Iron-rich cold-set pellets and their manufacturing process and application

A technology for cold-solid pelletizing and manufacturing process, which is applied in the field of comprehensive utilization of resources and can solve the problems of affecting the pelletizing performance, strength and metal iron content of enriched sludge pellets, reducing the yield of metal iron, and weak anti-beating ability. , to achieve stable dephosphorization and desulfurization effect, reduce energy consumption, and achieve the effect of fast slag.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

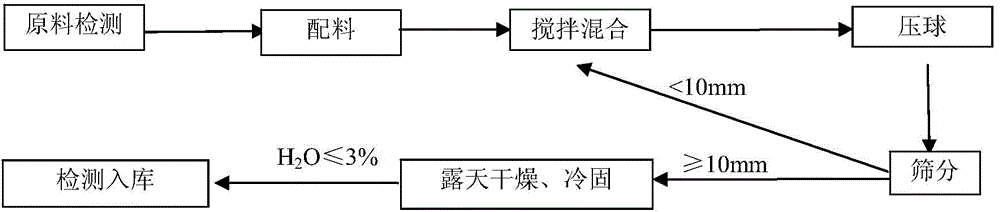

[0023] The manufacturing process of iron-rich chilled pellets of the present invention is characterized in that the steps are as follows:

[0024] (1) Prepare raw materials and pre-dry: use iron-rich sludge, binder, and soda ash as raw materials; control the water content of raw iron-rich sludge to 5-8%;

[0025] (2) Mixing: Mix the iron-rich sludge, binder, and soda ash, and stir until the raw materials are evenly mixed, and the non-stick stirring roller shall prevail to obtain the mixture;

[0026] (3) Ball pressing: the mixture obtained in step (2) is pressed into pellets; the pellets are sieved, and the sifted powder is continuously pressed to form pellets;

[0027] (4) Drying: The pellets obtained in step (3) are air-dried naturally, cooled and solidified to obtain the product. Among them, the freezing time is about 2-3 days. After meeting the moisture requirements, it should be put into storage, and rainproof measures should be taken during the open-air drying process,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crush indicators | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com