Production method and application of cobaltous oxide/carbon nanostructure array

A technology of carbon nanostructure and cobalt monoxide, which is applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., to achieve the effects of low reaction temperature, high power density and energy density, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A preparation method of cobalt monoxide / carbon nanostructure array, the steps are as follows:

[0034] 1. Prepare 50mL of a mixed aqueous solution containing 0.05M cobalt nitrate hexahydrate and 0.23M urea, stir at room temperature for more than 10 minutes to obtain a uniform red solution, and then transfer the solution to the liner of a stainless steel reactor lined with polytetrafluoroethylene. At the same time, immerse the cleaned nickel mesh (20×50×1.1mm 3 ,110PPI,353g / m 2 , Shenzhen Kejing) substrate, sealed, reacted at 95 ° C for 8 hours, the volume ratio of the aqueous solution to the reactor was 50:90. After the reaction, take out the base of the nickel mesh and rinse it several times with water to clean the residual reaction substances attached to the surface. At this time, the color of the nickel mesh changes from silvery white to purple red due to the growth of the cobalt monoxide precursor. Dry the cleaned nickel mesh with the precursor at 60°C and put it ...

Embodiment 2

[0039] A preparation method of cobalt monoxide / carbon nanostructure array:

[0040] According to the conditions of step 1 of Example 1, after annealing at 427°C for 3 hours, acetylene gas was introduced, the flow rate was controlled at 6 sccm, and the ventilation time was 150 seconds, and then the annealing was continued for 0.5 hours, the temperature was kept at 427°C, and then cooled naturally , take out the nickel mesh, and the nitrogen flow rate remains constant at 80 sccm throughout the process. The cobalt monoxide / carbon nanowire array can be obtained, and its topography is shown in Fig. 2(b).

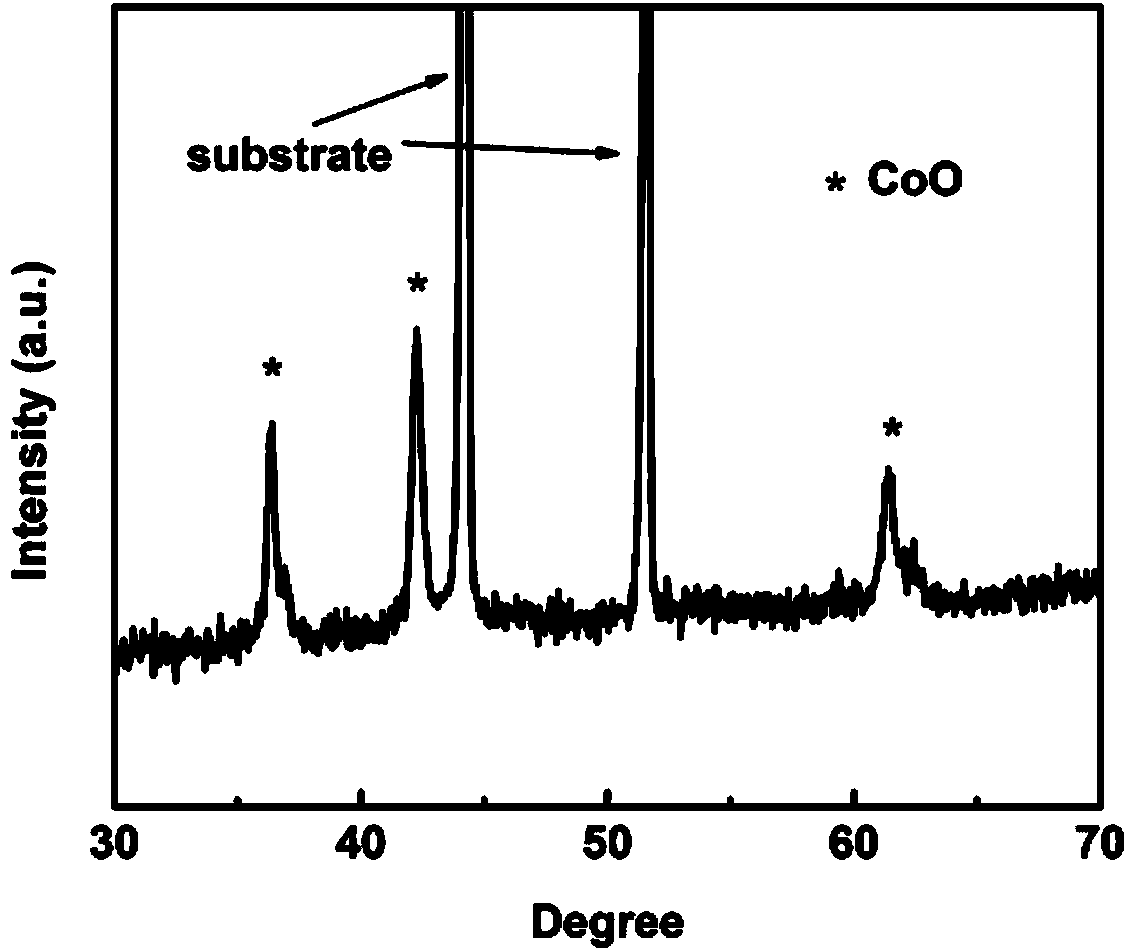

[0041] Analytical tests show that when the ventilation time is increased to 150s, a layer of carbon layer grows on the surface of cobalt oxide, as shown by the transmission electron microscope ( Figure 4 ) It can be seen that there is a layer of carbon layer with good crystallinity on the surface of cobalt oxide, whose lattice constant coincides with the (002) plane of graphite...

Embodiment 3

[0043] A preparation method of cobalt monoxide / carbon nanostructure array:

[0044] According to the conditions of Step 1 of Example 1, the concentration of 0.23M urea in the hydrothermal process was changed to 0.2M, and the rest of the process and conditions were the same as in Example 2.

[0045] After annealing at 427°C for 3 hours, cobalt oxide cluster arrays can be obtained before acetylene gas is introduced, and finally cobalt oxide / carbon nano cluster arrays are obtained.

[0046] Analytical tests showed that when the ventilation time was 150s, the surface morphology of cobalt monoxide changed ( Figure 2c ), the cluster array becomes more porous and the surface is covered with a layer of carbon, indicating that this morphology can also deposit carbon. The material was placed in a 6M KOH solution as a working electrode, and measured in a three-electrode system, the reference electrode was a saturated calomel electrode, and the platinum wire electrode was a counter elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com