Multi-scale capillary core flat plate loop heat pipe type heat-dissipation device

A flat-plate loop and cooling device technology, which is applied to circuits, indirect heat exchangers, lighting and heating equipment, etc., can solve problems such as difficulty in starting loop heat pipes, low limit heat dissipation capacity, and difficulty in starting at low temperatures, so as to improve limit heat dissipation ability, solve the difficulty of starting at low temperature, and improve the effect of anti-gravity performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention provides a multi-scale capillary core flat plate loop heat pipe heat dissipation device. The present invention will be further described below in conjunction with the accompanying drawings and specific implementation methods.

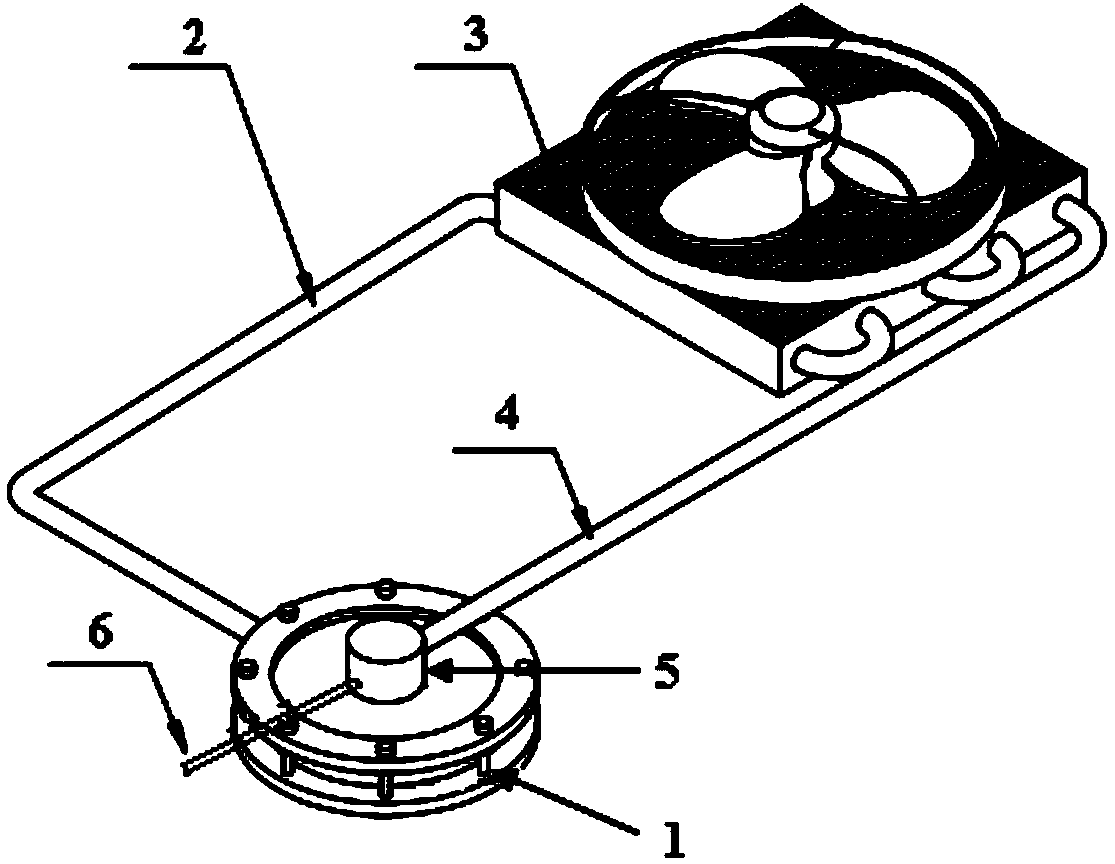

[0029] Such as figure 1 As shown, the heat dissipation device includes an evaporating part 1, a condensing part 3, a compensation chamber 5 processed together with the evaporating part cover plate 12, and a gas phase pipeline 2 connecting the evaporating part 1 and the condensing part 3, connecting the condensing part 3 and the compensation chamber The liquid phase pipeline 4 of 5, the vacuumizing and working fluid filling pipeline 6 connected with the compensation chamber 5.

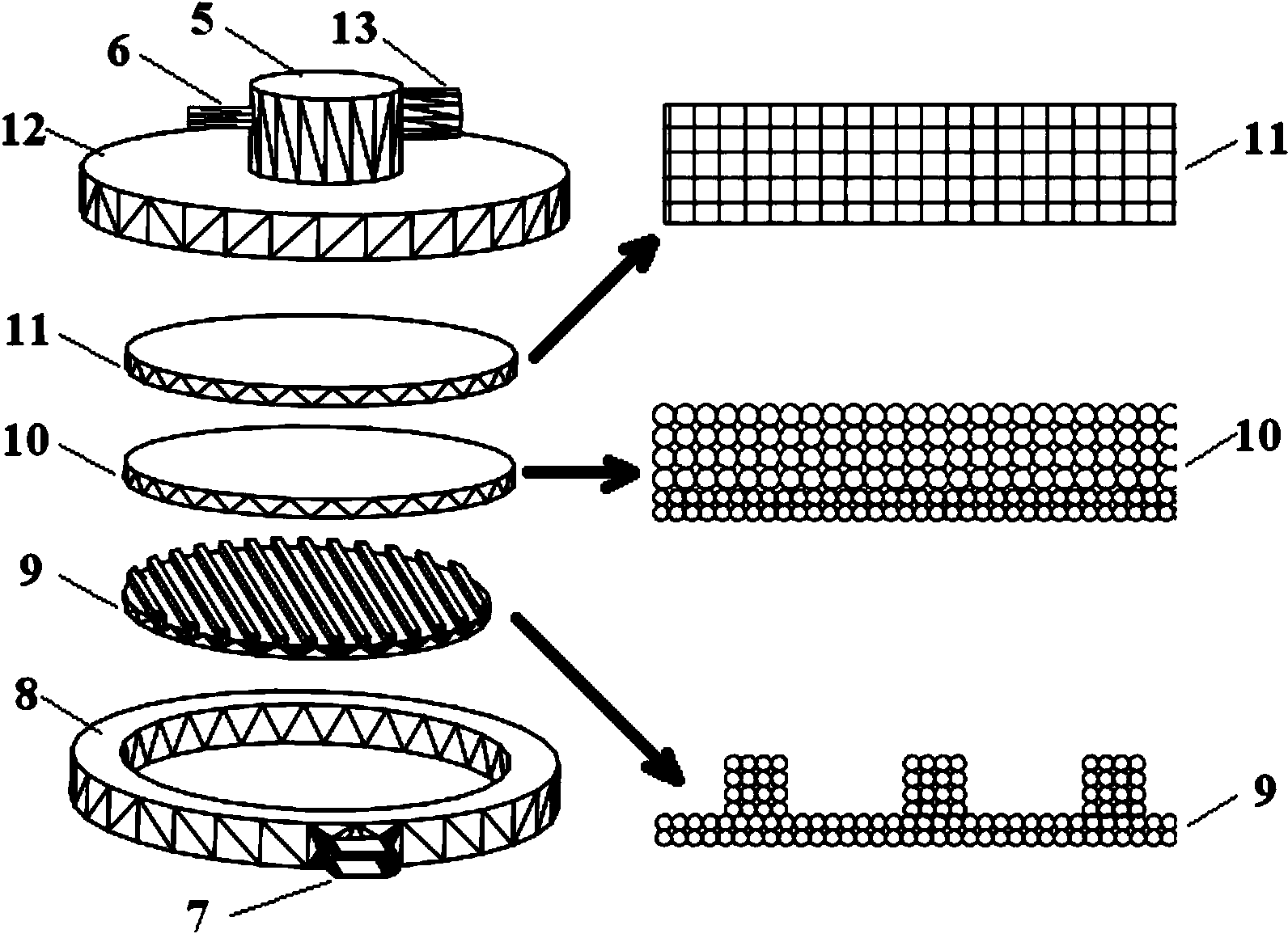

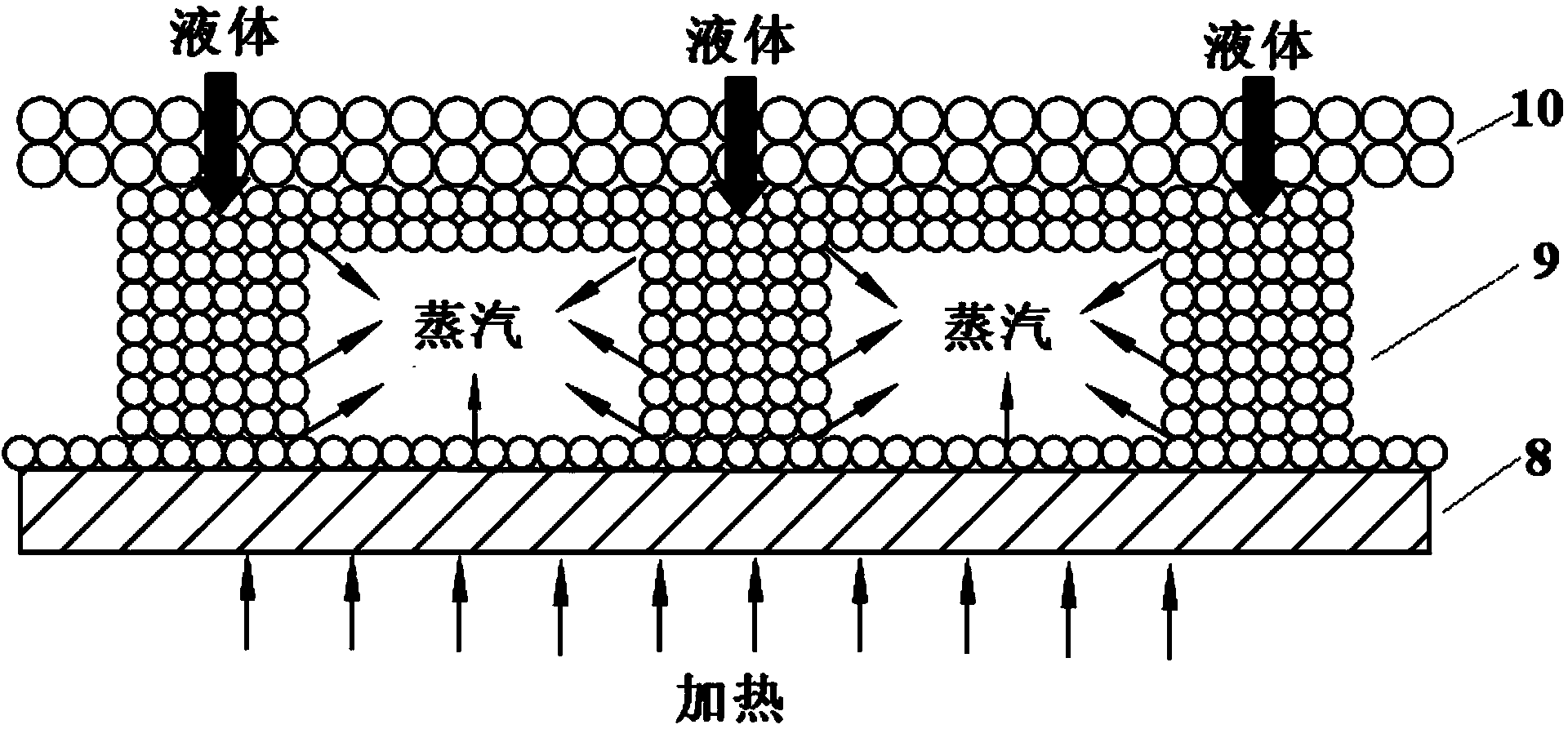

[0030] The key technology of the loop heat pipe type cooling device lies in the internal design and manufacture of the flat plate evaporator. Such as figure 2 As shown, the base plate 8 at the bottom of the evaporation part 1 is in the shape of a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com