Spring grinding machine

A technology of spring grinding machine and motor pump, which is applied in the field of grinding spring machinery and spring grinding machine, which can solve the problems of damage to parts, increase the space occupation of the production site, and have a good cooling effect, so as to prevent damage to parts and reduce the size of the machine. The effect of equipment occupying space and avoiding stability degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

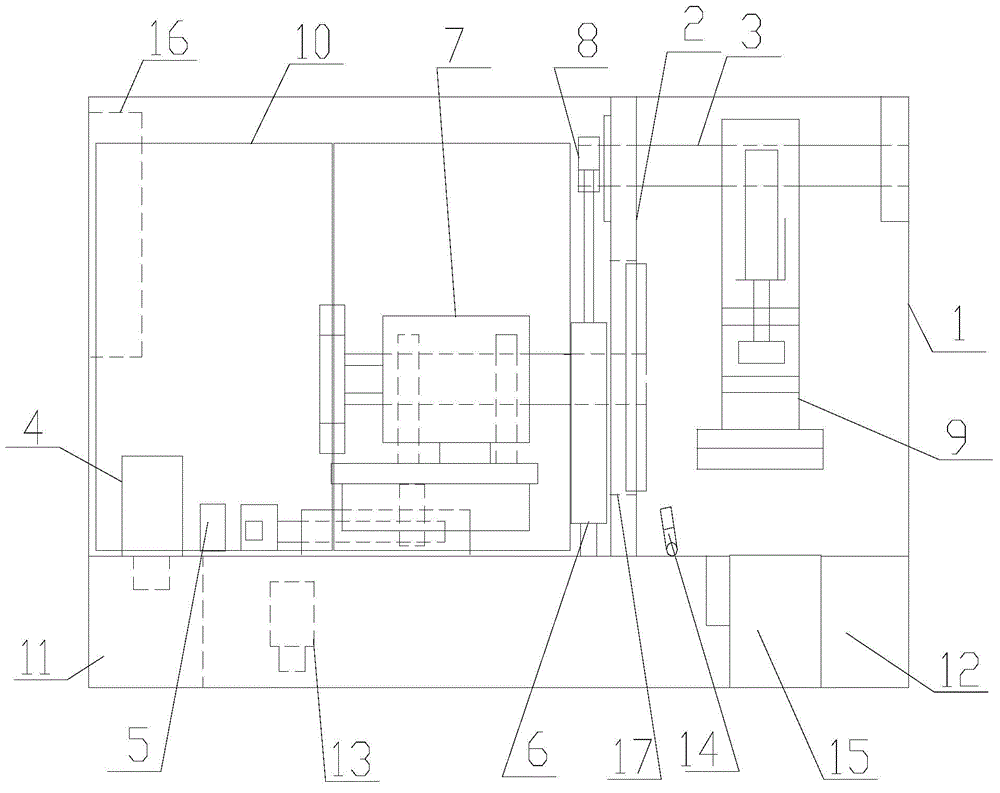

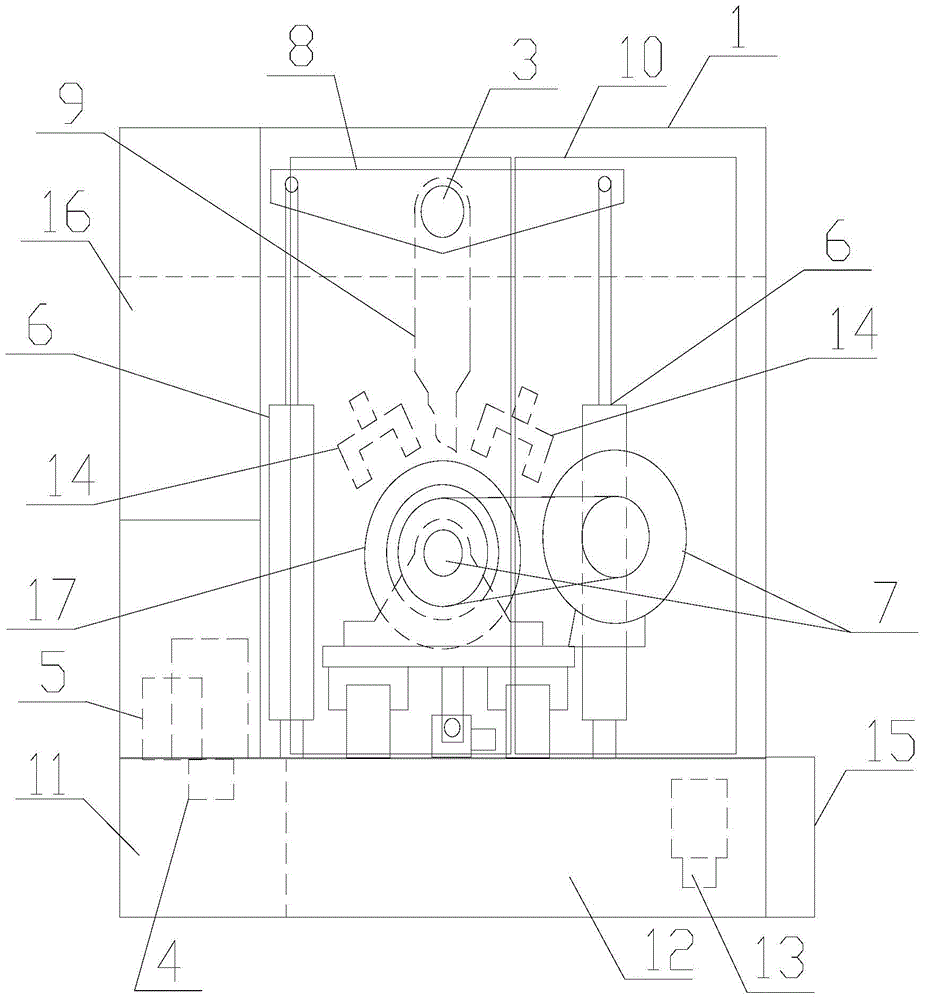

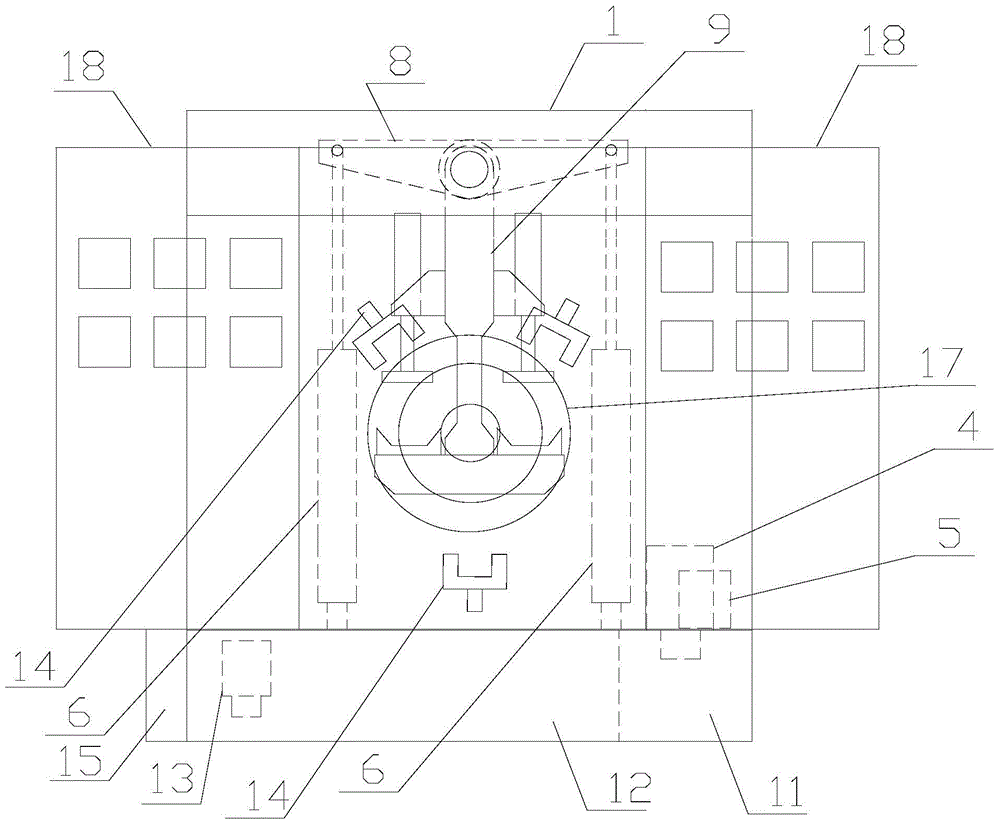

[0030] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 , a spring grinding machine of the present invention, comprising a first frame body 1, a partition plate 2, a connecting shaft 3, a first motor pump group 4, a valve group 5, a first hydraulic cylinder 6, a grinder device 7, a connecting arm 8, Support seat 9, protective door 10, oil tank 11, water tank 12, second motor pump group 13, water spray port 14, wear debris separation device 15, electrical box 16 and through hole 17, the input of the first motor pump group 4 The output end of the first motor pump group 4 is connected to the input end of the valve group 5, the output end of the valve group 5 is connected to the first hydraulic cylinder 6, and the input end of the second motor pump group 13 connected to the water tank 12, the output end of the second motor pump unit 13 is connected to the water spray port 14, the first frame body 1 is supported on the oil tank 11 and the water ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com