Method for preparing tire tread rubber by using modified microcrystalline cellulose

A technology of microcrystalline cellulose and tire tread, applied to special tires, tire parts, transportation and packaging, etc., can solve problems such as weak interface bonding strength, complex production process, and interfacial adhesion deviation, and improve processing Performance, simple preparation process, and the effect of reducing rolling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Utilize modified microcrystalline cellulose to prepare the method for tire tread rubber, its step comprises:

[0024] Using functional ionic liquid to modify microcrystalline cellulose: put 1g of allyl imidazolium chloride ([AMIM]Cl) ionic liquid, 100g of microcrystalline cellulose, and 300g of deionized water in a glass reactor, at 80°C Heating and stirring in a water bath for 3 hours, then drying the above-mentioned product after the stirring in a vacuum oven at 80°C for 12 hours, and cooling to obtain ionic liquid-modified microcrystalline cellulose; wherein the particle size of the microcrystalline cellulose is 20-80um.

[0025] Apply the modified microcrystalline cellulose to the reinforcing rubber process: mixing, mixing the base rubber with the ionic liquid modified microcrystalline cellulose in the internal mixer, the mixing starting temperature is 90 ° C, mixing The refining speed was 60 rpm, and then white carbon black was added, including 5 g of ionic liquid...

Embodiment 2

[0027] Utilize modified microcrystalline cellulose to prepare the method for tire tread rubber, its step comprises:

[0028] Using functional ionic liquid to modify microcrystalline cellulose: put 1g of allyl imidazolium chloride ([AMIM]Cl) ionic liquid, 100g of microcrystalline cellulose, and 300g of deionized water in a glass reactor, at 80°C Heating and stirring in a water bath for 3 hours, then drying the above-mentioned product after the stirring in a vacuum oven at 80°C for 12 hours, and cooling to obtain ionic liquid-modified microcrystalline cellulose; wherein the particle size of the microcrystalline cellulose is 20-80um.

[0029] Apply the modified microcrystalline cellulose to the reinforcing rubber process: mixing, mixing the base rubber with the ionic liquid modified microcrystalline cellulose in the internal mixer, the mixing starting temperature is 90 ° C, mixing The refining speed was 60 rpm, and then white carbon black was added, including 10 g of ionic liqui...

Embodiment 3

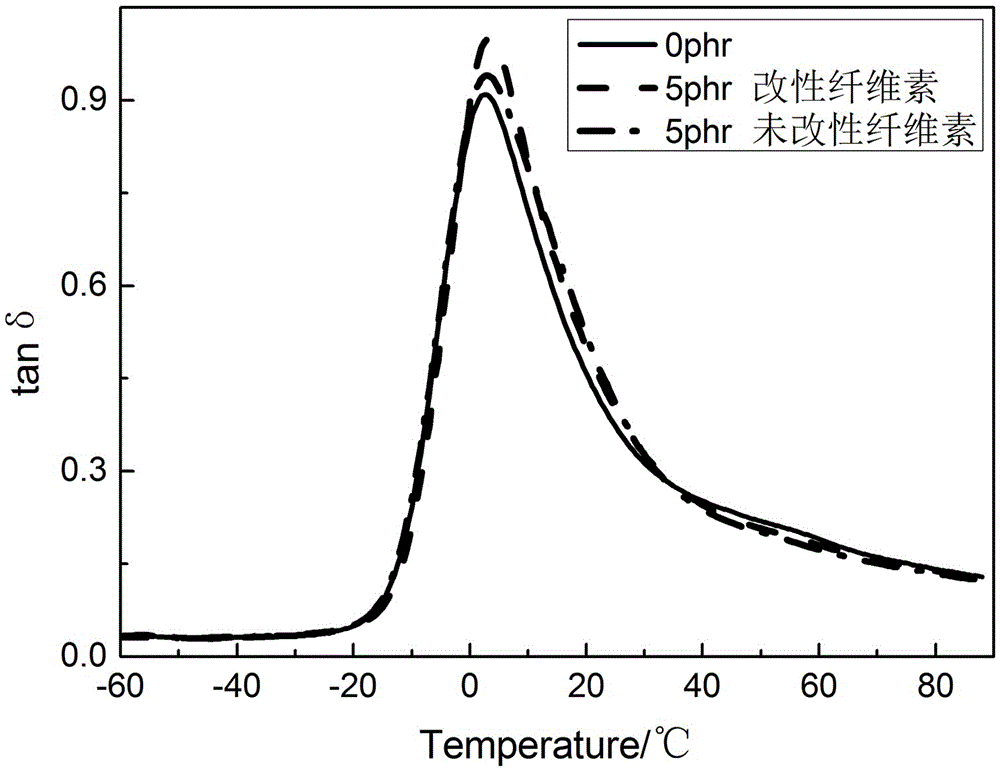

[0031] This example is a comparative example of Example 1, which differs from Example 1 in that the added microcrystalline cellulose is unmodified microcrystalline cellulose, and the added quality is the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com