Handheld electric welding machine

An electric welding machine and hand-held technology, which is applied to arc welding equipment, cleaning torches, welding equipment, etc., can solve the problems of high surface temperature, inconvenient multi-directional electric welding work, and the safety impact of electric welding work by staff. Improve safety, improve stability, and meet the effect of cleaning and cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the objects and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the examples. It should be understood that the following words are only used to describe a hand-held electric welding machine or several specific implementations of the present invention, and are not intended to Strictly defining the scope of protection specifically claimed by the present invention, as used herein, the terms up-down and left-right are not limited to their strict geometric definitions, but rather include reasonable and inconsistent tolerances for machining or human error, as detailed below The specific characteristics of this hand-held electric welding machine:

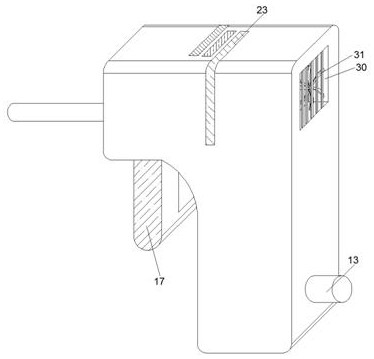

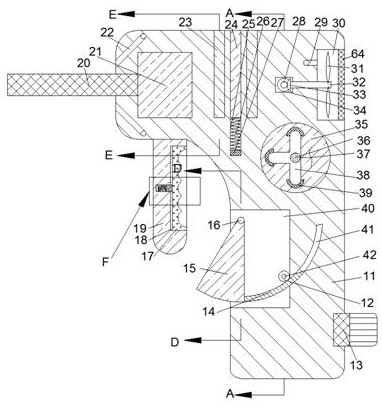

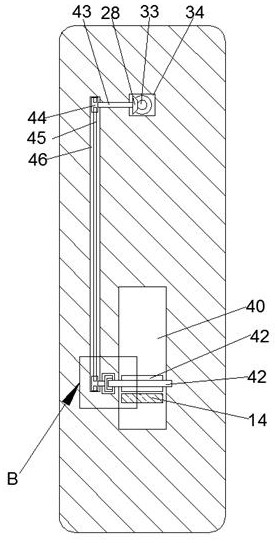

[0023] refer to Figure 1-8 , a hand-held electric welding machine according to an embodiment of the present invention, comprising an electric welding machine main body 11, an electric welding device 21 is fixedly arranged on the left side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com