Method for preparing non-oriented electrical steel for high-efficient motor via twin roll strip casting

A technology of twin-roll thin strip continuous casting and oriented electrical steel, which is applied in the field of metallurgy and can solve the problems of low magnetic induction of finished products, limited improvement of magnetic induction, and insufficient efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

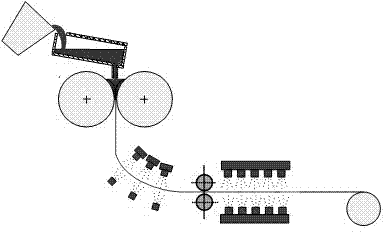

[0030] A method for preparing non-oriented electrical steel for high-efficiency motors by twin-roll strip continuous casting, such as figure 1 shown, follow the steps below:

[0031](1) According to the mass percentage of chemical composition: 0.0034%C, 1.31%Si, 0.32%Mn, 0.25%Al, and limit 0.0043%O, 0.005%S, 0.0045%N, the rest is Fe smelting molten steel;

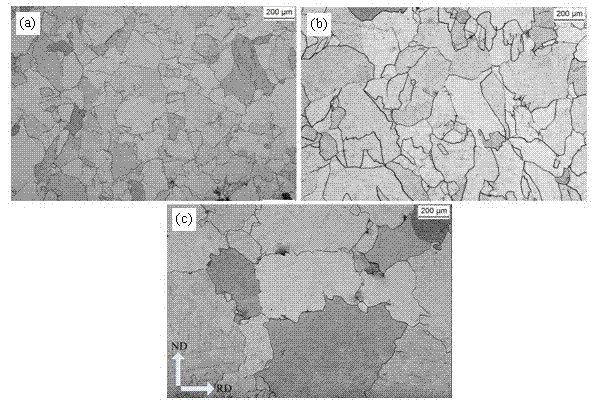

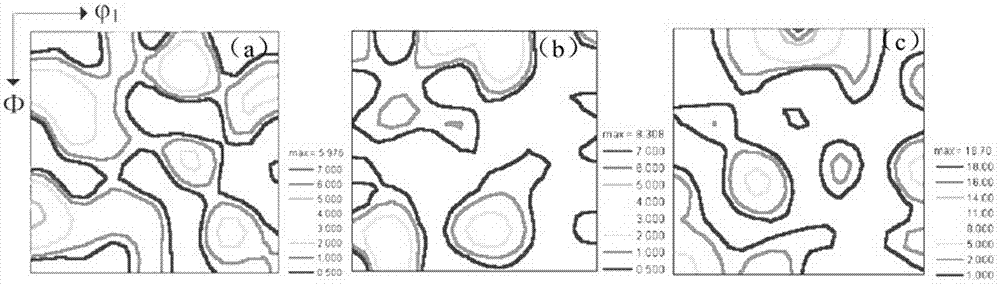

[0032] (2) Control the pouring temperature at 1540°C, pour the molten steel into the rotating steel roll through the tundish, and quickly solidify and form it to obtain a cast strip with a thickness of 2.5mm and a coarse and uniform structure. The metallographic structure of the cast strip is as follows: figure 2 As shown in (a), the grain size is 98 μm, and the grain orientation is as image 3 As shown in (a), the {100} component in the crystal orientation of the cast strip is significantly increased;

[0033] (3) Cool the cast strip, control the initial cooling temperature at 1308°C, and the final cooling temperat...

Embodiment 2

[0036] A method for preparing non-oriented electrical steel for high-efficiency motors by twin-roll strip continuous casting, such as figure 1 As shown, follow the following steps: (1) According to the mass percentage of chemical composition: 0.0031%C, 1.30%Si, 0.33%Mn, 0.27%Al, and limit 0.0042%O, 0.005%S, 0.0041%N, the rest is Fe molten steel;

[0037] (2) Control the pouring temperature at 1560°C, pour the molten steel into the rotating steel roll through the tundish, and quickly solidify and form it to obtain a cast strip with a thickness of 2.5mm and a coarse and uniform structure. The metallographic structure of the cast strip is as follows: figure 2 As shown in (b), the grain size is 160 μm, and the grain orientation is as image 3 As shown in (b), the {100} component in the crystal orientation of the cast strip is significantly increased;

[0038] (3) Cool the cast strip, control the initial cooling temperature at 1315°C, and the final cooling temperature at 960°C, ...

Embodiment 3

[0041] A method for preparing non-oriented electrical steel for high-efficiency motors by twin-roll strip continuous casting, such as figure 1 As shown, follow the following steps: (1) According to the mass percentage of chemical composition: 0.0035%C, 1.32%Si, 0.30%Mn, 0.24%Al, and limit 0.0046%O, 0.0039%S, 0.0041%N, the rest is Fe molten steel;

[0042] (2) Control the pouring temperature at 1580°C, pour the molten steel into the rotating steel roll through the tundish, and quickly solidify and form it to obtain a cast strip with a thickness of 2.5mm and a coarse and uniform structure. The metallographic structure of the cast strip is as follows: figure 2 As shown in (c), the grain size is 380 μm, and the grain orientation is as image 3 As shown in (c), the {100} component in the crystal orientation of the cast strip is significantly increased;

[0043] (3) Cool the cast strip, control the initial cooling temperature to 1320°C, and the final cooling temperature to 980°C,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Grain | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com