Method for preparing water-soluble chitosan oligosaccharide by adopting ultrafiltration and nanofiltration

A technology of water-soluble chitosan oligosaccharides and chitosan oligosaccharides, applied in chemical instruments and methods, preparation of sugar derivatives, amino sugars, etc., can solve the problems of complex hydration process and high cost, and achieve simple degradation method, low cost, and improved The effect of degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

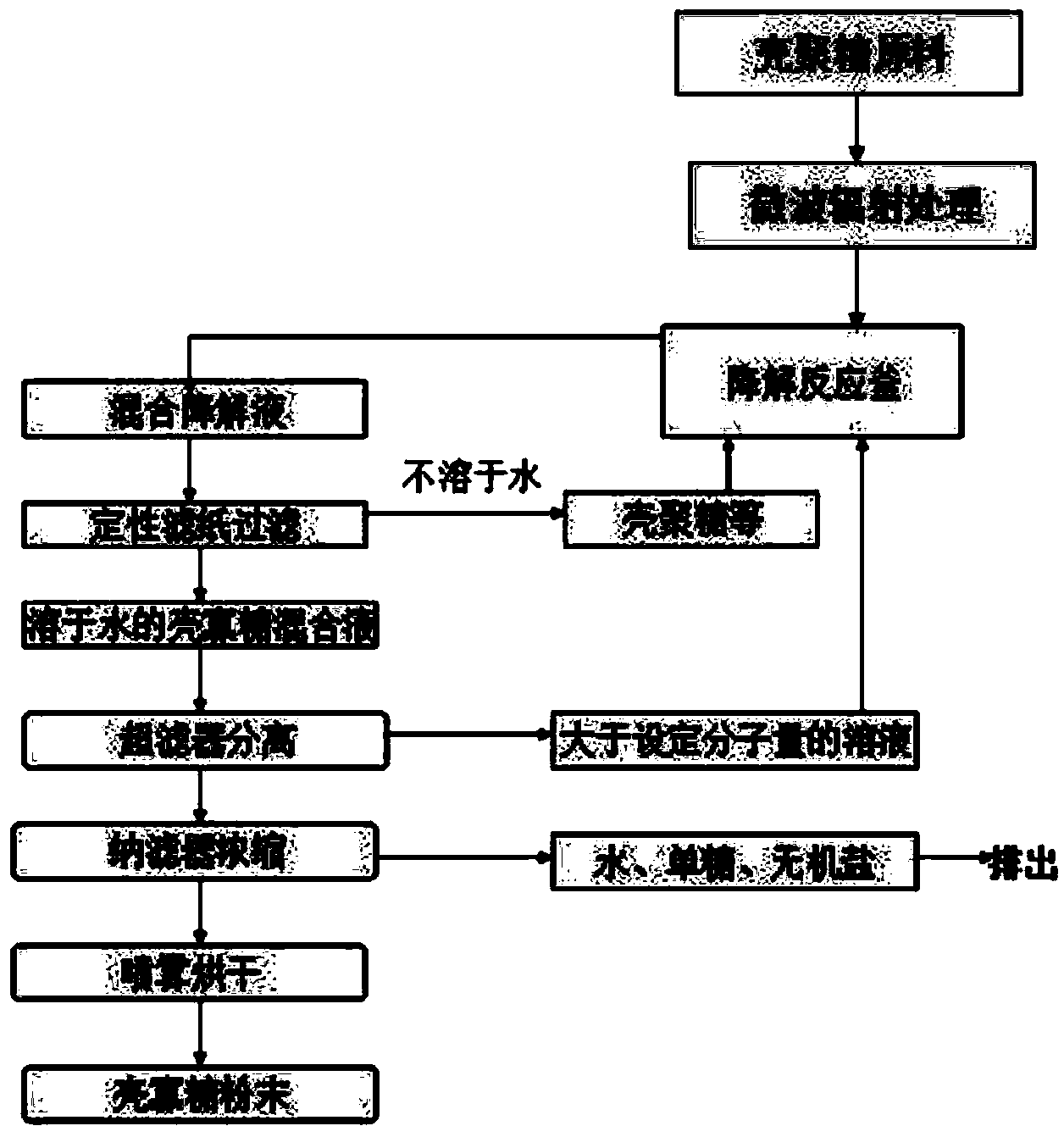

[0055] 1. After rinsing and drying, 10 kg of chitosan raw materials are put into a special microwave reactor for microwave radiation treatment, the microwave power is 1000W, the temperature is controlled at 60°C, and the reaction time is 1 hour.

[0056] 2. Add 35 liters of water to the reaction vessel and heat the water to 40°C; then add 10 kg of chitosan treated with microwave radiation into the vessel, stir evenly, and make the raw materials evenly infiltrated.

[0057] 3. Add 15,000 ml of hydrogen peroxide (35% by mass) solution to the chitosan infiltration solution in 4-5 times, stir while adding, and mix well. The degradation reaction of chitosan begins, and the material slowly rises accordingly. During the degradation process, the temperature is controlled within 80°C. After the reaction has proceeded for 4 hours, the degradation is complete, and it is cooled to normal temperature. Use qualitative filter paper to filter under negative pressure to separate the undegraded chi...

Embodiment 2

[0067] 1. After rinsing and drying, 10 kg of chitosan raw materials are put into a special microwave reactor for microwave radiation treatment, the microwave power is 1000W, the temperature is controlled at 60°C, and the reaction time is 1 hour.

[0068] 2. Add 35 liters of water to the reaction vessel and heat the water to 40°C; then add 10 kg of chitosan treated with microwave radiation into the vessel, stir evenly, and make the raw materials evenly infiltrated.

[0069] 3. Add 15,000 ml of hydrogen peroxide (50% by mass) solution to the chitosan infiltration solution in 4-5 times, stir while adding, and mix well. The degradation reaction of chitosan begins, and the material slowly rises accordingly. During the degradation process, the temperature is controlled within 80°C. After the reaction was carried out for 3 hours, the degradation was over, and it was cooled to normal temperature. Use qualitative filter paper to filter under negative pressure to separate the undegraded chi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com