Method for modifying polyetheretherketone surface by implanting tantalum ions and modified polyetheretherketone material

A technology of polyether ether ketone and ion pair, which is applied in the field of polyether ether ketone materials, can solve problems such as poor biocompatibility, achieve strong stability and biological safety, improve biocompatibility, and osseointegration properties Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] After the pure polyether ether ketone of 10mm×10mm×1mm has been polished, it is cleaned by ultrasonic cleaning with acetone and deionized water in sequence, each time for 30 minutes, after cleaning, it is dried in an oven at 80°C and stored properly. Plasma immersion ion implantation technology was used to implant tantalum ions into the polyetheretherketone matrix (Ta-1), and the modified polyetheretherketone material was properly preserved. The specific process parameters are shown in Table 1:

[0049] Table 1 Tantalum ion implantation parameters:

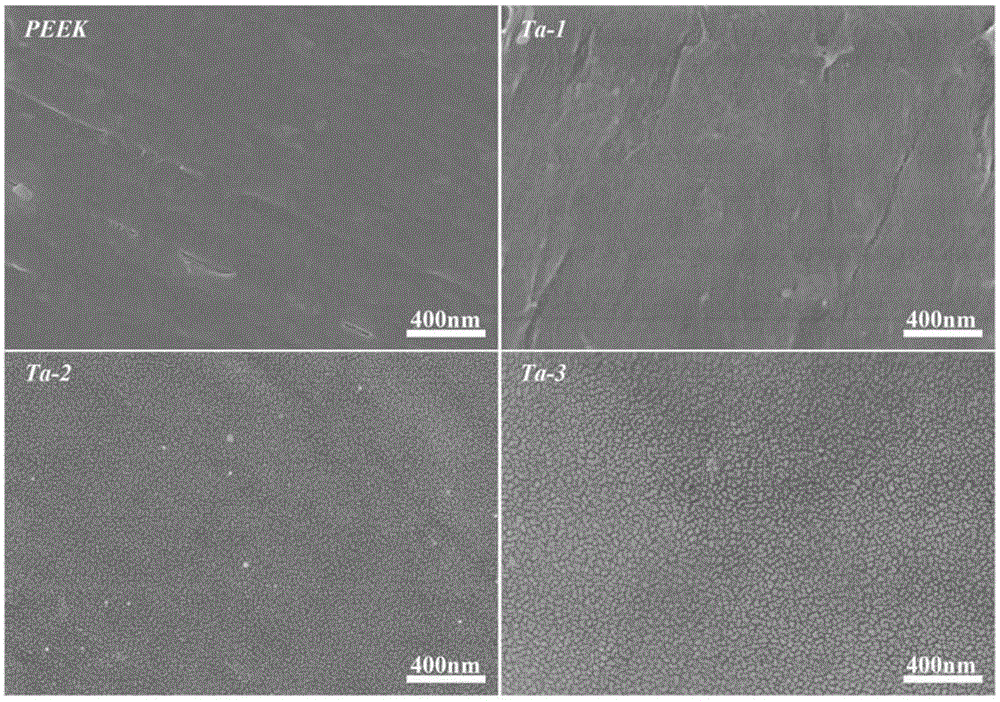

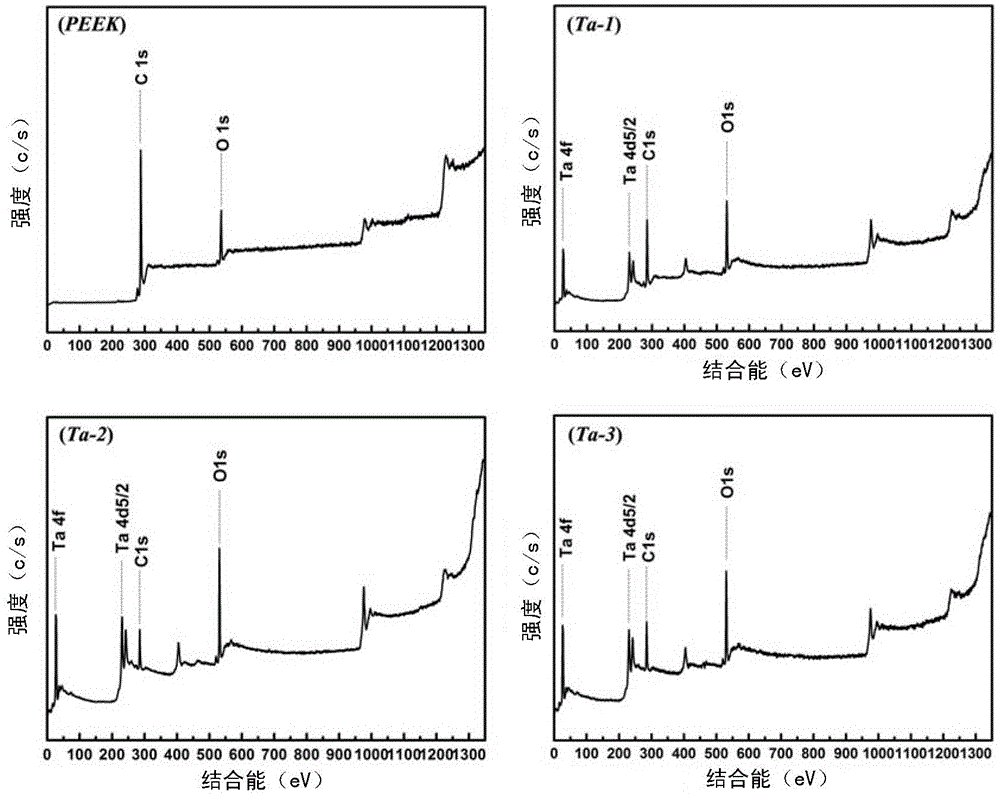

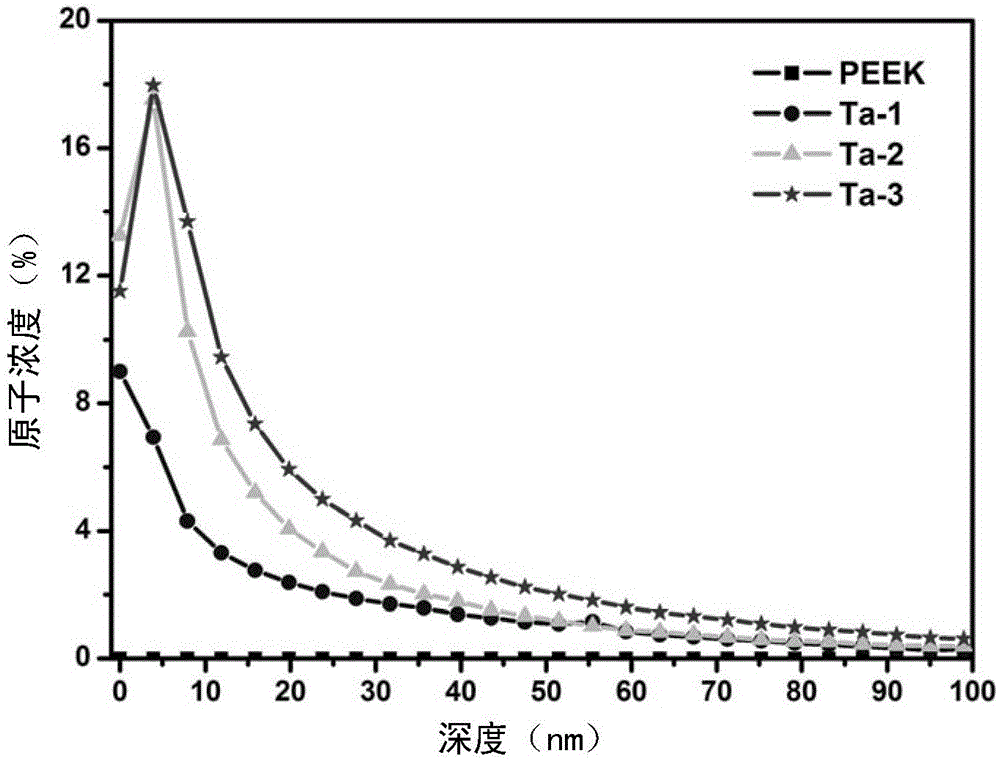

[0050] Injection voltage (kV)

[0051] figure 1 Ta-1 in the figure is the surface morphology diagram of the medical polyether ether ketone material obtained through the modification treatment in this example, which shows that the surface of the modified material has extremely small nanoparticles, the size of which is about several nanometers; figure 2 Ta-1 in the above is the XPS full-spectrum spectrum of the su...

Embodiment 2

[0053] After the pure polyether ether ketone of 10mm×10mm×1mm has been polished, it is cleaned by ultrasonic cleaning with acetone and deionized water in sequence, each time for 30 minutes, after cleaning, it is dried in an oven at 80°C and stored properly. Plasma immersion ion implantation technology was used to implant tantalum ions into the polyetheretherketone matrix (Ta-2), and the modified polyetheretherketone material was properly preserved. The specific process parameters are shown in Table 2:

[0054]Table 2 Tantalum ion implantation parameters:

[0055] Injection voltage (kV)

[0056] figure 1 Ta-2 in the figure is the surface morphology diagram of the medical polyether ether ketone material obtained through the modification treatment of this example. The figure shows that the modified material has nanoparticles on the surface, and the size is larger than Ta-1, about 10 nanometers ; figure 2 Ta-2 in this example is the XPS full-spectrum spectrum of the s...

Embodiment 3

[0058] After the pure polyetheretherketone of 10mm×10mm×1mm is polished, it is ultrasonically cleaned with acetone and deionized water in sequence, each time for 30 minutes, after cleaning, it is dried in an oven at 80°C and stored properly. Plasma immersion ion implantation technology was used to implant tantalum ions into the polyether ether ketone matrix (Ta-3), and the modified polyether ether ketone material was properly preserved after implantation. The specific process parameters are shown in Table 3:

[0059] Table 3 Tantalum ion implantation parameters:

[0060] Injection voltage (kV)

[0061] figure 1 Ta-3 in the figure is the surface morphology diagram of the medical polyether ether ketone material obtained through the modification treatment in this example. The figure shows that the modified material has nanoparticles on the surface, and the size is larger than that of Ta-1 and Ta-2. About 10-20 nanometers; figure 2 Ta-3 in this example is the XPS full...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com