Method of economically recycling phosphor from excess sludge

An economical technology for excess sludge, applied in the field of water treatment, can solve the problems of high cost of phosphorus, and achieve the effect of stabilization and reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

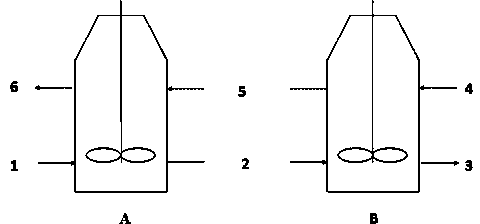

Image

Examples

Embodiment 1

[0037] (2) To the alkali hydrolysis sludge, directly inject X volume of excess sludge with a concentration of 20 g / L into the reactor with a pH condition of 13.0 in step (1) to mix, and continue stirring for 1 hour to reduce the pH to 9.6 . Then centrifuge solid-liquid separation at 4000 rpm, collect the supernatant, and measure the concentrations of orthophosphate and ammonia nitrogen in the supernatant to be 70 mg / L and 65.5 mg / L, respectively. At this time, the residual TSS and VSS after centrifugation were reduced by 40% and 55% compared with the remaining sludge, which achieved a stabilization effect and was conducive to subsequent treatment and disposal.

[0038] (3) According to the molar concentration and content of orthophosphate in the supernatant, add magnesium salt with a Mg / P molar ratio of 1.4, stir and react at 100 rpm for 10 minutes until a large amount of precipitation occurs, and separate the precipitate by gravity or centrifugation. Dry naturally to obtain ...

Embodiment 2

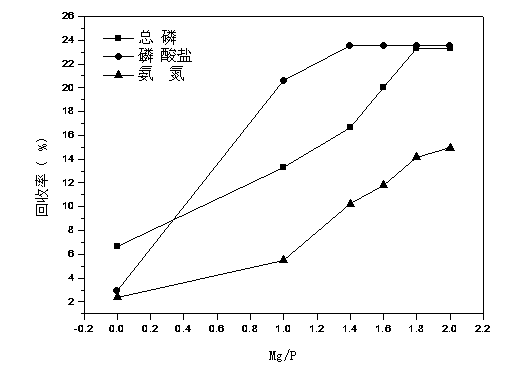

[0043] (2) Measure the concentration of orthophosphate in the effluent 6. According to its molar concentration, add 0, 1.0, 1.4, 1.6, 1.8 and 2.0 times the molar number of magnesium salt to it, and stir at 100 rpm for 10 minutes until it appears A large amount of precipitation, gravity or centrifugation to separate the precipitate, and natural drying to obtain the crude product of magnesium ammonium phosphate. Depend on image 3 It can be seen that the amount of magnesium salt added is within the range of 0-1.4 times the molar concentration of orthophosphate, and with the increase of the amount of magnesium added, more phosphorus and nitrogen elements in the effluent are recovered to generate magnesium ammonium phosphate products; But after 1.4 times, the recovery rate of phosphorus element (orthophosphate) remains unchanged, and there is no longer magnesium ammonium phosphate, so the more suitable magnesium input amount (Mg / P ratio) is 1.4. At the same time, the concentratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com