A method for preparing calcium-doped rebco high temperature superconducting quasi-single crystal

A high-temperature superconducting, single crystal technology, applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of other elements pollution, slow growth rate, dependence on the pulling method, etc., the method is simple, easy to operate, easy to The effect of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

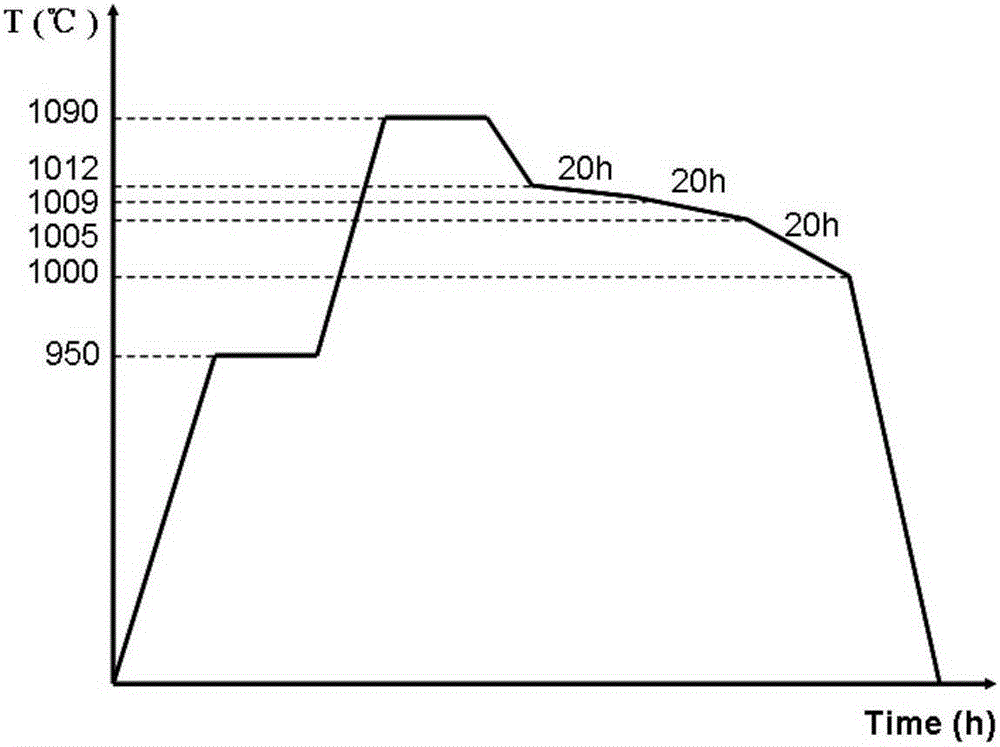

[0035] In this example, if figure 1 and figure 2 As shown, in the top seed melt texture method, the schematic diagram of the placement of seed crystal 1 and precursor 2 in the growth furnace, and the schematic diagram of the temperature program of seed crystal 1 and precursor 2 for the growth of the molten structure are respectively given. Specifically, a method for preparing a calcium-doped YBCO high-temperature superconducting quasi-single crystal in this embodiment includes the following steps:

[0036] 1. According to the ratio of Y:Ba:Cu=1:2:3, Y 2 o 3 、BaCO 3 Mix with CuO powder to obtain Y123 phase powder.

[0037] 2. After fully grinding the Y123 phase powder in step 1, sintering in air at 900°C for 48 hours, grinding the sintered powder again, and sintering in air at 900°C for 48 hours, repeating three times to obtain Y123 with uniform and single composition Pure phase powder.

[0038] 3. The Y123 pure phase powder obtained in step 2, CaCO 3 Powder, CeO 2 Pow...

Embodiment 2

[0050] A method for preparing a calcium-doped YBCO high-temperature superconducting quasi-single crystal, comprising the following steps:

[0051] 1. According to the ratio of Y:Ba:Cu=1:2:3, Y 2 o 3 、BaCO 3 Mix with CuO powder to obtain Y123 phase powder.

[0052] 2. After fully grinding the Y123 phase powder in step 1, sintering in air at 900°C for 48 hours, grinding the sintered powder again, and sintering in air at 900°C for 48 hours, repeating three times to obtain Y123 with uniform and single composition Pure phase powder.

[0053] 3. The Y123 pure phase powder obtained in step 2, CaCO 3 Powder, CeO 2 Powder according to Y123+1wt%CaCO 3 +0.3wt%CeO 2 After fully grinding and mixing the ingredients, take 30g of the mixed powder and put it into a mold, and press it into a cylindrical precursor with a diameter of 30mm.

[0054] 4. Select a c-axis oriented NdBCO / YBCO / MgO thin film seed crystal material with a size of 2mm×2mm, where 2mm×2mm means that the length and wid...

Embodiment 3

[0063] A method for preparing a calcium-doped YBCO high-temperature superconducting quasi-single crystal, comprising the following steps:

[0064] 1. According to the ratio of Y:Ba:Cu=1:2:3, Y 2 o 3 、BaCO 3 Mix with CuO powder to obtain Y123 phase powder.

[0065] 2. After fully grinding the Y123 phase powder in step 1, sintering in air at 900°C for 48 hours, grinding the sintered powder again, and sintering in air at 900°C for 48 hours, repeating three times to obtain Y123 with uniform and single composition Pure phase powder.

[0066] 3. The Y123 pure phase powder obtained in step 2, CaCO 3 Powder, CeO 2 Powder according to Y123+15wt%CaCO 3 +1.5wt%CeO 2 After fully grinding and mixing the ingredients, take 10g of the mixed powder and put it into a mold, and press it into a cylindrical precursor with a diameter of 20mm.

[0067] 4. Select a c-axis oriented NdBCO / YBCO / MgO thin film seed crystal material with a size of 2mm×2mm, where 2mm×2mm means that the length and wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com