Passive residual heat exhausting system of pressurized water reactor nuclear power plant

A pressurized water reactor nuclear power plant, passive waste heat technology, applied in the field of safety systems, can solve problems such as leakage, high requirements for heat exchangers, and the addition of radioactive coolant in the primary circuit, so as to ensure safety, improve heat exchange efficiency, reduce volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

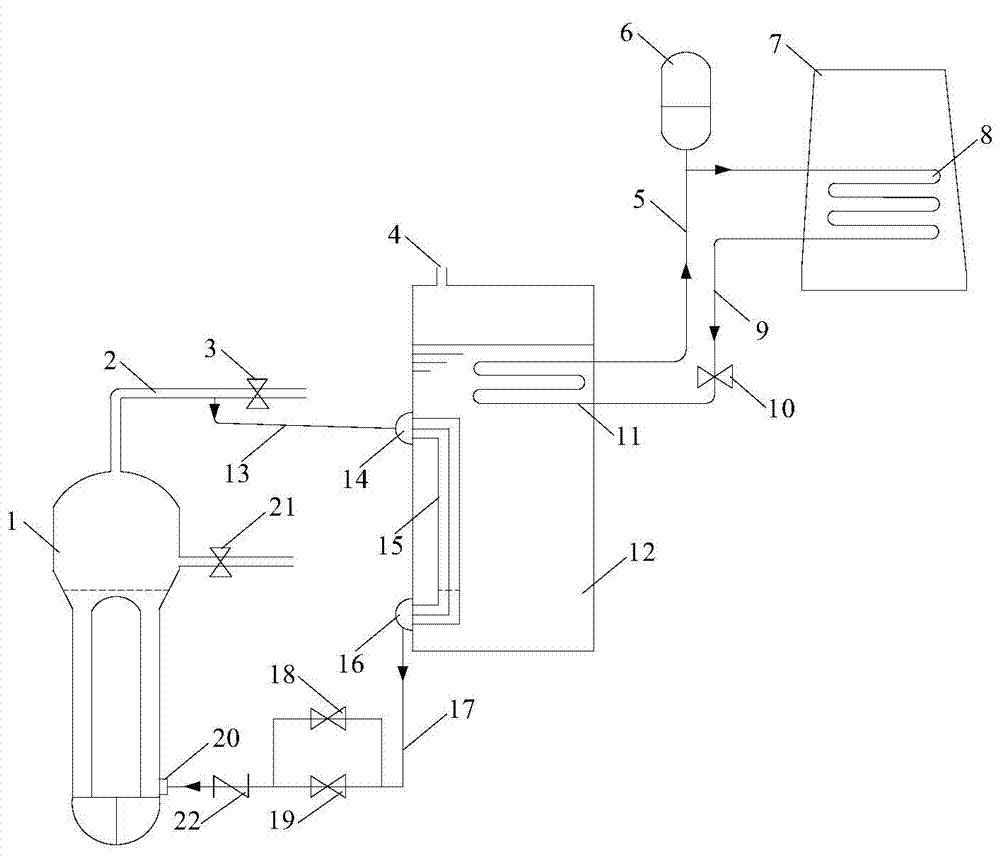

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

[0025] The passive waste heat discharge system of the pressurized water reactor nuclear power plant shown in the accompanying drawings includes a passive waste heat export system and a passive emergency water tank cooling system. The passive waste heat export system consists of a steam pipe 13, a passive discharge heat exchanger 15 and a condensate pipe 17 Composition, the passive waste heat discharge heat exchanger 15 is located at the lower part of the emergency cooling water tank 12; the passive waste heat discharge heat exchanger 15 is a group of C-shaped cooling pipes, and the inlet of the C-shaped cooling pipe is the steam chamber 14, and the steam chamber 14 is connected with the steam pipe 13, and the outlet of the C-type cooling pipe is the condensate chamber 16, the altitude of which is slightly lower than the water level of the steam generator 1, and is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com