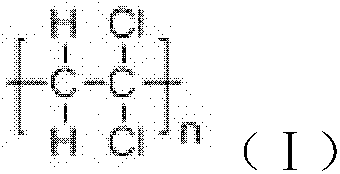

Polyvinylidene chloride (PVDC) emulsion and preparation method thereof as well as weather-proof barrier coating and application thereof

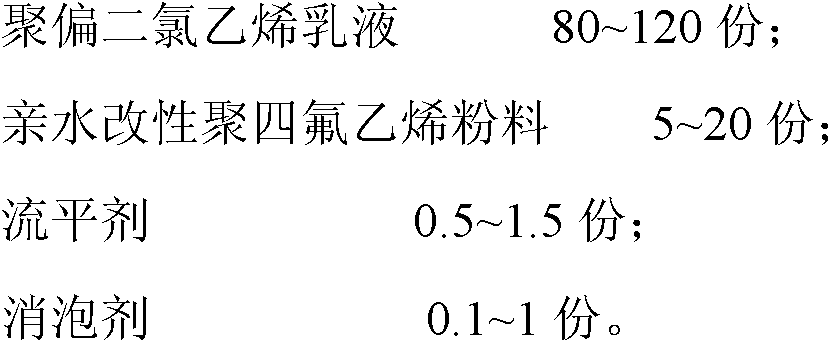

A technology of polyvinylidene chloride and vinylidene chloride, which is applied in the direction of coating, etc., can solve the problems of low adhesion, low molecular weight, and low crystallization temperature of barrier coatings, so as to improve adhesion, suppress side reactions, The effect of increasing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

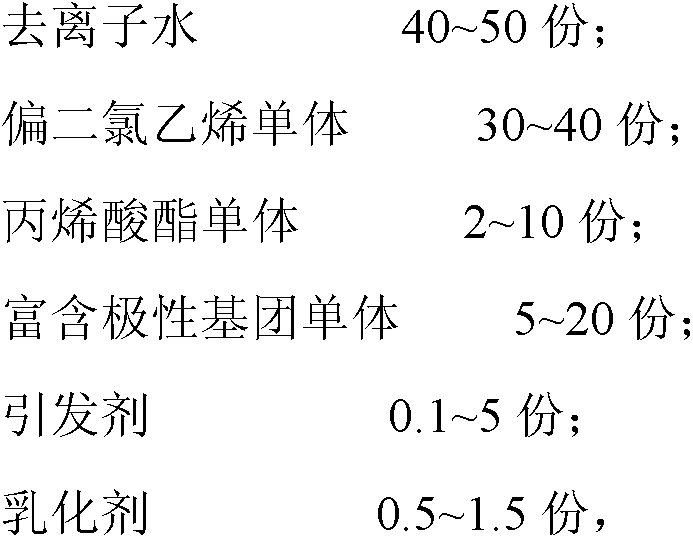

[0029] The molecular weight of the polyvinylidene chloride copolymer in the polyvinylidene chloride emulsion is closely related to its corresponding free radical activity, reaction temperature, reactant concentration, reaction vessel pressure (because the vinylidene chloride monomer is a gas), and stirring speed. . Therefore, in order to prepare ultra-high molecular weight (1.5×10 5 Above) polyvinylidene chloride emulsion of polyvinylidene chloride copolymer, the preparation method of polyvinylidene chloride emulsion of the present invention comprises the following steps: (a) pre-reaction: first vacuumize the reaction vessel and feed inert gas , then add the deionized water, initiator, polar group-rich monomer, acrylate monomer, and emulsifier in sequence, and then raise the temperature to 140-160°C under stirring conditions to maintain the pressure in the reaction vessel Keep the temperature at 0.2-1.2 MPa and feed the vinylidene chloride monomer in the formula amount, and c...

Embodiment 1

[0040] Polyvinylidene chloride emulsion raw material formula: deionized water 50kg, vinylidene chloride monomer 40kg, methyl methacrylate 10kg, diisopropyl peroxydicarbonate 0.1kg, sodium dodecylsulfonate 0.5kg, Cellulose acetate 0.5kg, dihydromyrcenyl ester monomer 5kg.

[0041] Preparation of polyvinylidene chloride emulsion:

[0042] (a) Pre-reaction: First vacuumize the pressure-resistant reactor with a volume of 100L and feed nitrogen, then add the above-mentioned quality deionized water, diisopropyl peroxydicarbonate, cellulose acetate, and dihydromyrcene in sequence Alcohol ester monomer, methyl methacrylate, sodium dodecylsulfonate, and then heated up to 160°C under the condition of stirring at a speed of 120 rpm, kept the pressure in the reaction vessel constant at 0.2MPa and introduced 40kg partial Dichloroethylene monomer (passing time is 1.5 to 3 hours), continue to react for 20 minutes;

[0043] (b) Cooling reaction: lower the temperature in the reaction vessel ...

Embodiment 2

[0049] Polyvinylidene chloride emulsion raw material formula: 40kg deionized water, 30kg vinylidene chloride monomer, 2kg ethyl methacrylate, 5kg dicyclohexyl peroxydicarbonate, 1.5kg sodium cetyl sulfonate, acetic acid 0.5 kg of cellulose, 5 kg of dihydromyrcenyl ester monomer, and 10 kg of 2,2-dimethyl-4-pentenyl ester.

[0050] Preparation of polyvinylidene chloride emulsion:

[0051] (a) Pre-reaction: first vacuumize the pressure-resistant reactor with a volume of 100L and pass it into argon, then add the above-mentioned quality of deionized water, dicyclohexyl peroxydicarbonate, cellulose acetate, and dihydrolauryl in sequence Enol ester monomer, 2,2-dimethyl-4-pentenol ester, ethyl methacrylate, sodium hexadecylsulfonate, and then heated to 140 under the stirring condition of 80 rpm ℃, keep the pressure in the reaction vessel constant at 1.2 MPa and feed 30 kg of vinylidene chloride monomer (the feeding time is 1.5 to 3 hours), and continue the reaction for 40 minutes; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com