Combined rubber gasket material and preparation method thereof

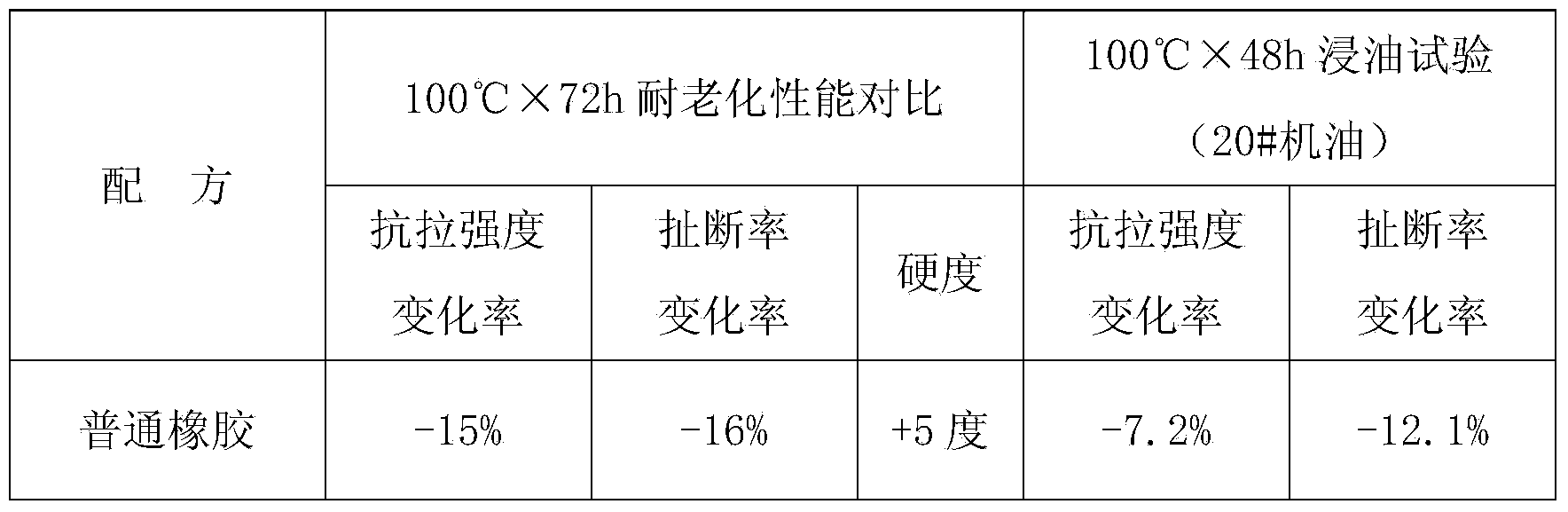

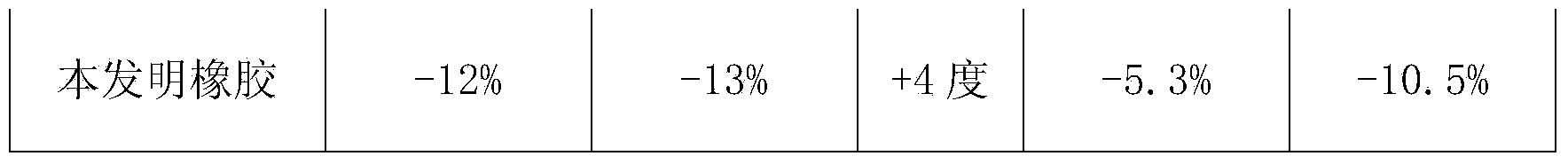

A technology of rubber gasket and butyl rubber, which is applied in the field of combined rubber gasket material and its preparation, can solve the problems of low strength, poor wear resistance, unsatisfactory sealing effect, etc., achieve good thermal stability and oil resistance, improve Process performance, the effect of reducing toxic and side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in detail below through specific examples.

[0010] A combined rubber gasket material, made of the following raw materials in parts by weight (kg): butyl rubber (CBK139) 70, nitrile rubber 10, natural rubber 6, sulfur 1, polydimethylsiloxane 3, phenol 1. Zinc acetate 8, dibutyl maleate 6, isooctyl dithioglycolate di-n-octyl tin 1, zinc oxide 3, cork powder 10, N550 carbon black 24, modified attapulgite 10;

[0011] The modified attapulgite is made of the following raw materials in parts by weight (kg): attapulgite 20, toluene diisocyanate 3, trimethylolpropane triacrylate 2, medical stone 30, ascorbic acid 1, jade 2, Polyisobutylene 2, aluminate coupling agent DL-4111, Zanthoxylum bungeanum seed oil 1; the preparation method is to mix attapulgite, medical stone, and jade into a calciner and calcinate at 700-720°C for 3-4 hours, Cool, soak in 10-12% hydrochloric acid solution for 1-2 hours, filter and take out, wash with water and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com