Method for carrying out organic wastewater pretreatment by using an iron-carbon-Fenton-integrated reactor

A technology of organic wastewater and reactors, applied in chemical instruments and methods, oxidized water/sewage treatment, water/sewage treatment, etc., can solve the problems of poor biodegradability and large amount of chemical sludge, and achieve the goal of improving biochemical ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

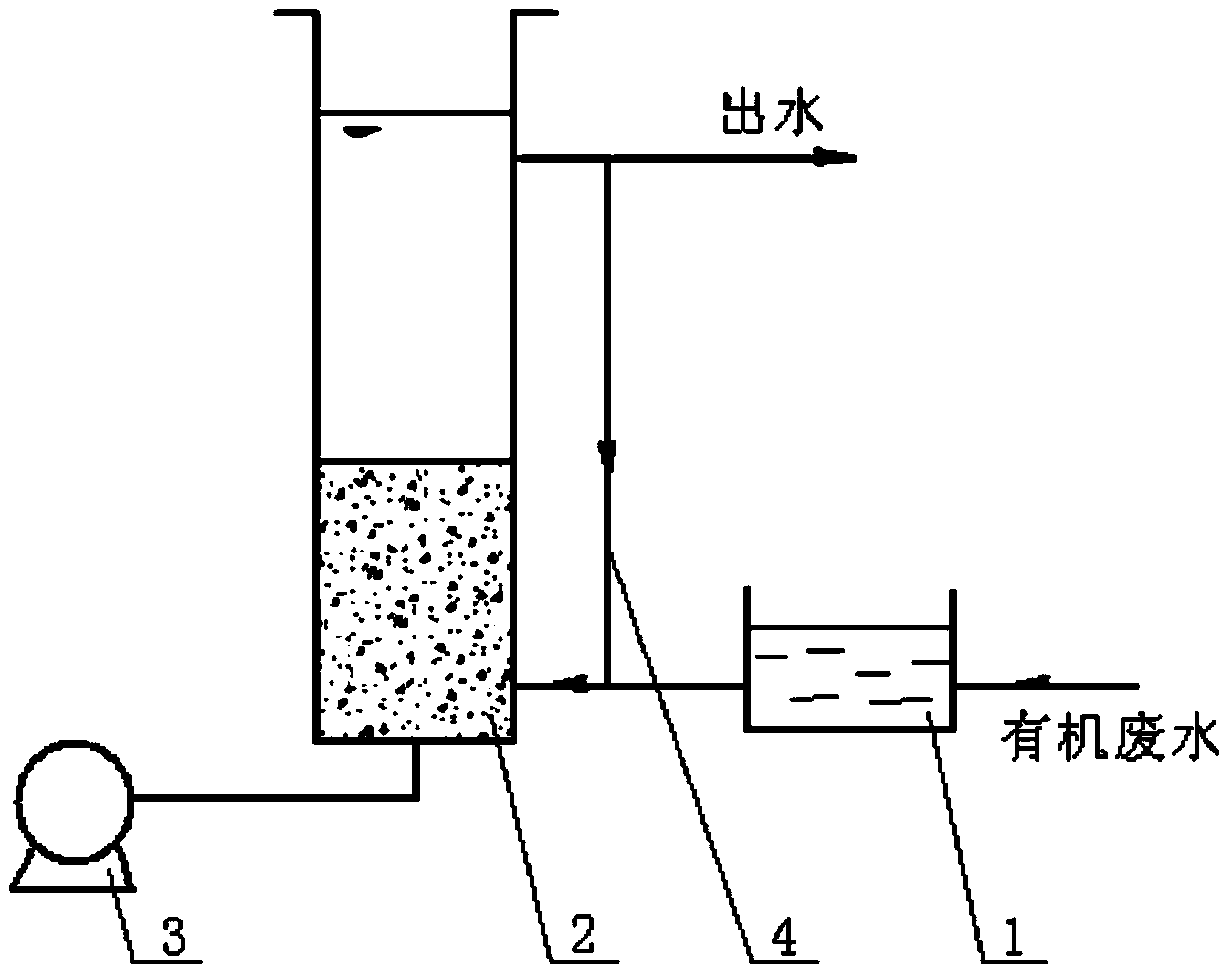

[0017] Specific embodiment one: the method for utilizing the iron-carbon-Fenton integrated reactor of the present embodiment to carry out organic wastewater pretreatment is carried out according to the following steps:

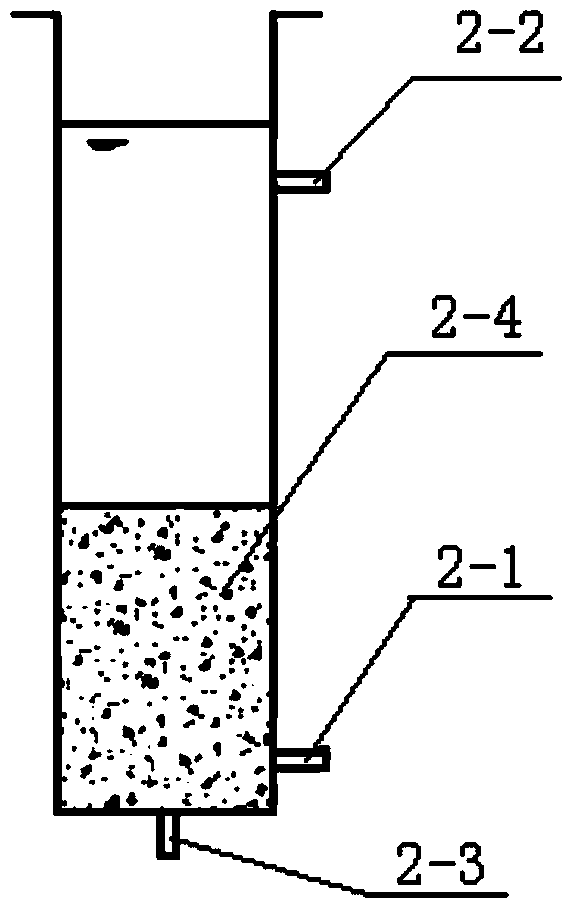

[0018] 1. Iron-carbon-Fenton integrated reactor system: Iron-carbon-Fenton integrated reactor system is composed of pH adjustment pool 1, iron-carbon-Fenton integrated reactor 2, fan 3 and return pipe 4;

[0019] The lower part of the side wall of the iron-carbon-Fenton integrated reactor 2 is provided with a water inlet 2-1, the upper part of the side wall is provided with a water outlet 2-2, and the bottom is provided with an air inlet 2-3; in the iron-carbon-Fenton integrated reactor 2 Filled with iron carbon filler 2-4;

[0020] The pH adjustment pool 1 is connected to the water inlet 2-1 of the iron-carbon-Fenton integrated reactor 2, and the fan 3 is connected to the air inlet 2-3 of the iron-carbon-Fenton integrated reactor 2; A return pipe 4 is provid...

specific Embodiment approach 2

[0022] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the iron-carbon filler is a mixture of elemental iron and charcoal, and the mass ratio of elemental iron and charcoal is (0.8-5.0): 1; other and specific implementation Method 1 is the same.

specific Embodiment approach 3

[0023] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the elemental iron is iron balls or iron flakes. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com